Method and apparatus for inspecting and controlling X-ray probe

A technology of detection control and control method, applied in the direction of using radiation for material analysis, special data processing applications, instruments, etc., can solve the problems of wasting materials, unable to know the radiation dose rate and cumulative dose, time-consuming and labor-intensive, etc., to reduce the workload , the effect of reducing the loss of film material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

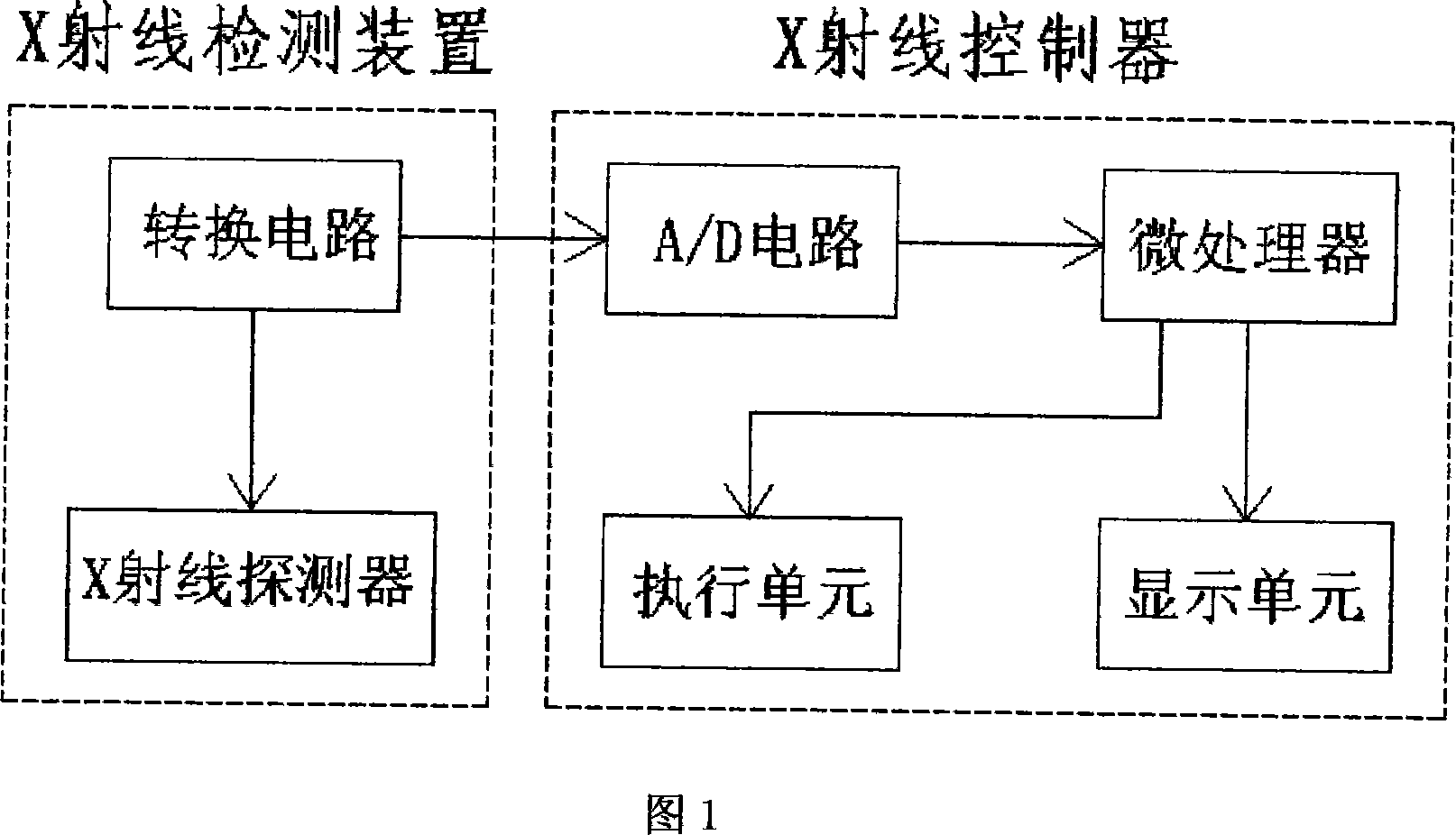

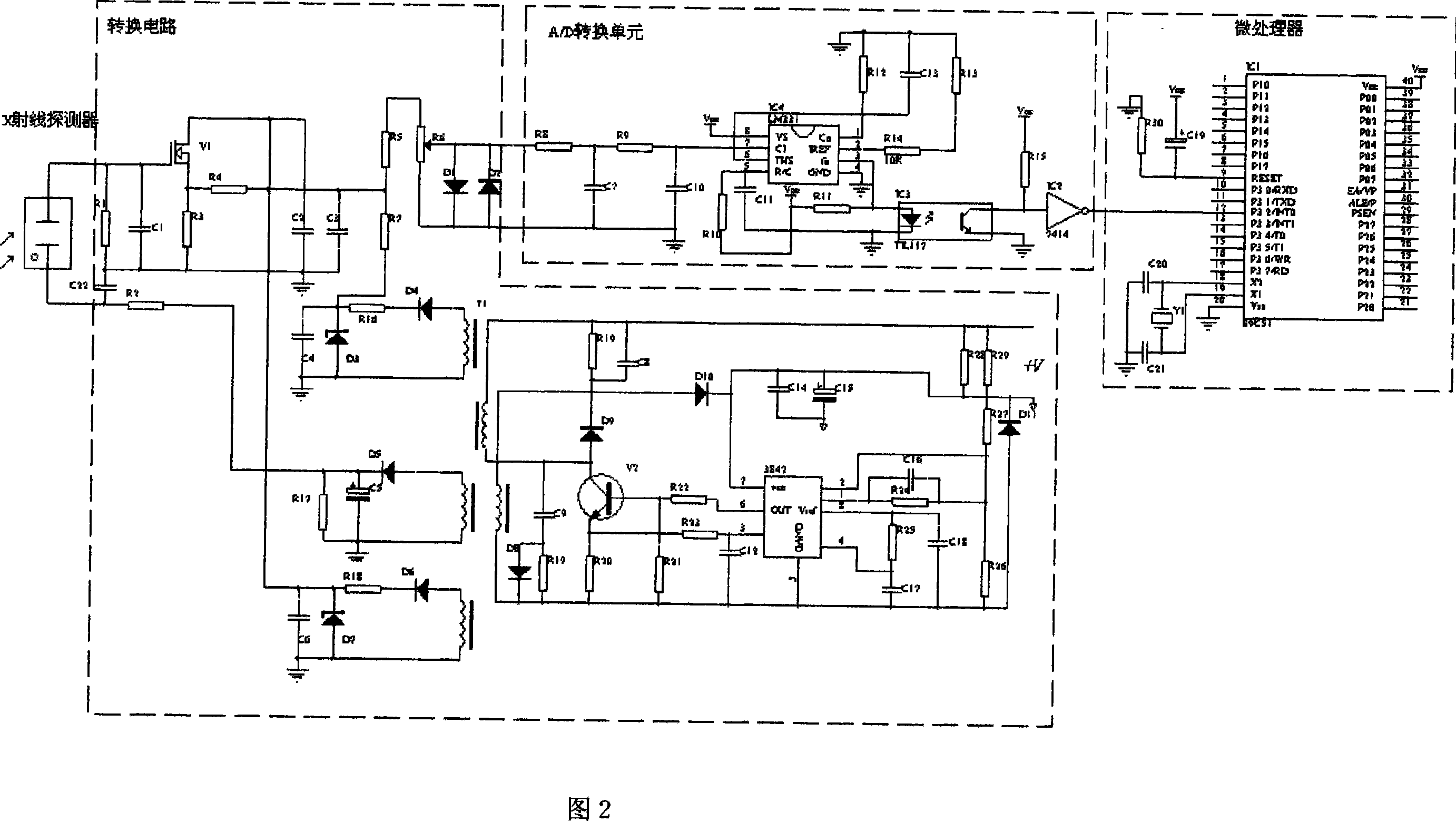

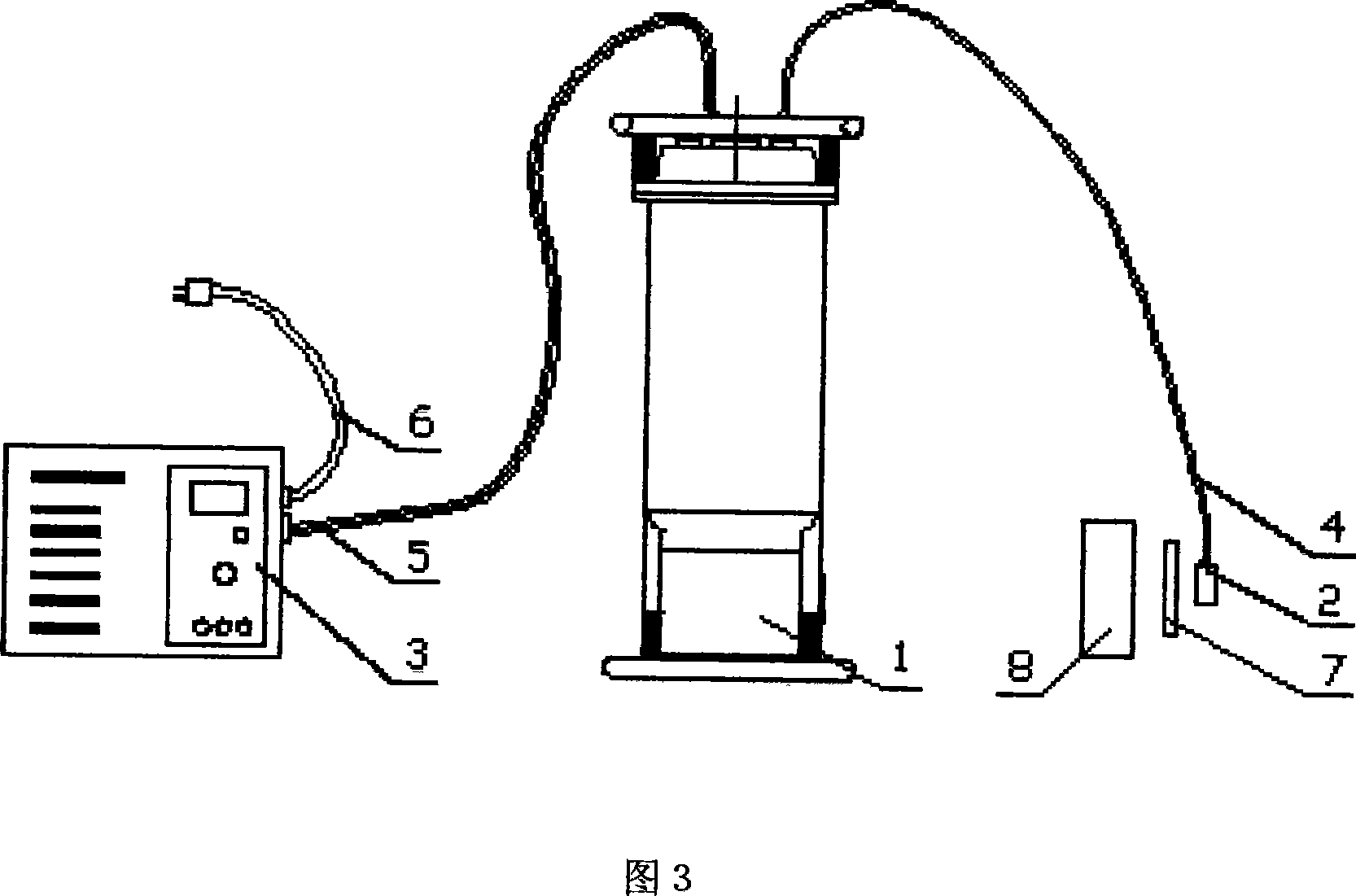

[0023] Embodiment 1 A connection structure between a portable X-ray flaw detector and a detection control device is illustrated in conjunction with accompanying drawing 3: the principle of radiation dose detection and control is shown in Figure 1, the circuit