Production of deodorant

A deodorant and Chinese herbal medicine technology, applied in the field of deodorant preparation, can solve the problems of environmental pollution and low deodorization efficiency, and achieve remarkable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

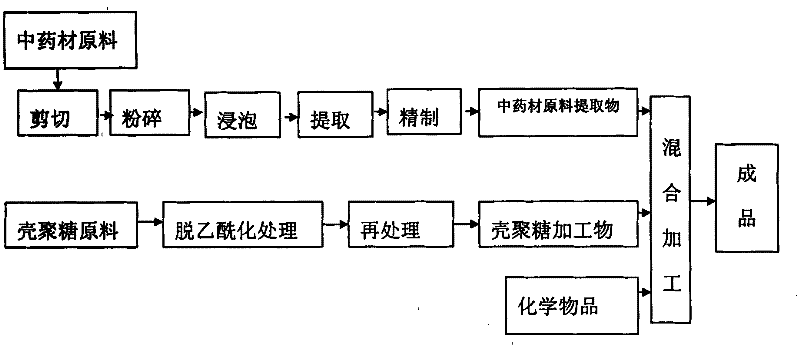

Image

Examples

Embodiment 1

[0014] Take 1.5 kg of leaves and stems of mugwort, 2.5 kg of Daqingye, 4.8 kg of comfrey, 6 kg of gentian, 2.2 kg of calamus, 3.6 kg of herb, 2.4 kg of scutellaria baicalensis, 0.5 kg of Phellodendron cork, and 4 kg of coptis, and cut them , crushing, soaking with methanol, extraction, refining and other processes, and then as a semi-finished product, sealed and sealed for fermentation, fermented until the content of the single active ingredient is between 0.001% and 10%, and the total content is between 1-20%, and the finished product of Chinese medicinal materials is obtained , use high performance liquid chromatography to measure the peak of effective substances, calculate the peak area of individual substances to obtain the content of individual substances, and calculate the total area to obtain the total content.

[0015] Deacetylate chitosan to make the deacetylation of chitosan more than 70%, carry out methylation and reprocessing, and then prepare an aqueous solution ...

Embodiment 2

[0018] Take 0.8 kg of leaves and stems of mugwort, 5.4 kg of Daqingye, 3.8 kg of comfrey, 3.2 kg of gentian, 0.5 kg of calamus, 3 kg of herb, 2 kg of skullcap, 3 kg of Phellodendron, and 2.5 kg of coptis, and cut them , crushing, soaking with ethanol, extraction, refining and other processes, and then as a semi-finished product, sealed and sealed for fermentation, fermented until the content of the single active ingredient is between 0.001% and 10%, and the total content is between 1-20%, and the finished product of Chinese medicinal materials is obtained , use high performance liquid chromatography to measure the peak of effective substances, calculate the peak area of individual substances to obtain the content of individual substances, and calculate the total area to obtain the total content.

[0019] Deacetylate chitosan to make the deacetylation of chitosan more than 70%, carry out methylation and reprocessing, and then prepare an aqueous solution with a concentration of...

Embodiment 3

[0022] Take 6 kg of leaves and stems of mugwort, 0.8 kg of Daqingye, 3.2 kg of comfrey, 4 kg of gentian, 1.5 kg of calamus, 2.8 kg of herb, 4 kg of skullcap, 3.2 kg of Phellodendron cortex, and 3.4 kg of coptis, and cut them , crushing, soaking in acetone, extraction, refining and other processes, and then as a semi-finished product, it is sealed and fermented, and fermented until the content of the single active ingredient is between 0.001% and 10%, and the total content is between 1-20%, and the finished product of Chinese medicinal materials is obtained , use high performance liquid chromatography to measure the peak of effective substances, calculate the peak area of individual substances to obtain the content of individual substances, and calculate the total area to obtain the total content.

[0023] Deacetylate chitosan to make the deacetylation of chitosan more than 70%, carry out methylation and reprocessing, and then prepare an aqueous solution with a concentration o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com