Process for manufacturing commutator

A manufacturing method and commutator technology, applied in the direction of commutator manufacturing, etc., can solve the problems of long production cycle, numerous production processes, large processing equipment and manpower, etc., achieve less equipment and required personnel, and good performance stability , The effect of reducing the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

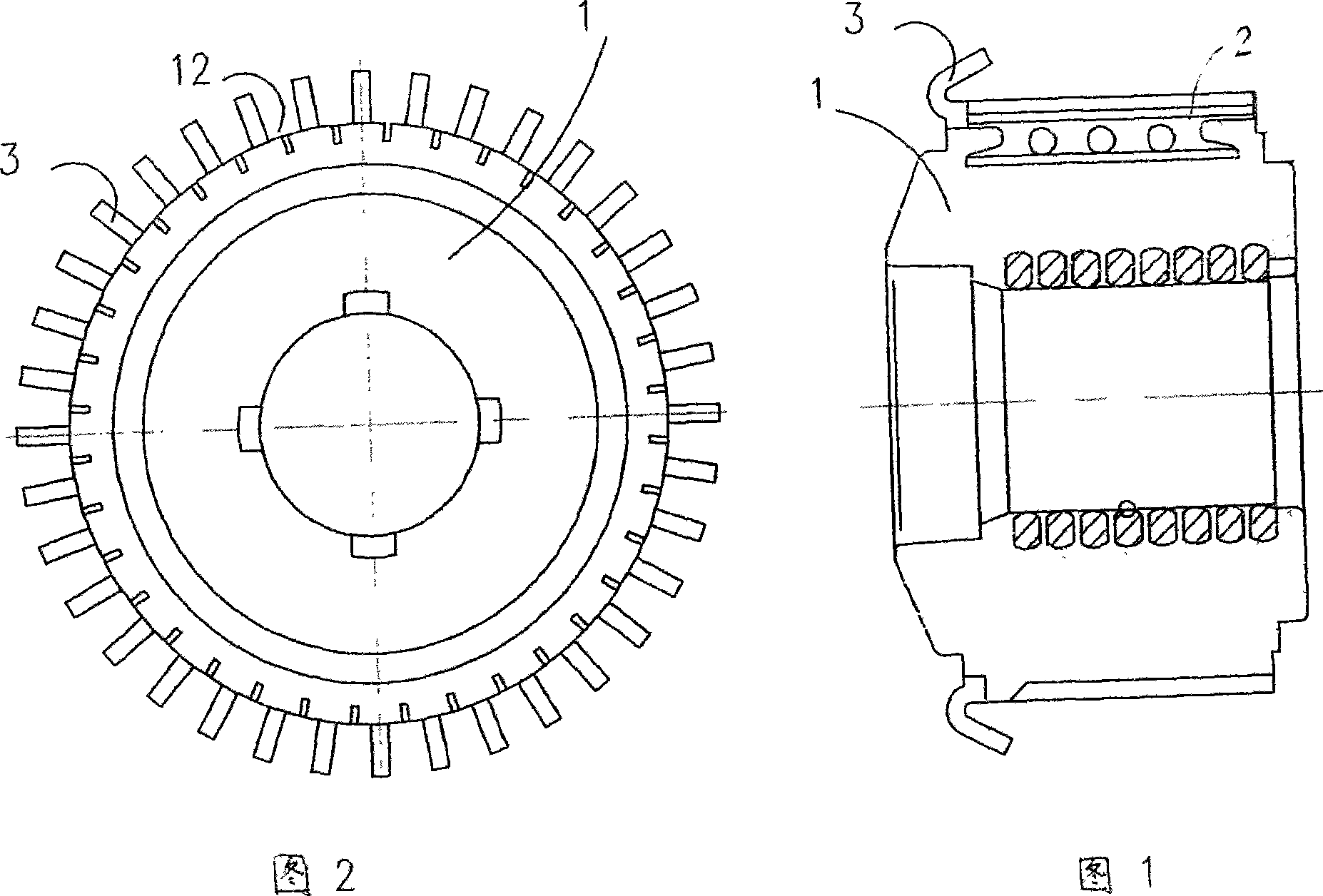

