Organic pressure sensor and its use method

A pressure sensor, an organic technology, applied in the field of sensors, can solve the problems of large volume, heavy weight, and pressure sensing components that cannot be further miniaturized, and achieve the effect of high sensitivity and easy realization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

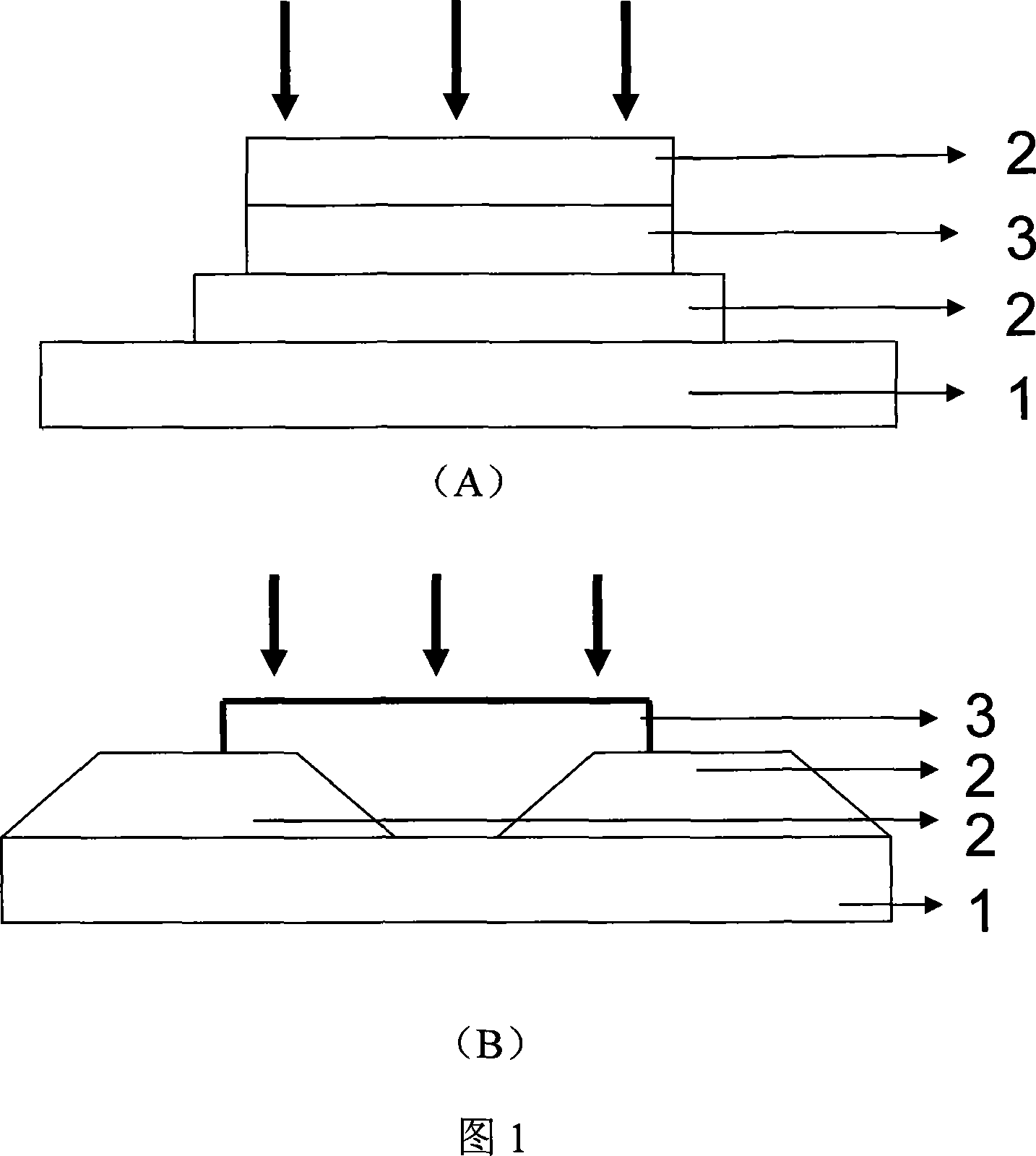

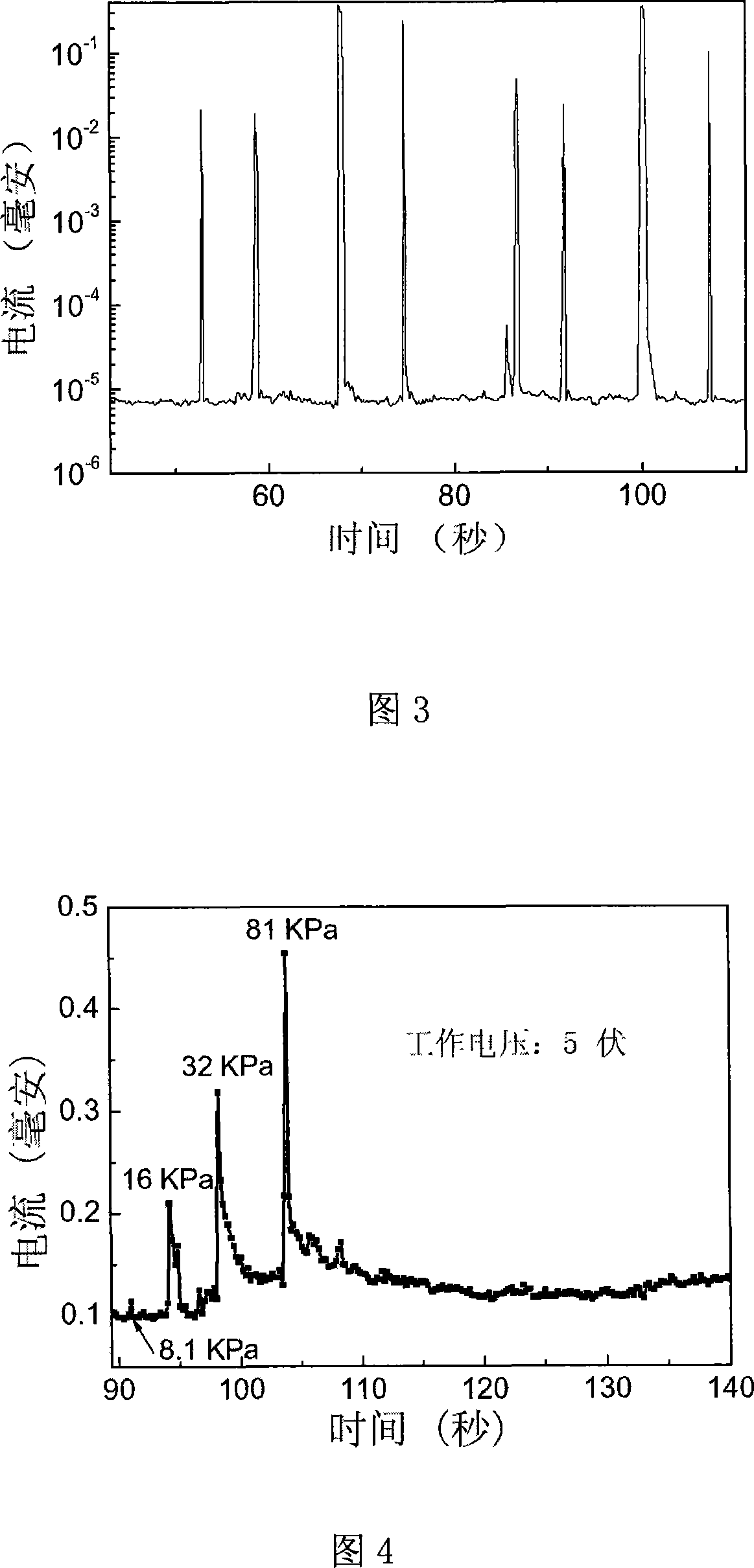

[0026] Embodiment 1, as shown in Figure 1, on the ITO electrode that takes glass as substrate, evaporate the organic small molecule material Alq of 70 nanometers thick with vacuum evaporation method, then evaporate the aluminum electrode (as shown in Figure 2) of 140 nanometers thick (A)), with ITO as the anode, aluminum as the cathode, plus a DC voltage of 0.1V, using a 100-gram weight as the applied pressure, the device area is 3 × 4 mm, using a silicon chip with a size of 0.88 × 0.69 cm A piece of rubber was covered with 0.1 mm thick rubber as a medium for uniformly applying pressure, and the change of current passing through the device over time was measured. The process of applying pressure was performed manually, and the duration was about 0.2 seconds, and the longest did not exceed 0.8 seconds. The relationship of current variation with time can be obtained as shown in Figure 3. It can be seen that the sensitivity of the device is very high, and the magnitude of the curr...

