Method for determining angular separation between two laser bean in concave surface holographic grating production light path

A technology of holographic grating and laser beam, which is applied in the field of spectroscopy, can solve the problems of inapplicability, and achieve the effect of easy implementation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

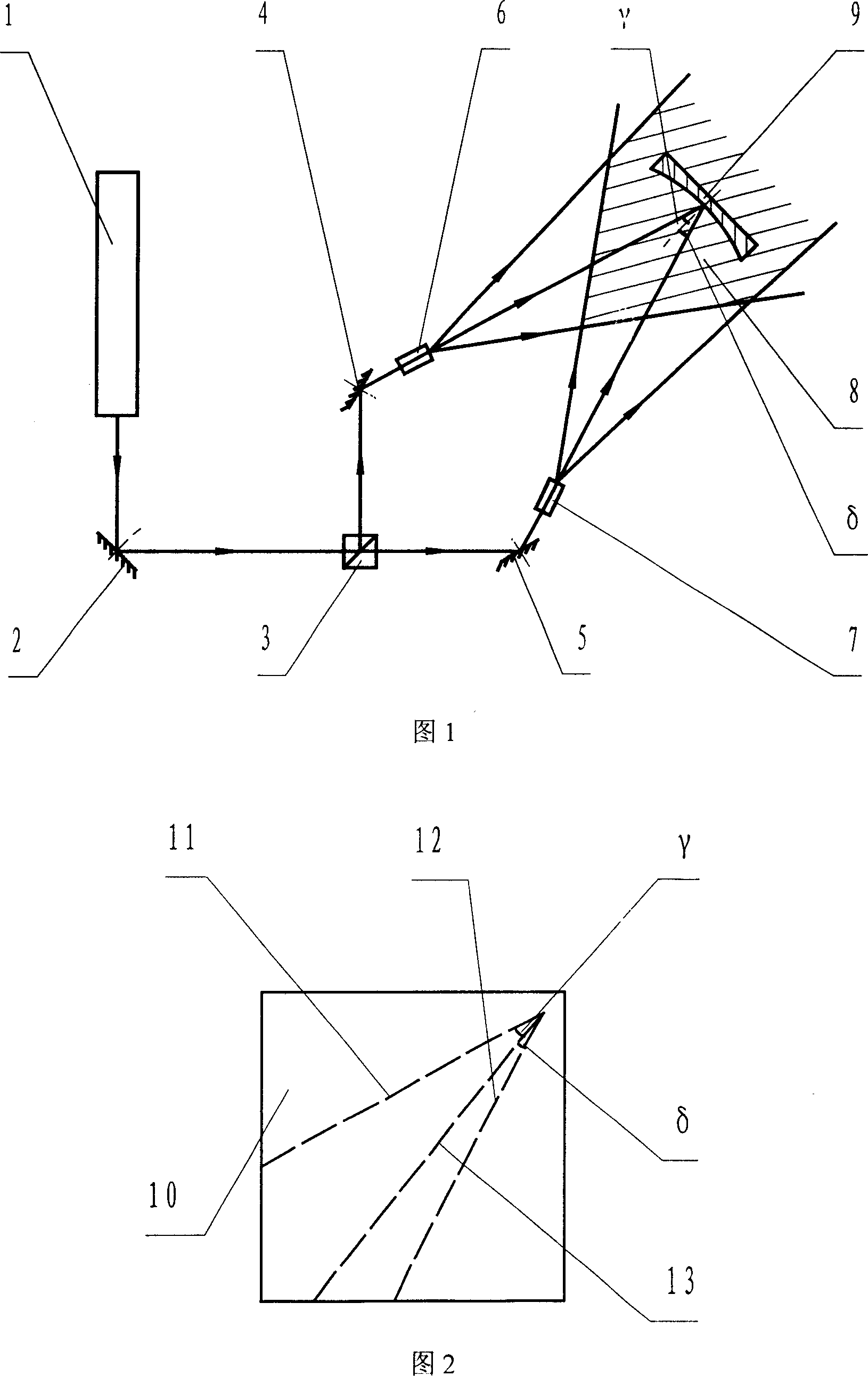

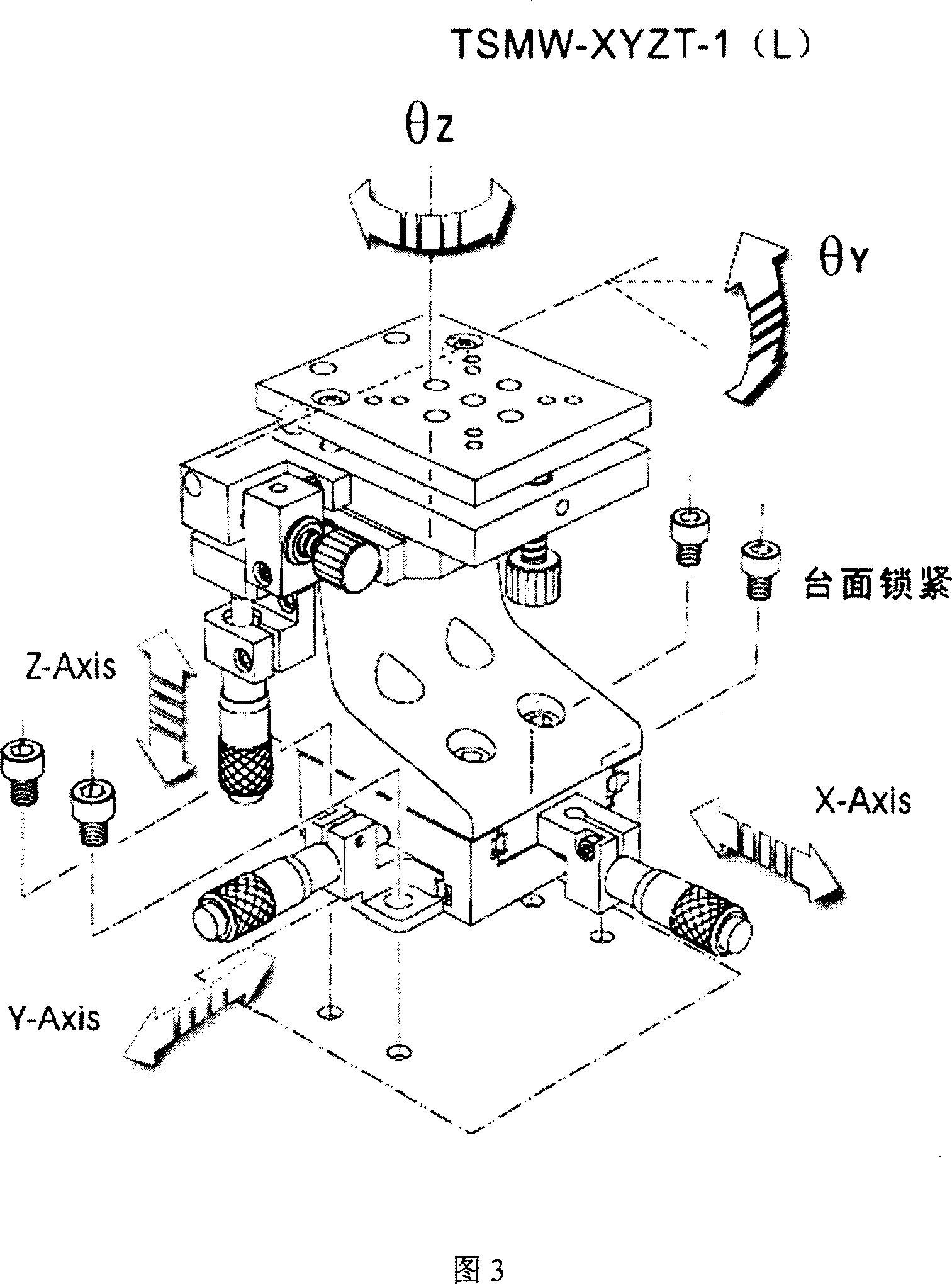

