Method and system for recovering, reutilizing and treating electroplating water

A treatment method and full recovery technology, applied in water/sewage treatment, metallurgical wastewater treatment, adsorption water/sewage treatment, etc., can solve problems such as non-compliance with discharge standards, increased treatment costs, and inability to directly reuse, etc., to save tap water and water charges, reduced treatment links, low use and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

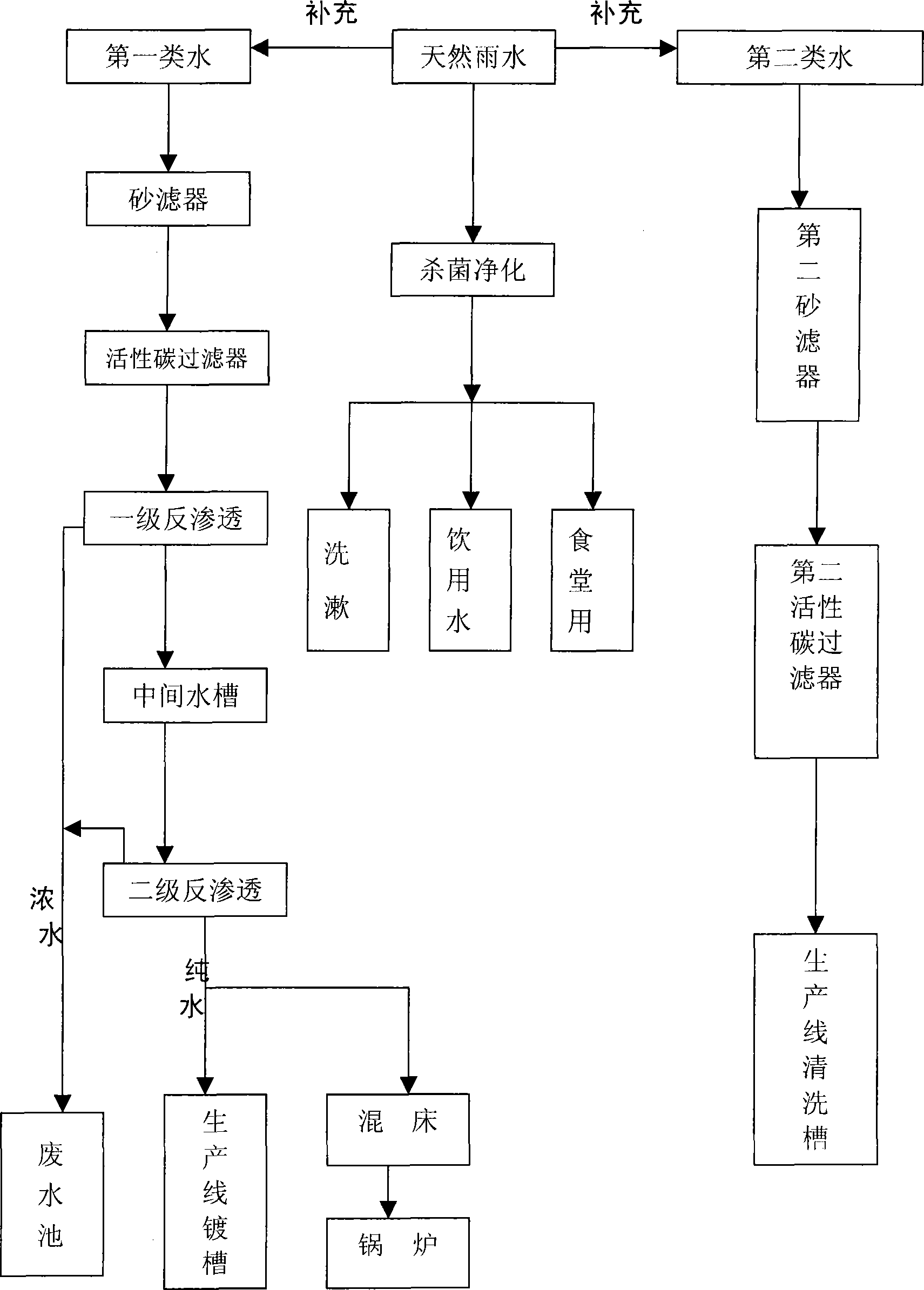

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0020] The electroplating water recovery treatment method of the present invention collects the electroplating water that has been treated by the pretreatment system and has reached the national environmental discharge standard into two types, the first type of water is obtained by treating wastewater containing chromium, nickel, copper or other metals Discharge standard water, this type of wastewater includes rinsing water from chrome plating or nickel or copper production lines, plating tank water or surface water spilled on the ground, which accounts for about 1 / 5-2 / 5 of the total production water consumption. They are sorted and collected into a storage tank. The heavy metal content in this part of the treated water is less than 1.6 milligrams, which has fully met the discharge standards stipulated by the state. However, because it contains part of the salt and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com