of the X-ray detection device is shown in Figure 2, and the X-ray detector adopts the product model GL1221, the signal of the X-ray detector is connected to the conversion circuit, and they are installed together to form a single component, that is, the X-ray dose detection device 2, and the X-ray dose detection device 2 is connected to the X-ray flaw detector with the dose transmission cable 4 and the connection cable 5 The A / D circuit in the controller 3 is composed of commodity LM331 and peripheral components. The A / D circuit is connected to the commodity 89C51 microprocessor in the controller 3 of the X-ray flaw detector. Generator 1, the power supply cable 6 of X-ray flaw detector controller 3 is connected to the powe...

Embodiment 2

[0039] Embodiment 2 The connection structure between a mobile X-ray flaw detector and the detection control device is shown in Figure 4. The X-ray detector adopts the product model GL1221, and the signal of the X-ray detector is connected to the conversion circuit. They are installed together to form a single The components of X-ray dose detection device 5 are X-ray dose detection device 5, which is connected to the A / D circuit composed of commodity LM331 and peripheral components in the controller 4 of X-ray flaw detector with dose transmission cable 8, and the A / D circuit is connected to X-ray The product model 89C51 microprocessor in the controller 4 of the flaw detection machine, the signal output end of the microprocessor is connected to the display unit mounted on the control panel, and the signal output of the microprocessor controls the parameters of the X-ray flaw detector. The X-ray flaw detector controller 4 signal output end is connected to the anode high-voltage ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com