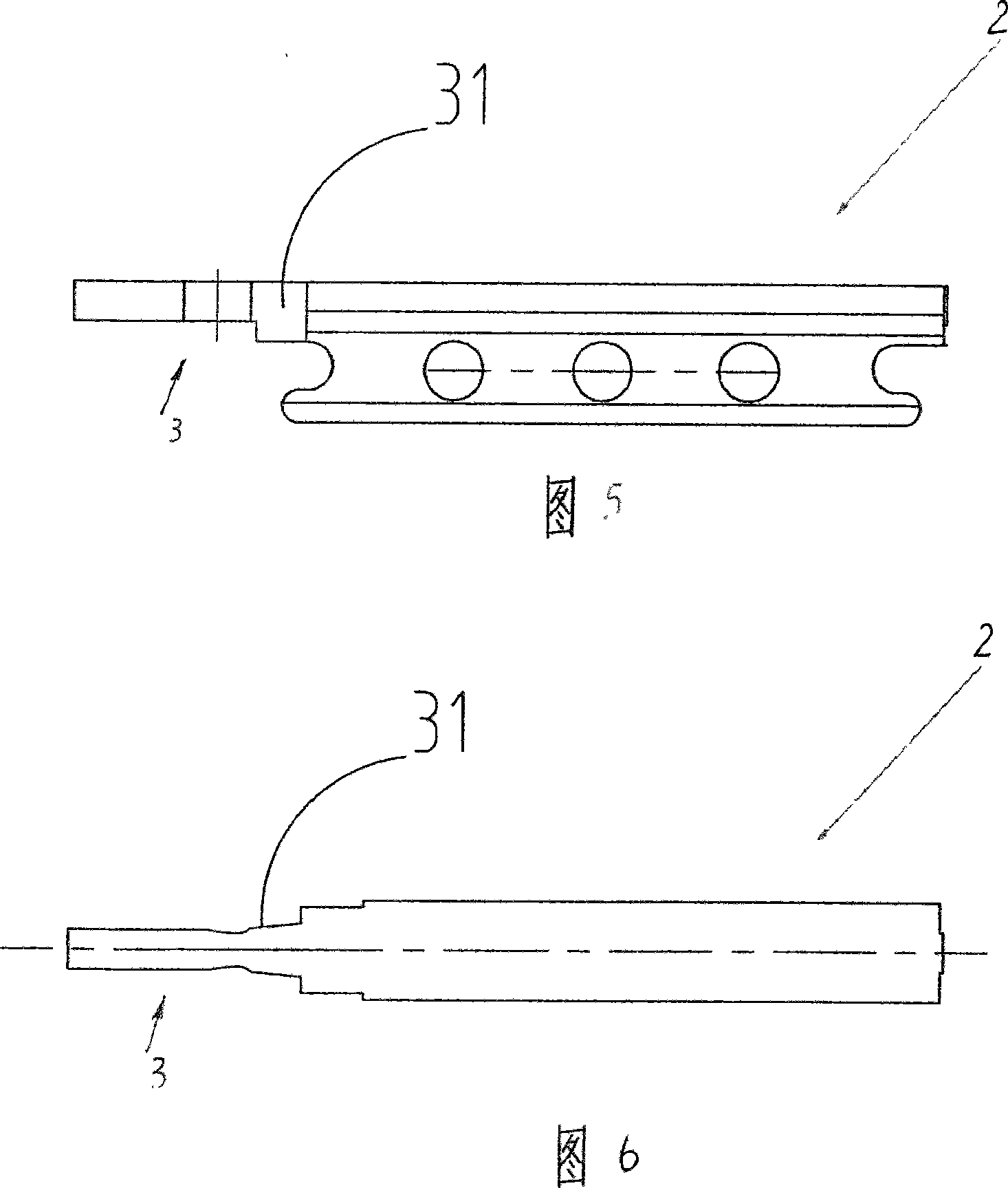

[0021] 1 to 4 show an embodiment of a manufacturing method of a commutator of the present invention. The commutator includes a commutator base 1 with a plurality of insulating grooves 12 evenly distributed in the circumferential direction, and a commutator segment 2 is placed in the insulating groove 12 of the commutator base; one end of the commutator segment 2 is provided with a hook Pin 3, as shown in Figure 1.

