Environmental protection biological diesel and preparation method thereof

A biodiesel, environmentally friendly technology, applied in the direction of biofuel, petroleum industry, liquid carbon-containing fuel, etc., can solve the problems of ecological environment pollution, impact on life, environment and physical health, and achieve the effect of reducing pollution and low damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

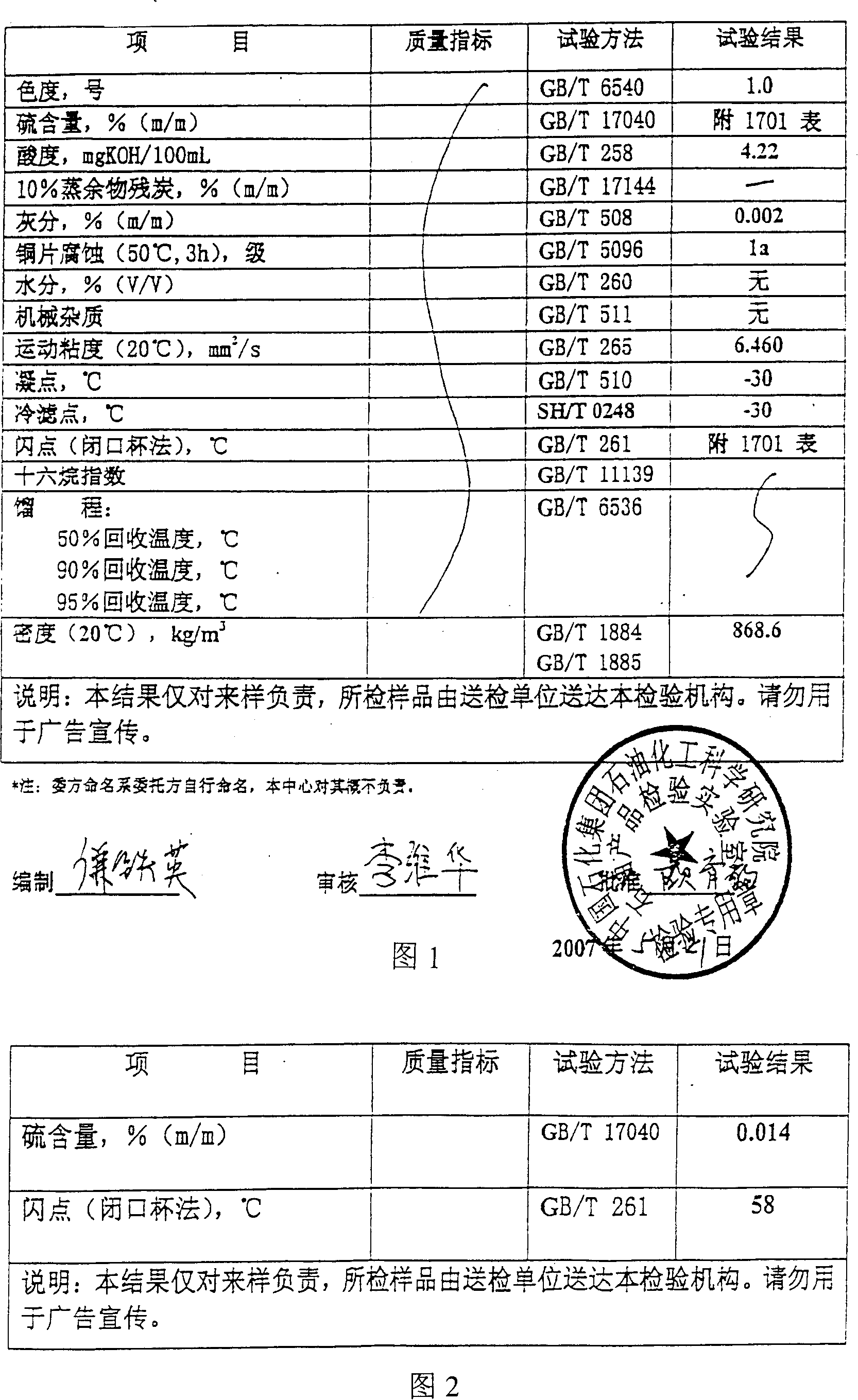

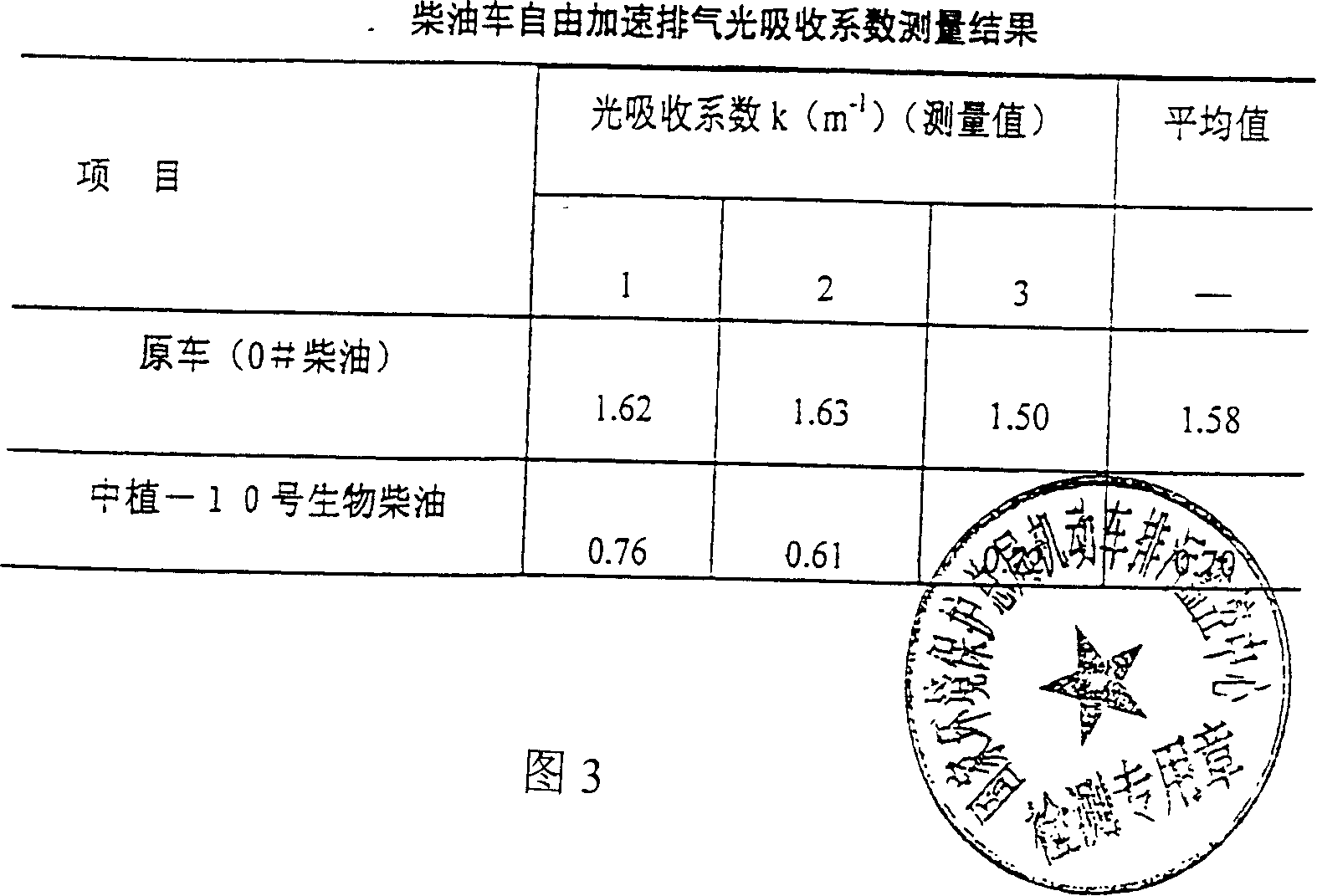

Image

Examples

Embodiment 1

[0017] Vegetable oil 20%, methanol 25%, ethanol 5%, kerosene 5%, No. 0 diesel oil 40%, additive 5%.

Embodiment 2

[0019] Vegetable oil 25%, methanol 25%, ethanol 5%, kerosene 5%, No. 0 diesel oil 35%, additive 5%.

Embodiment 3

[0021] Vegetable oil 30%, methanol 20%, ethanol 5%, kerosene 5%, No. 0 diesel oil 35%, additive 5%.

[0022] Choose one of the above three formulations and operate as follows.

[0023] First, heat 20% vegetable oil in No. 1 reactor—titanium catalytic reactor, stir and catalyze, then add 25% methanol into the kettle, continue heating and stirring, and then add 40% No. 0 diesel oil Continue heating and stirring in the kettle. When the temperature rises to 60-70°C, an intensified titanium-catalyzed reaction occurs in the kettle until the synthetic liquid is transparent. Then add 5% kerosene, 5% ethanol, and 5% additives into another titanium catalytic reaction kettle—No. 2 kettle in order to carry out titanium catalytic reaction, and stir for 5 minutes. Send the synthesis solution in the No. 1 tank to the cooling reactor, and after the temperature is rapidly lowered by 10-20°C, it is sent to the No. 3 reactor, the strontium catalytic hydrogenation tank, for stirring and catalysi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com