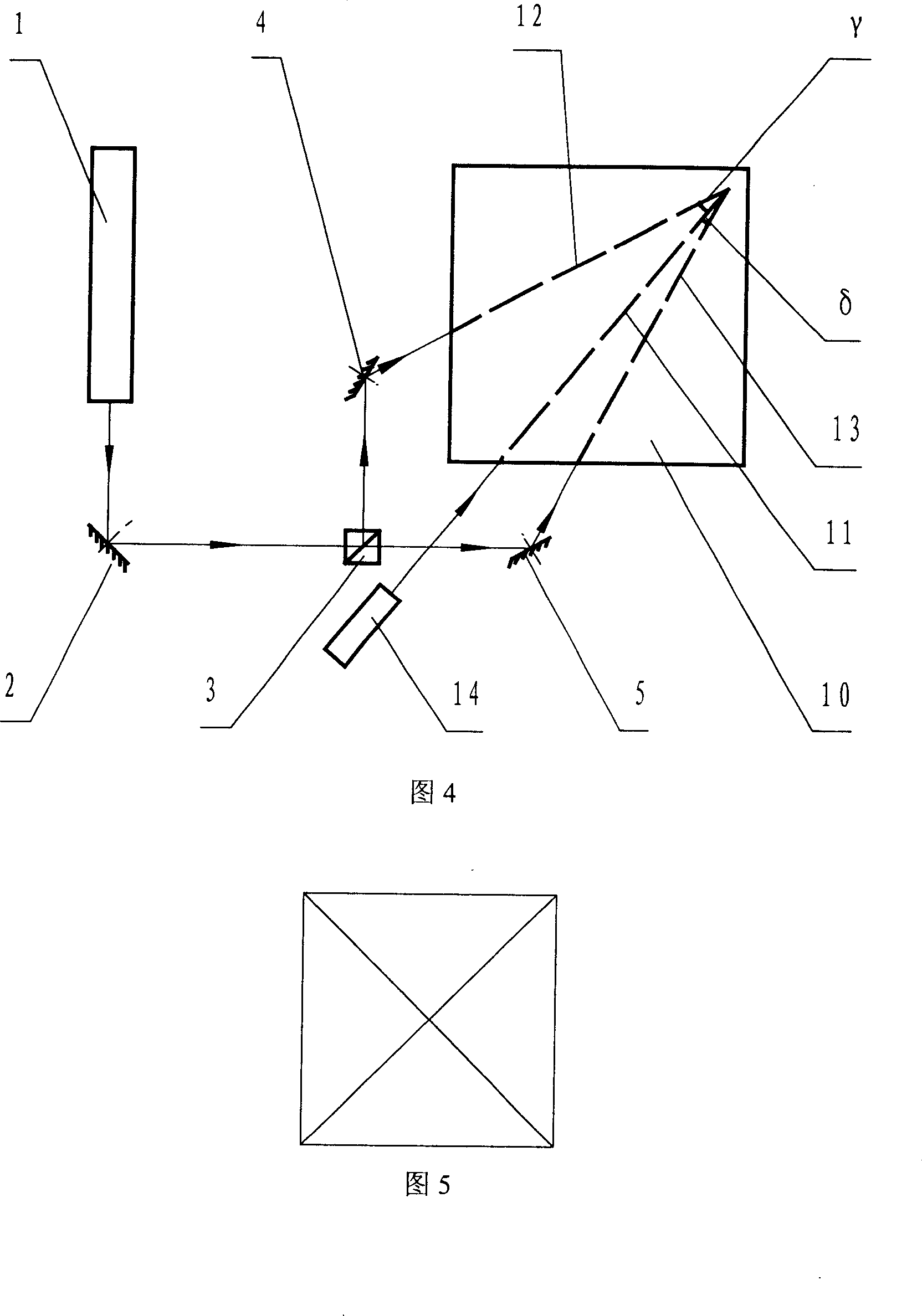

[0014] The present invention is implemented according to the established first, second, third and fourth four method steps. Light source 1 uses Kr + The laser has a wavelength of 413.1nm; the plane mirrors 2, 4 and 5 are aluminum-coated mirrors on glass substrates; the half-mirror half-mirror 3 is a double-glued glass prism; the pinhole filters 6 and 7 are composed of a microscope objective lens and a pinhole; The concave holographic grating blank 9 adopts K9 optical glass, and the photoresist coated on the K9 optical glass is Shipley 1805 type photoresist produced in Japan; the output wavelength of the He-Ne laser 14 is 632.8nm; It is a transparent plexiglass substrate; large flat

[0015] The angle lines 11, 12 and 13 on the plate are precisely inscribed using computer control.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com