Process for preparing aliphatic ester

The technology of fatty acid ester and process method is applied in the field of preparation of fatty acid ester, can solve the problems of complex process and high energy consumption, and achieve the effects of improving conversion rate, improving selectivity and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

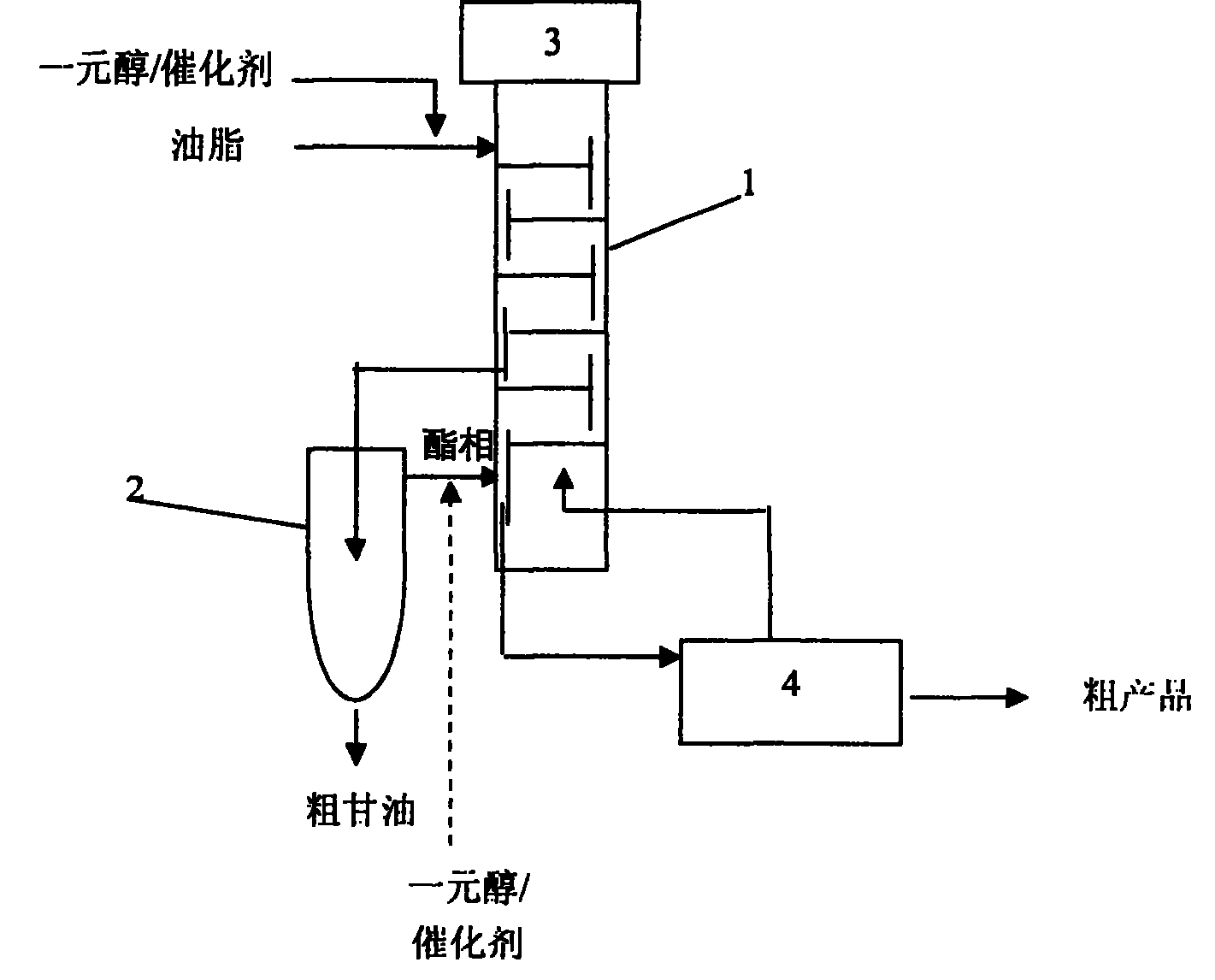

[0029] The reaction device is the same as in Comparative Example 1, but a 500mL glycerin settling tank is connected to the outlets of the 10th and 15th trays, and the ester phase after the glycerin is separated enters the next tray to continue the reaction after supplementing catalyst and monohydric alcohol. . On the first tray, feed oil 430g / h, 2.69% KOH-methanol solution 30g / h, respectively add methanol solution 25g / h and 9g / h on the 10th and 15th tray. After the product was flashed with methanol, the ester phase was analyzed, and it contained 0.9% monoglyceride, and no diglyceride and triglyceride were detected.

