Cross-linkable fluoroelastomer, its composition and cross-linked rubber molded product

A technology of fluoroelastomer and cross-linked rubber, which is applied in the field of fluoroelastomers, can solve problems such as insufficient production efficiency, impossibility of durable use, and failure to achieve mold release properties, and achieve excellent mold release properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

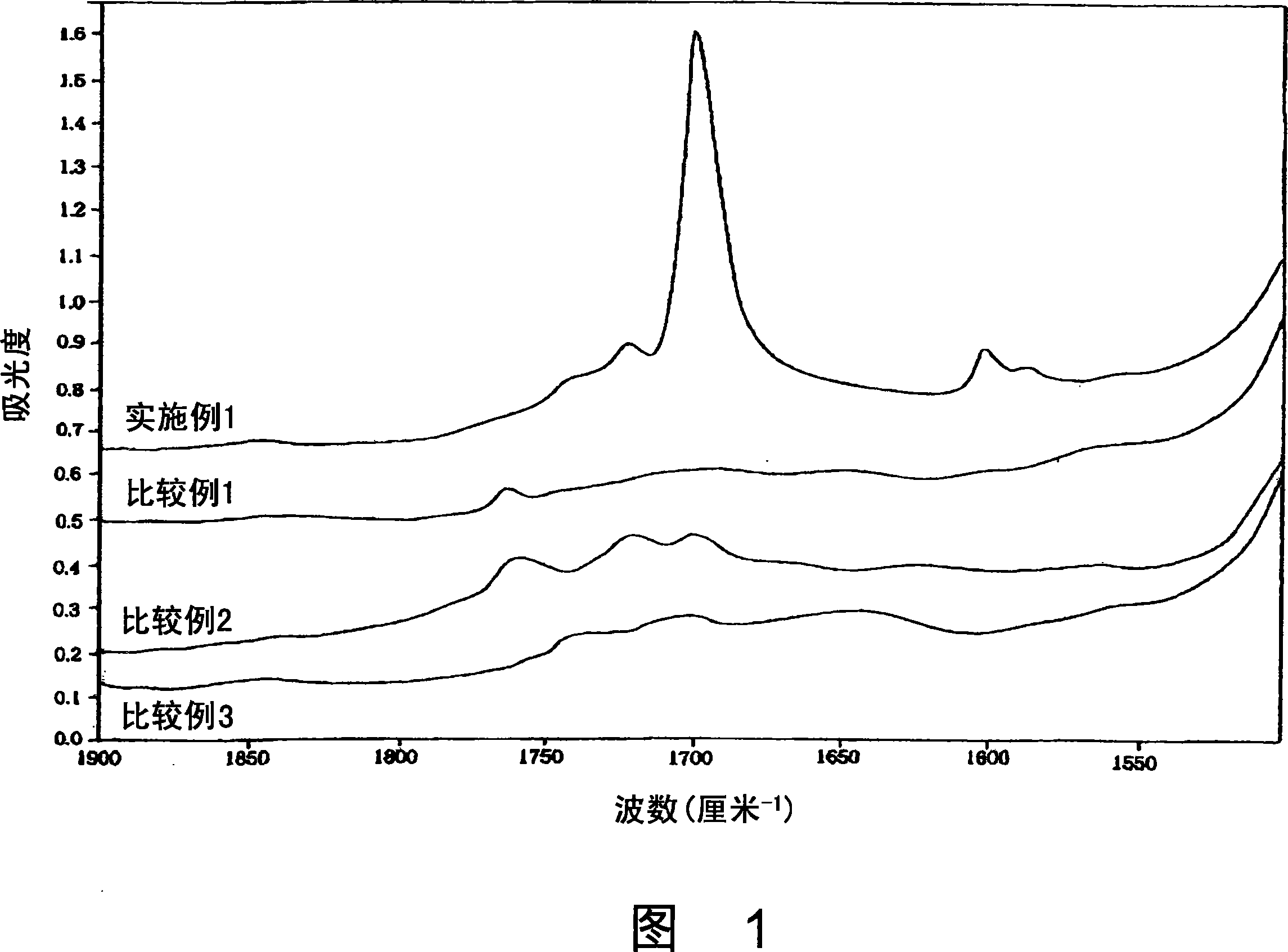

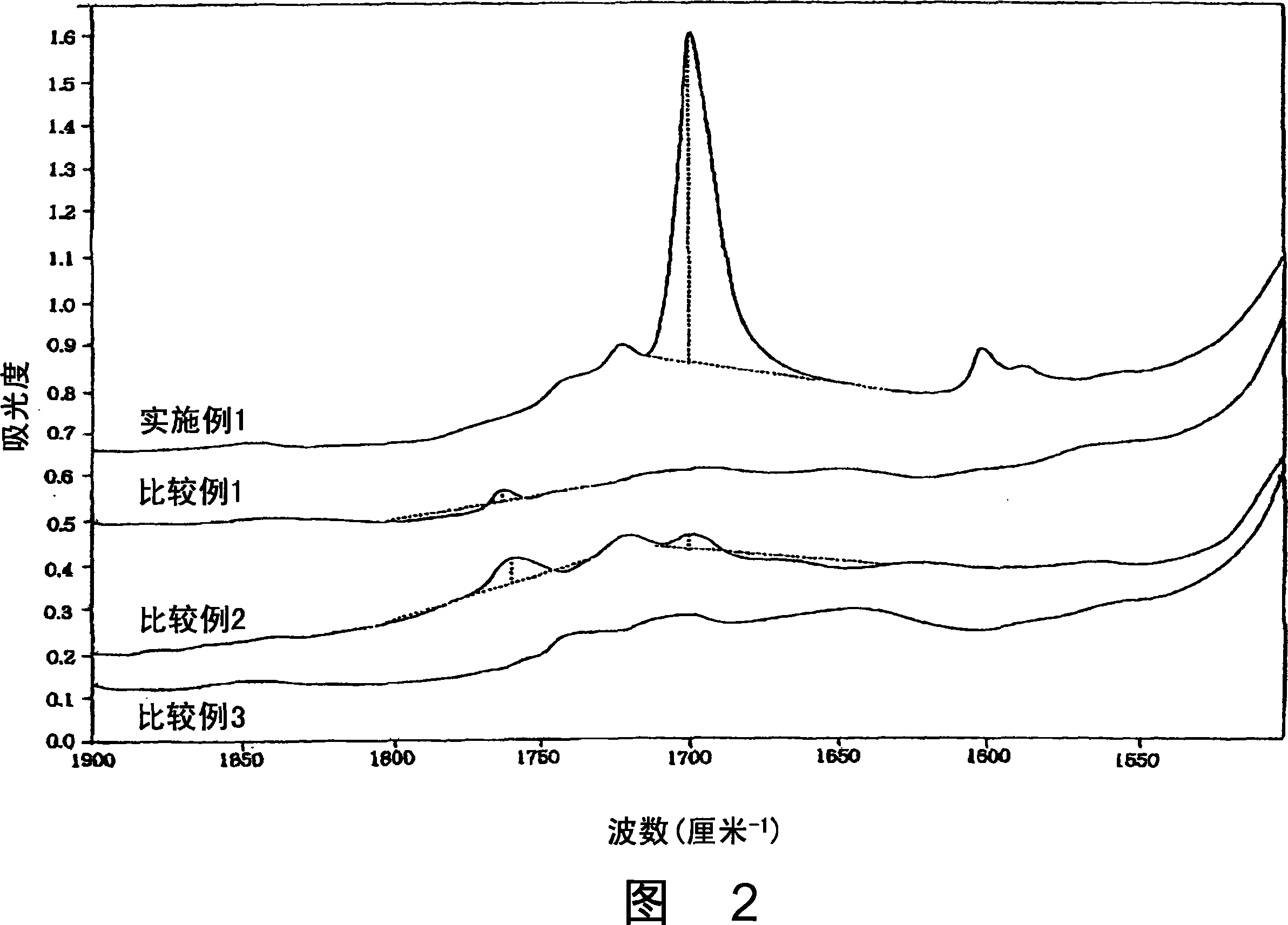

[0071] Add 1 part of dicumene peroxide (Percumyl D, manufactured by NOF CORPORATION) to 100 parts of TFE / P copolymer (copolymer composition: TFE / P=56 / 44 (mol%), Mooney viscosity: 105), so that the half-life temperature for 1 minute: 175.2°C), and then mixed using a twin-roller mill, the mixture was placed in a single-screw extruder set at 300°C, and extruded with a residence time of 2 minutes to obtain Crosslinkable fluoroelastomer. The infrared absorption spectrum of the prepared cross-linkable fluoroelastomer is shown in Fig. 1 .

Embodiment 2 and 3

[0073] In the same manner as in Example 1, the treatment was carried out according to the conditions shown in Table 1, except that only the organic peroxide used was changed, thereby preparing a crosslinkable fluoroelastomer. In Example 2, tert-butylcumyl peroxide (Perbutyl C, produced by NOF CORPORATION, temperature at which the half-life is 1 minute: 173.3° C.) was used. In Example 3, 1,3-bis(tert-butylperisopropyl)benzene (Perbutyl P, produced by NOF CORPORATION, temperature at which the half-life is minutes: 175.4° C.) was used.

Embodiment 4 and 5

[0075] In the same manner as in Example 1, the treatment was carried out using the conditions shown in Table 1, the difference being that the organic peroxide used and the heat treatment conditions were changed, so as to prepare a crosslinkable fluoroelastomer. In Example 5, di-tert-butyl peroxide (Perbutyl D, produced by NOF CORPORATION, temperature at which the half-life is 1 minute: 185.9° C.) was used.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com