Composite mould for fusion-casting refractory material and manufacturing method thereof

A technology of melting and casting refractory materials and composite molds, which is applied in the field of refractory materials, can solve the problems of limited temperature resistance and inability to produce with melting and casting refractory materials, and achieve the effects of not easy to fall off, easy to clean, and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

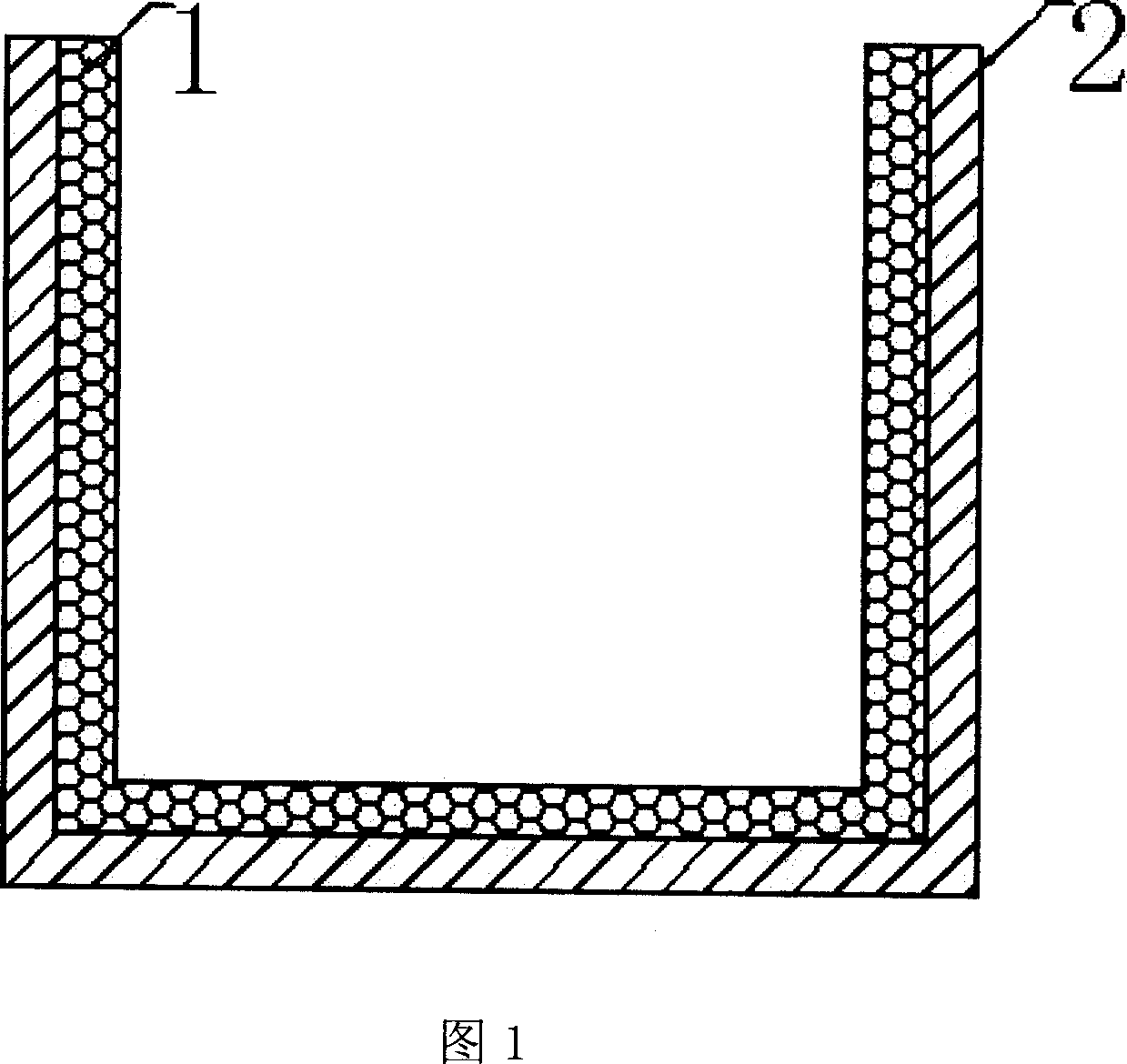

[0015] Embodiment 1, a composite mold for melting and casting refractory materials, with the high-temperature alumina of particle size 200 mesh as raw material (component content is Al 2 o 3 98%, SiO 2 0.9%, Na 2 (00.8%), plus the water glass of its weight percentage 11% as binding agent, brush on SiO after mixing uniformly 2 The side of the mold matrix 2 that is in contact with the high-temperature melt of the cast refractory material is baked and solidified at 200-300° C. to form a composite mold with a composite layer 1 . Composite layer thickness / substrate thickness=1 / 10. Composite layer chemical composition (percentage by weight) composition is shown in Table 1 (the rest are impurities):

[0016] Table I

[0017] project

Embodiment 2

[0018] Embodiment 2, a composite mold for melting and casting refractories, with 80% by weight of industrial alumina, 13% of soda ash and 7% of quartz sand as raw materials, the fineness of raw materials is 0.5-3mm, and 11% by weight of Water glass, mixed evenly and bonded to SiO 2 The side of the mold base 2 that is in contact with the high-temperature melt of the cast refractory material is baked and solidified at 200-300° C. to form a composite mold with a composite layer 1 . Composite layer thickness / substrate thickness=1 / 1. The chemical composition (percentage by weight) of industrial alumina is shown in Table 2:

[0019] Table II

[0020] project

Al 2 o 3

SiO 2

Na 2 o

Industrial alumina (%)

98.5

0.5

1.0

[0021] The chemical composition (percentage by weight) of the composite layer is shown in Table 3 (the rest are impurities):

[0022] Table three

[0023] project

Embodiment 3

[0024] Embodiment 3, a composite mold for melting and casting refractories, with high-purity alumina as raw material (alumina content of 99.5% by weight), fineness of 300 mesh, plus 5% by weight of FNJCY-121 type phenolic resin As a binder, mix well and brush on SiO2 2 The side of the mold matrix 2 that contacts the high-temperature melt of the cast refractory material is solidified at room temperature to form a composite mold with a composite layer 1 . Composite layer thickness / substrate thickness=1 / 10. The chemical composition (percentage by weight) of the composite layer is shown in Table 4 (the rest are impurities):

[0025] Table four:

[0026] project

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com