Embodiment 2

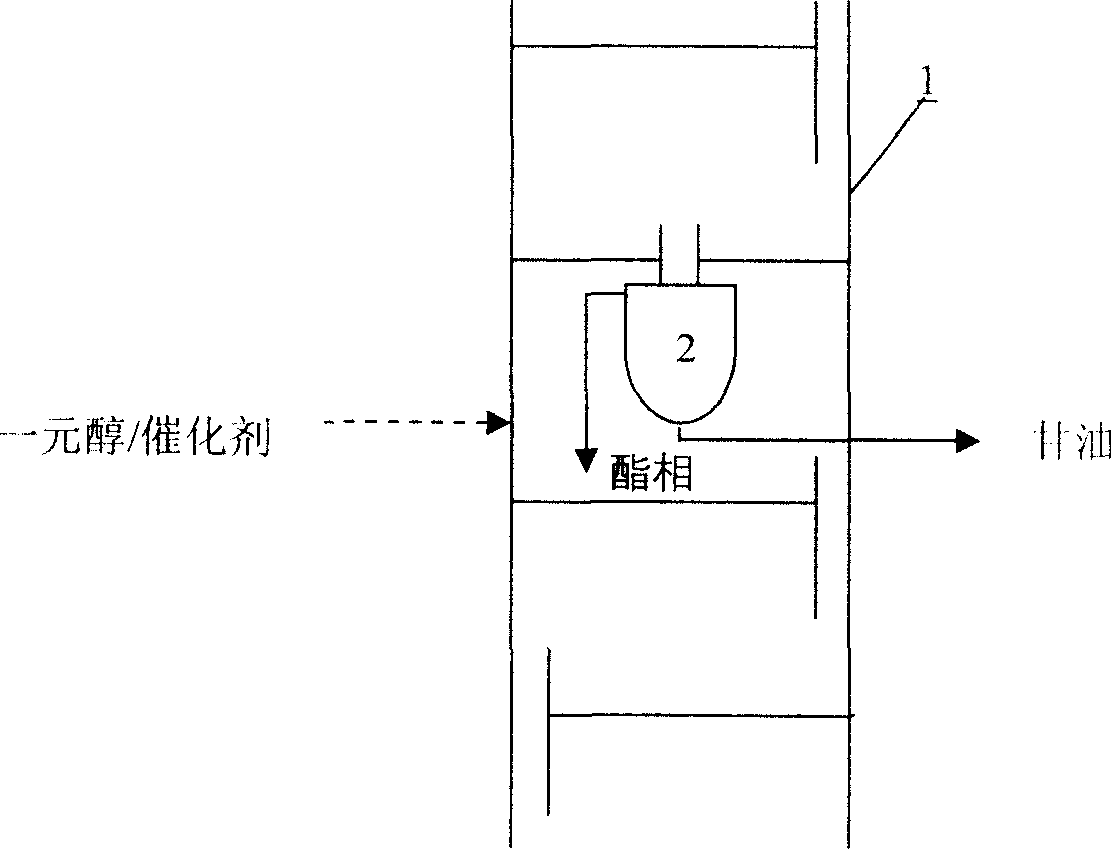

[0031] The reaction device is the same as Comparative Example 1, but on the 10th column plate, it is connected with such figure 2 In the 200mL glycerin settling tank shown in , the ester phase after the glycerol is separated enters the next tray to continue the reaction after replenishing the catalyst and monohydric alcohol. On the first tray, 430g / h of grease and 40g / h of 2.69% KOH-methanol solution are introduced, and 24g / h of methanol solution is added to the ester phase after separation of glycerin. After the product was flashed with methanol, the ester phase was analyzed, containing 1.2% of monoglyceride, 0.5% of diglyceride, and no triglyceride was detected.

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com