Embodiment 2

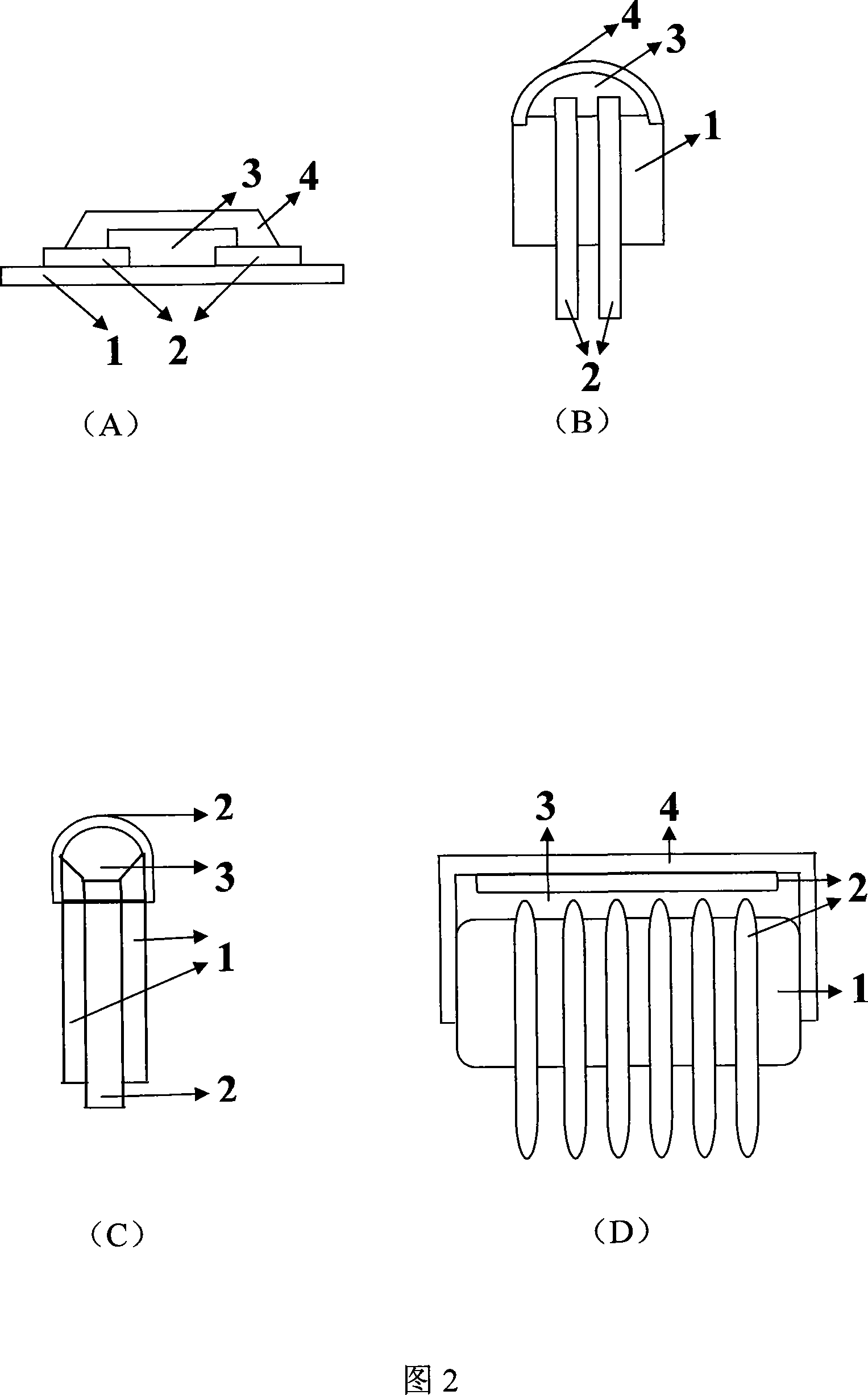

[0027] Example 2, as shown in FIG. 2(A), the structure of the organic pressure sensor is ITO / Alq(60nm) / Al(160nm), and the current varies with time under a fixed voltage (5V). There is a significant increase in current at certain moments when the pressure indicated in the figure is applied. By changing the methods and conditions of preparation and testing, changing the structure and materials of the device, etc., the performance of the device can be further optimized.

Embodiment 3

[0028] Embodiment 3, as shown in Figure 2 (B), etches a trench on the ITO glass, the trench width is controlled between 0.1 ~ 10 microns, evaporates and deposits an organic thin film Alq with a thickness of 500nm, and uses a polished silicon wafer Covering the film and applying pressure on it, it can be tested that there is an obvious piezoresistive characteristic between the two electrodes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com