Waterproof power cable and its manufacturing method

A technology for power cables and manufacturing methods, applied to power cables with shielding layers/conductive layers, cable/conductor manufacturing, circuits, etc., which can solve the problems of increased cable costs, expensive water-blocking ropes, and unstable longitudinal water-blocking performance of cables and other problems, to achieve the effect of increased cost, excellent water resistance and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Through the following examples, the substantive characteristics and remarkable progress of the present invention are further illustrated, but the present invention is by no means limited to the examples.

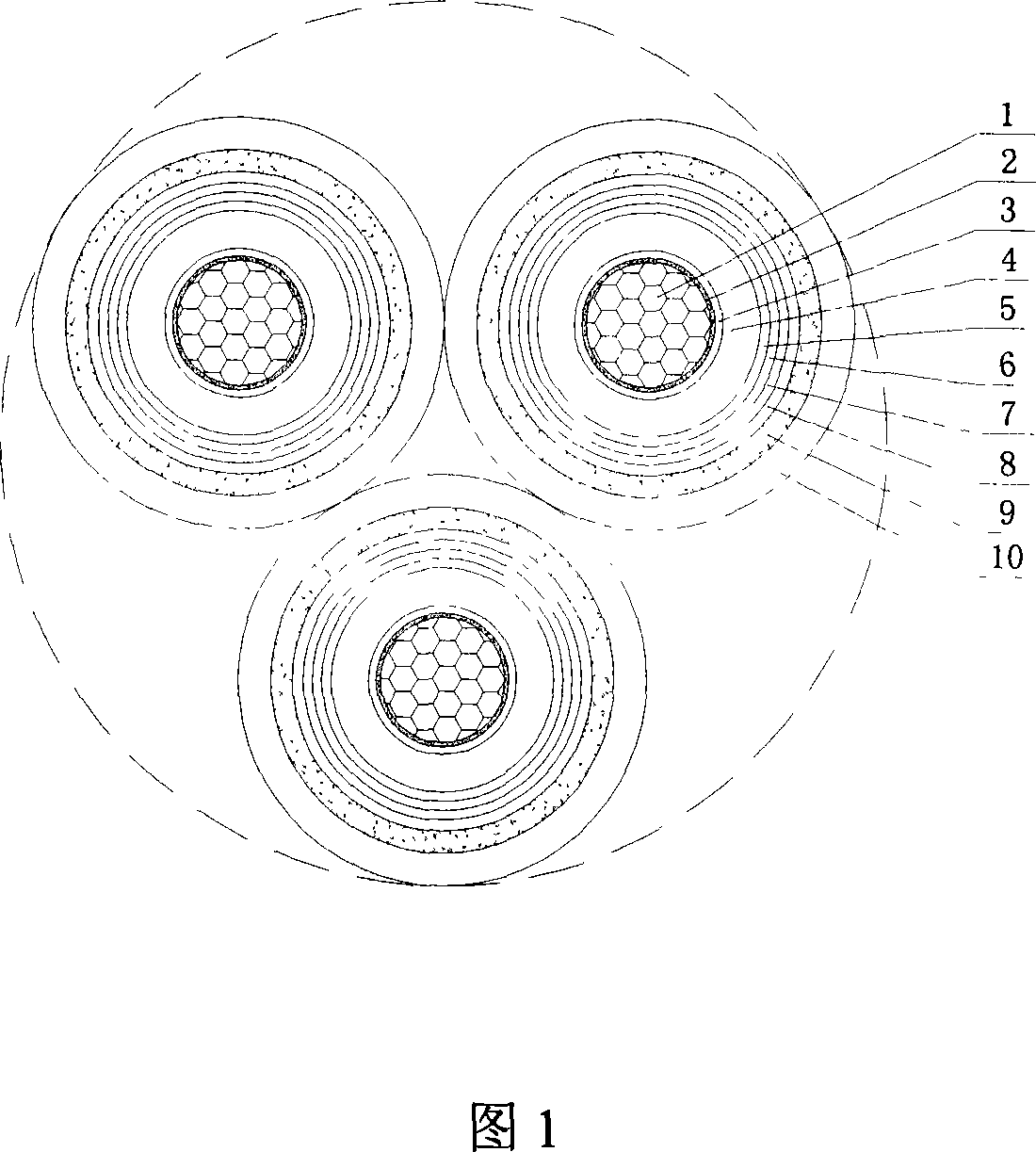

[0033] The waterproof power cable described in this embodiment is shown in Figure 1. It is composed of three single-core water-blocking cables twisted into cables. Each single-core water-blocking cable is composed of conductors, water-blocking powder, conductor shielding layer, Insulation layer, insulating layer shielding layer, semiconductor water blocking tape I, metal shielding layer, semiconductor water blocking tape II, water blocking layer and outer protective layer.

[0034] 1. Conductor:

[0035] Oxygen-free copper wire is used, which meets the requirements for the structure of Class 2 conductors specified in the GB / T3956 standard. The conductor adopts a layered compact structure, and the surface of each layer needs to be coated with water-blocking powder to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com