Process for manufacturing high gain dual-linear polarization or dual-circle polarization waveguide array antennas

A dual-linear polarization and dual-circular polarization technology, which is applied to antenna unit combinations, antennas, electrical components and other directions with different polarization directions, can solve the problems of low equivalent surface efficiency, high cost, complex structure, etc. The effect of reducing the thickness of the antenna section, low processing cost, and high feeding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

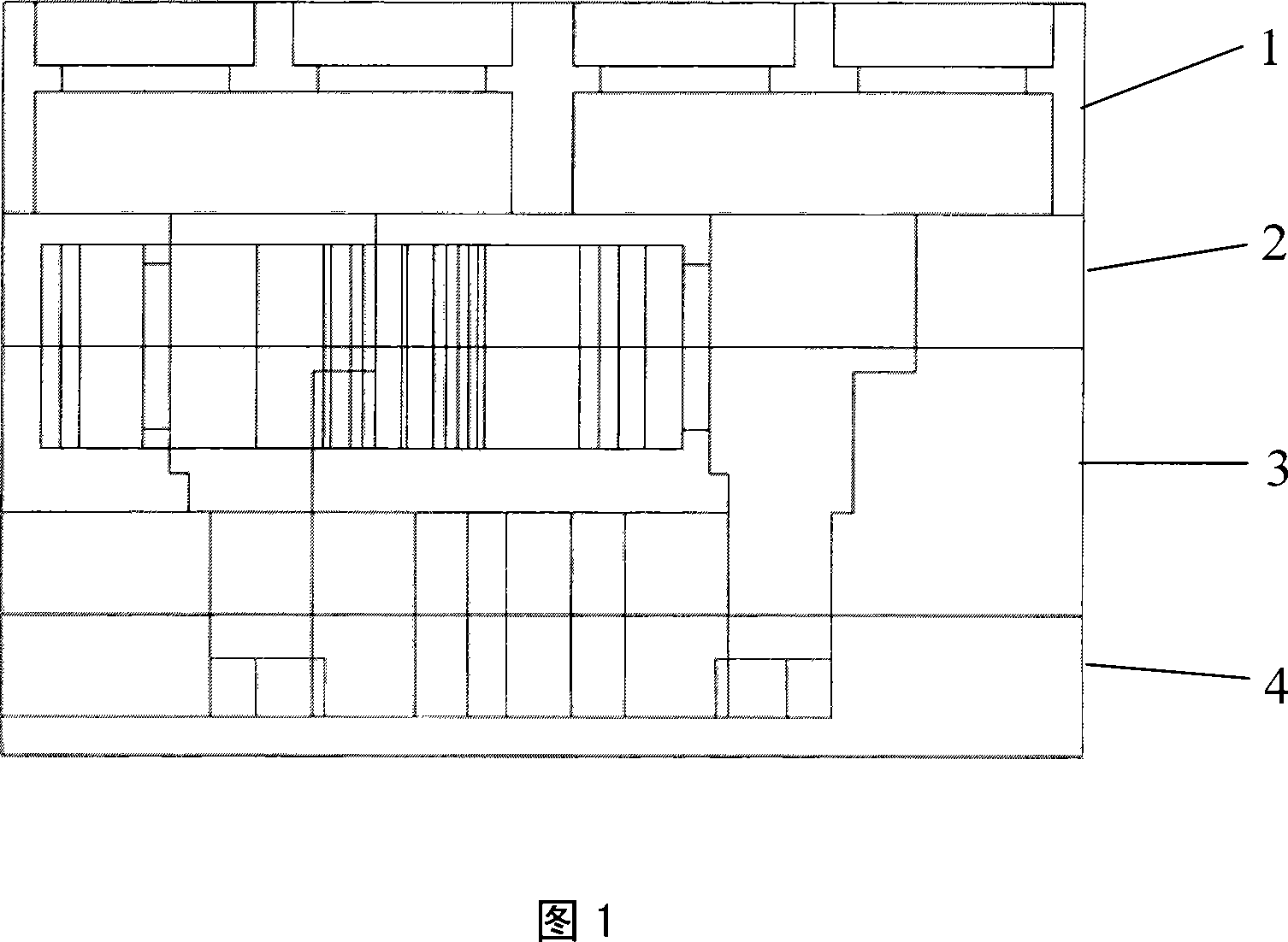

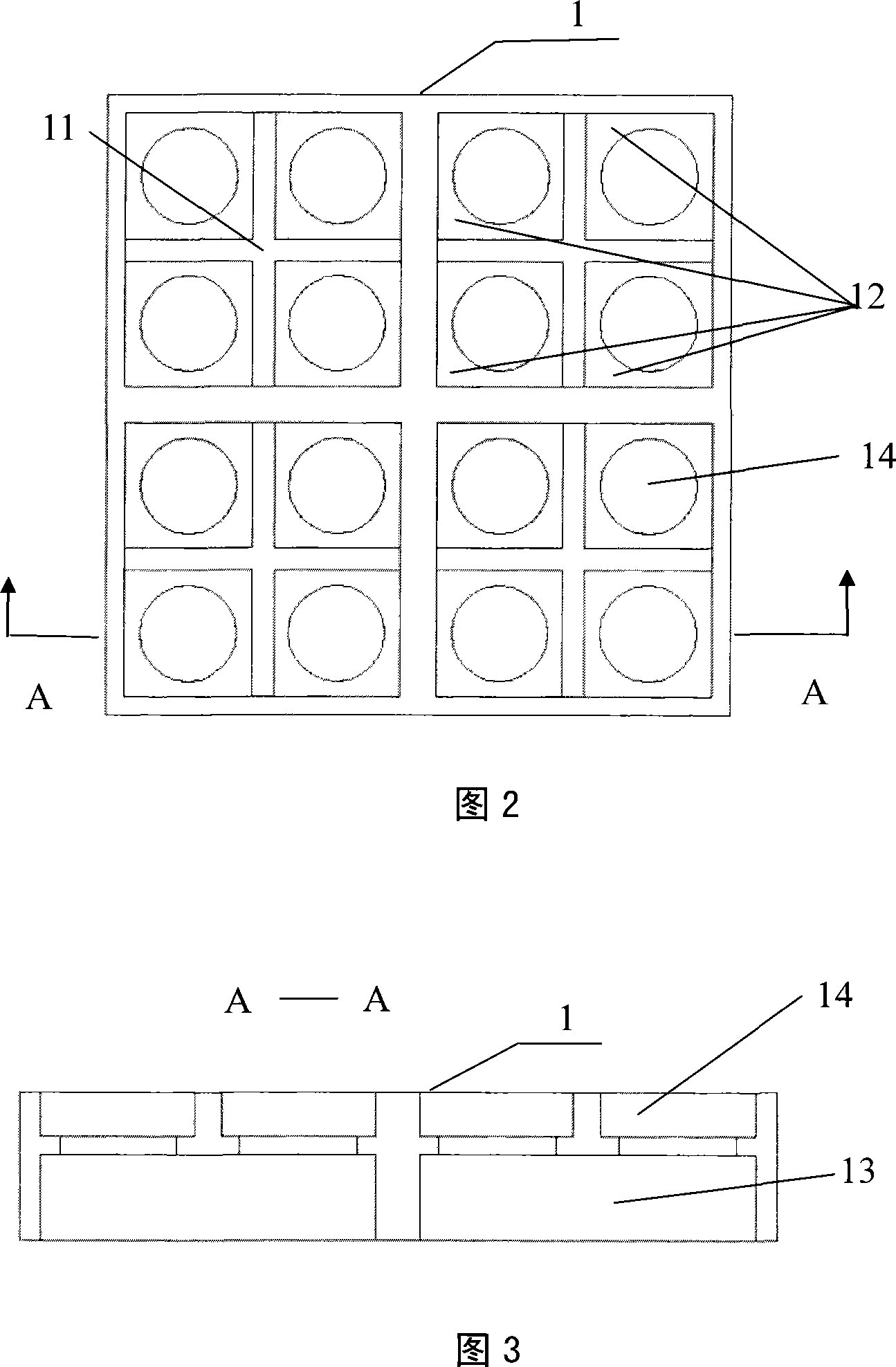

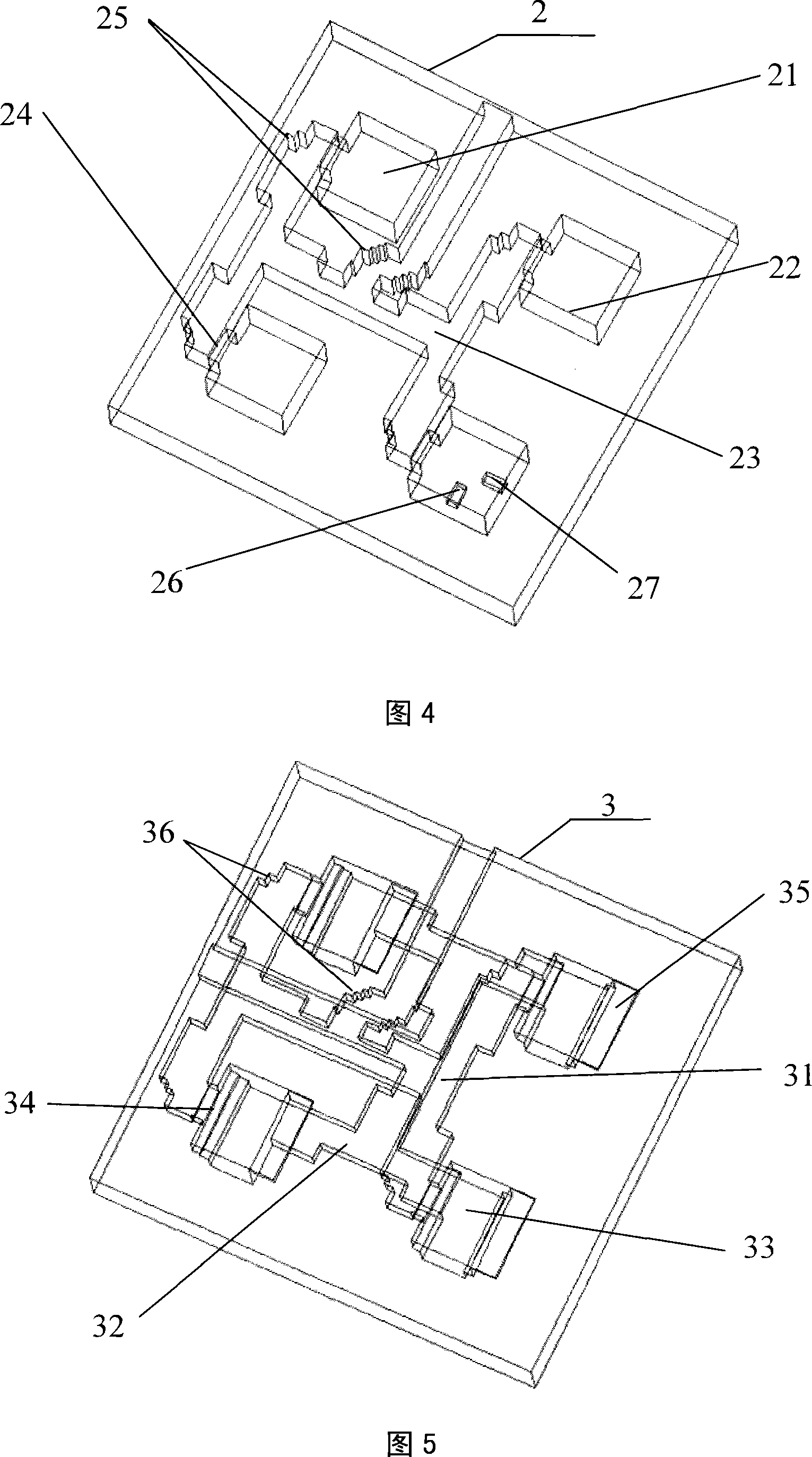

[0031] Referring to FIG. 1 to FIG. 6 , the embodiment of the present invention includes a radiation layer 1 , a horizontally polarized or circularly polarized feeding waveguide layer 2 , a vertically polarized feeding waveguide layer 3 , and a vertically polarized feeding waveguide cover plate 4 .

[0032] The present invention comprises steps:

[0033] ① The radiation layer 1 is designed according to the working frequency, and the radiation layer 1 is used to complete the resonance between the antenna and the space electromagnetic wave. The radiating layer 1 is designed with an array radiating interface of M×N radiating units 11 according to antenna gain requirements, where M or N is a natural number greater than 2. The more radiation units 11 in the array, the higher the gain. In an embodiment, 2×2 radiation units 11 are combined to form an array radiation interface, as shown in FIG. 2 . Each radiation unit 11 is made of aluminum alloy material with precision machining, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com