Method for producing semiconductor structure of thin-film transistor and planar display device

A technology of thin-film transistors and manufacturing methods, applied in semiconductor/solid-state device manufacturing, optics, instruments, etc., can solve the problems of expensive photomasks, high cost, and increased manufacturing time, so as to reduce the cost of photomasks and reduce Production cost, effect of reducing the number of photomasks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The invention effectively reduces the number of photomasks needed in the process of manufacturing the thin film transistor of the liquid crystal display, and can effectively reduce the manufacturing cost of the liquid crystal display. The following will clearly illustrate the spirit of the present invention with illustrations and detailed descriptions. After those skilled in the art understand the preferred embodiments of the present invention, they can be changed and modified by the techniques taught in the present invention without departing from the present invention. The spirit and scope of the invention.

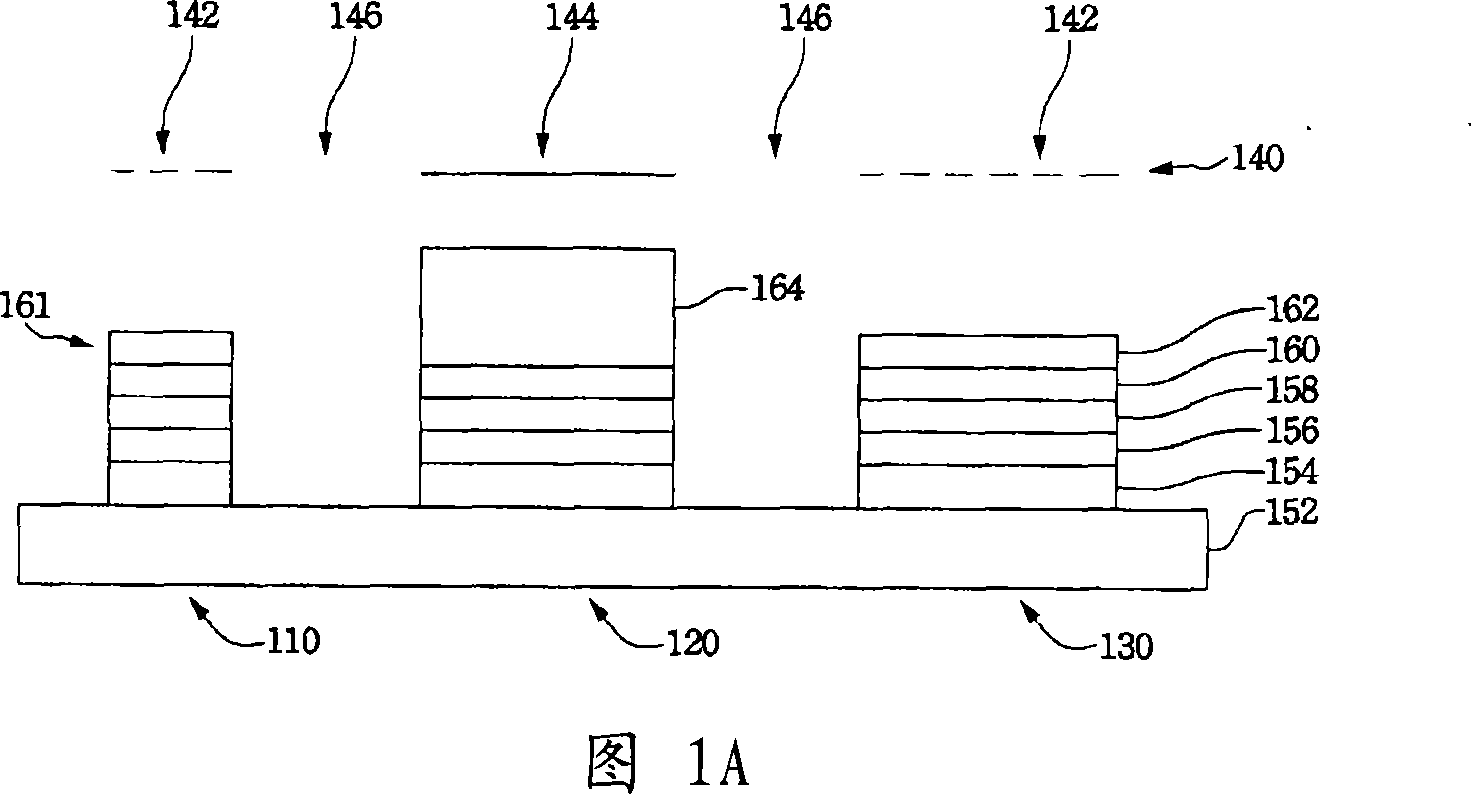

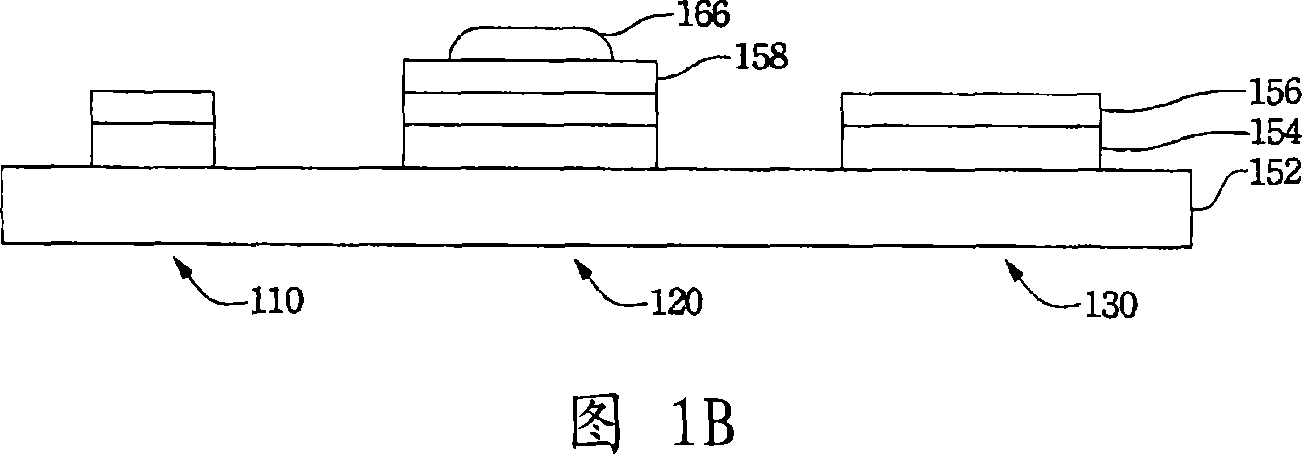

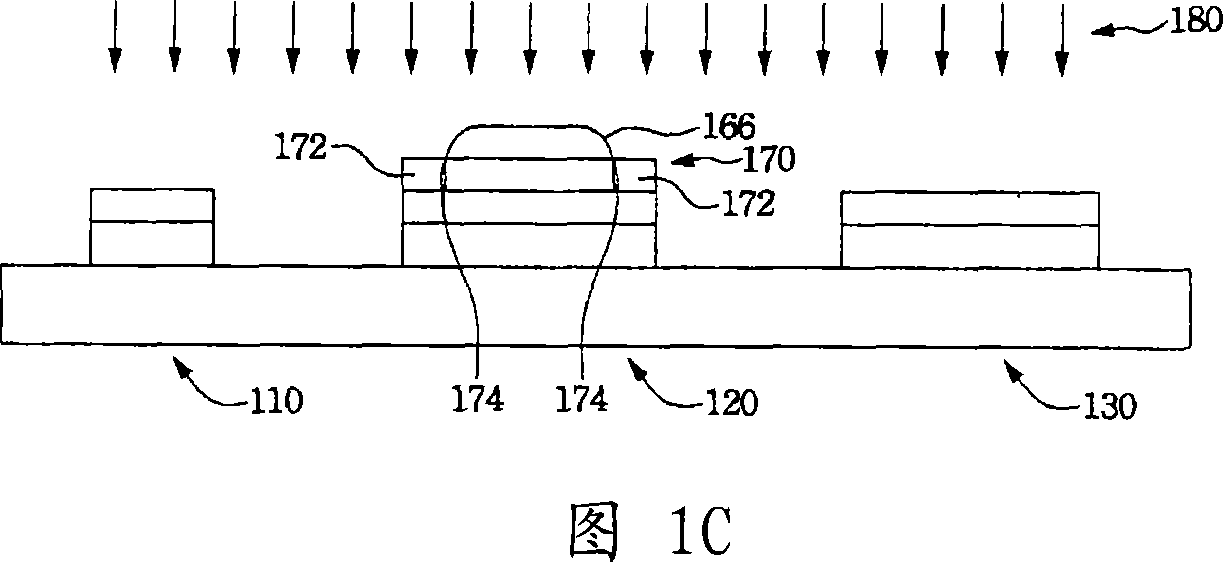

[0052] 1A-1H are schematic diagrams illustrating the fabrication process of a preferred embodiment of the fabrication method of the thin film transistor structure of the present invention. Referring first to FIG. 1A , a substrate 152 is provided, and then a conductive layer 154 , a dielectric layer 156 , a channel layer 158 , a passivation layer 160 and a photore...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com