Aeolian sandy soil modifying agent and preparing method thereof

A technology of aeolian soil and modifier, applied in chemical instruments and methods, soil conditioning materials, organic fertilizers, etc., can solve the problem of high cost, and achieve the effects of increasing content, improving granule structure, and improving use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

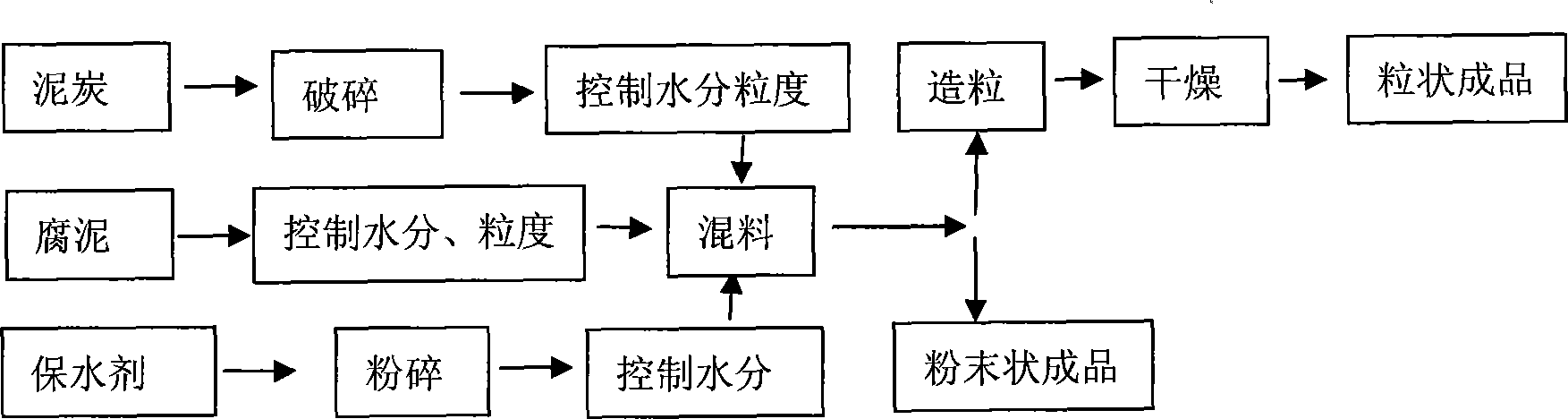

Method used

Image

Examples

Embodiment approach 1

[0025] Select 100g of Jiaohe peat (organic matter 57%, water content 25%) in Jilin Province, crush and screen the particle size below 6mm, and use the water-retaining agent biodegradable superabsorbent resin developed by Northeast Normal University (pH7.5, moisture 5%, particle size 0.2mm) ) 1g, pulverize and sieve particle size below 1mm, after mixing evenly, add in 1000g (after air-drying, water content 30%) in the wind-blown sandy soil of western Jilin Province, as plow layer, sow Chinese cabbage, the result after 40 days shows: with contrast 100% wind-blown sandy soil In comparison, the bulk density of the soil decreased by nearly 313%, the content of organic matter increased by nearly 789%, the content of humic acid increased by 110%, the height of cabbage increased by 154%, and the dry weight increased by 359%.

Embodiment approach 2

[0027] Jilin Province Shuangyang peat (58% organic matter, water content 30%) 80g, crushed and screened particle size below 6mm, sapropel (water content 44%, organic matter content 3.5%) 320g, crushed and screened particle size below 4mm, and the biological quality assurance developed by Northeast Normal University Water agent (pH7.5, moisture 5%, particle size 0.2mm) 1.5g, crushed and screened particle size below 1mm, after mixing evenly, add to 1000g of wind-sand soil in the west of Jilin Province (after air-dried, water content 30%), as the cultivation layer, sow For cabbage, the results after 40 days showed that compared with the control 100% aeolian soil, the bulk density of the soil decreased by nearly 20%, the content of organic matter increased by nearly 600%, the content of humic acid increased by 119%, the height of cabbage increased by 250%, and the dry weight increased by 455%.

Embodiment approach 3

[0029] Select 120g of Shuangyang peat (58% organic matter, 30% water content) in Jilin Province, crushed and screened with a particle size of 2mm or less, 280g of sapropel (44% water content, 3.5% organic matter content), crushed and screened with a particle size of 2 mm or less, and the water-retaining product developed by Northeast Normal University. 1g of biodegradable superabsorbent resin (pH7.5, moisture 5%, particle size 0.2mm), after mixing evenly, granulate for 5 minutes while spraying water, dry for 20 minutes, and cool, the specification is particle size 1 ~ 3mm , Strength 15-30N, moisture 5-10%. Add it to 1000g of wind-blown sandy soil in the west of Jilin Province (after air drying, water content 30%), then plant Chinese cabbage, the results after 40 days show: compared with the control, the bulk density of the soil decreased by nearly 25%, the organic matter content increased by nearly 900%, and the humic acid content 154% increase, 195% increase in cabbage height...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com