Portable DC charging pile fault test system and detection method thereof

A technology for DC charging piles and fault testing, which is applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., to achieve the effects of improving detection efficiency, shortening detection time, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

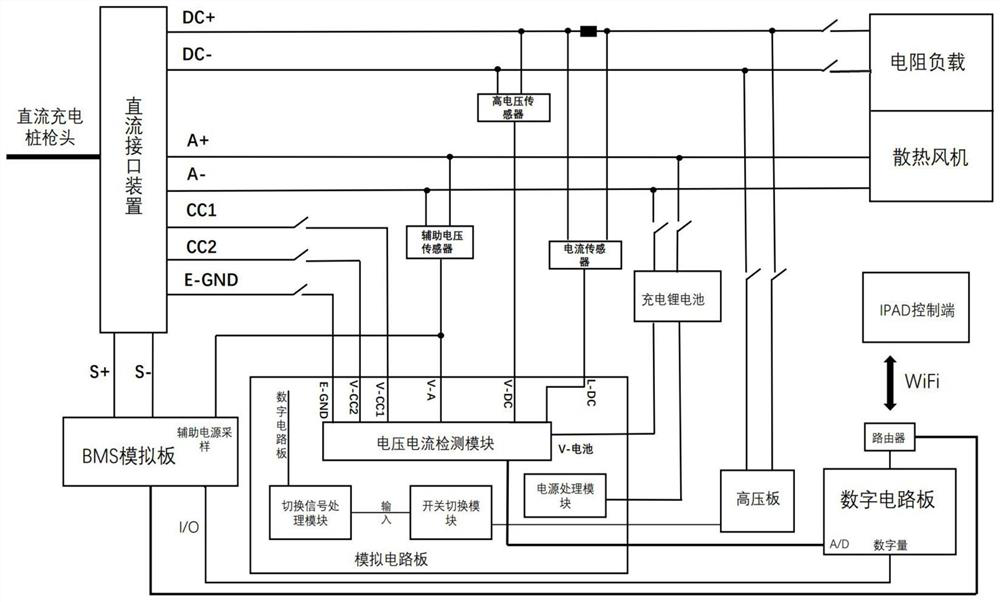

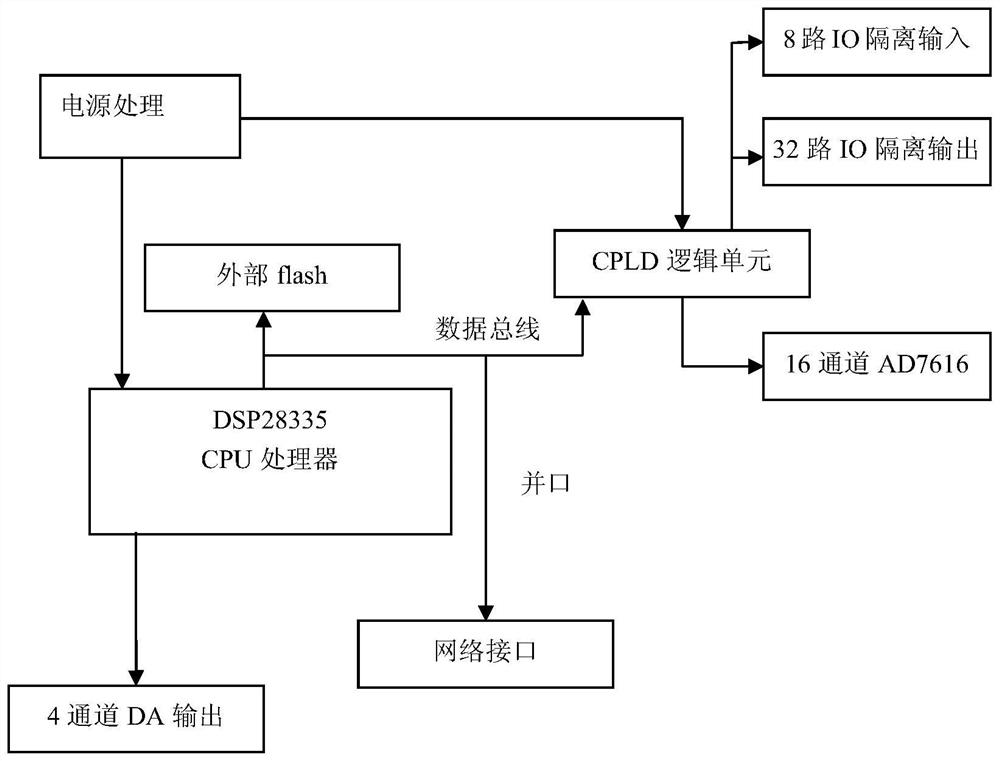

[0031] Embodiment 1: as Figure 1-3 As shown, a portable DC charging pile fault test system includes a DC charging pile detection terminal, and the DC charging pile detection terminal includes a DC interface device for plugging in the DC charging pile gun head, a BMS simulation board, a simulation circuit board, and a high voltage board. and digital circuit board, high voltage board is used to simulate battery power supply, DC interface device is connected to load, BMS analog board and analog circuit board, high voltage board is connected to analog circuit board and load input, analog circuit board is connected to digital circuit board and load , The load uses a 7.5kw resistive load.

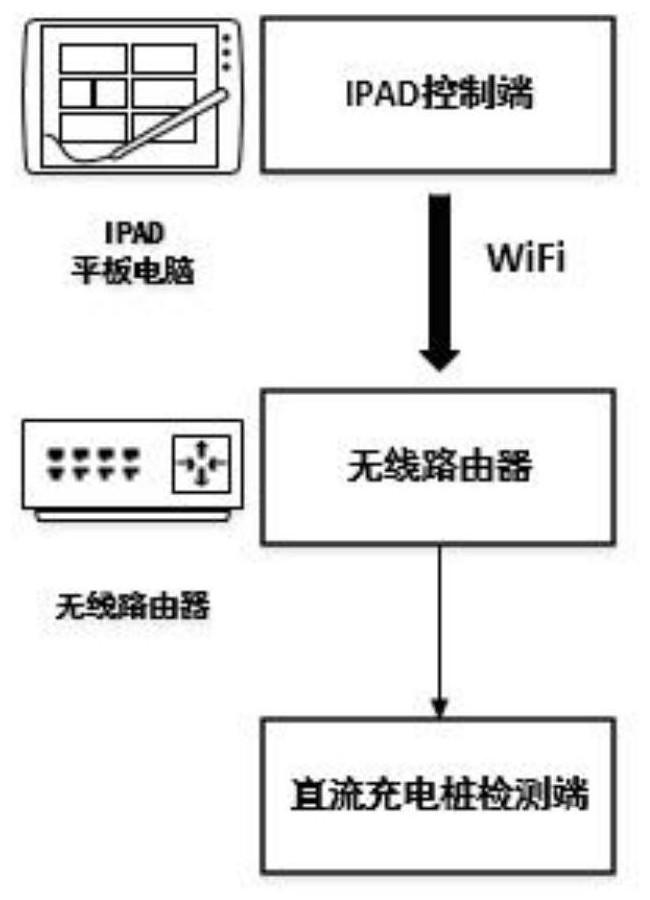

[0032] Preferably, the above-mentioned portable DC charging pile fault test system also includes an IPAD control terminal, and the IPAD control terminal is connected to the DC charging pile detection terminal (specifically a digital circuit board and a BMS analog board) through a wireless module...

Embodiment 2

[0046] Embodiment 2: A test method of a portable DC charging pile fault test system, the method includes the following steps:

[0047] S1. Turn on the power supply of the detection terminal of the DC charging pile, open the supporting control software in the IPAD control terminal, connect to the detection terminal of the DC charging pile through the wireless module, and enter the main interface of the software system;

[0048] S2, the detection operation method steps are as follows:

[0049] Step 1: First connect the charging gun of the charging pile to the DC interface device at the detection end of the DC charging pile;

[0050] Step 2: Input the basic information of the checked charging pile through the system software parameter setting interface in the IPAD control terminal. The basic information of the checked charging pile includes the name of the device, the specification and model of the DC charging pile, the output voltage range of the DC charging pile, the output cur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com