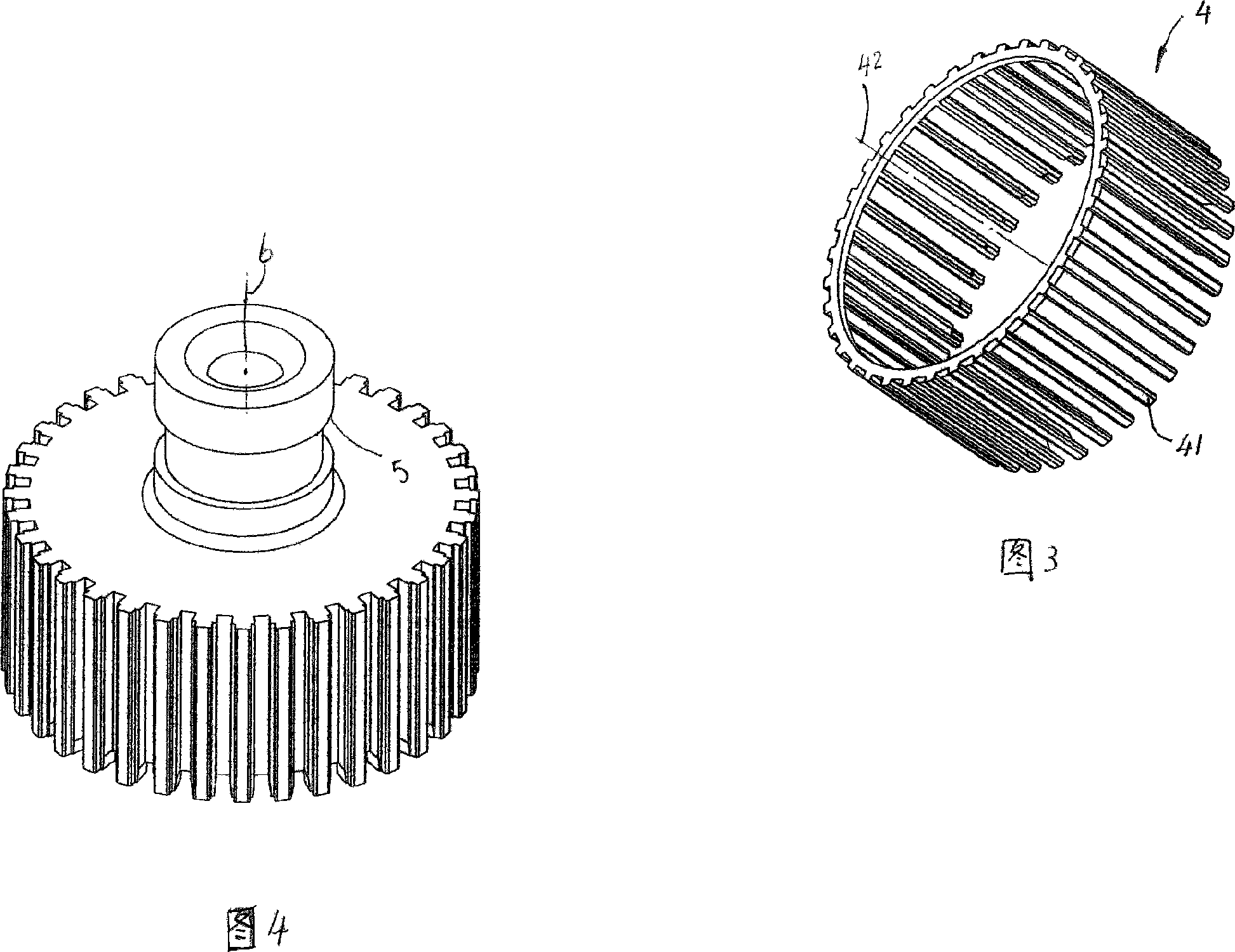

[0022] The commutator base 1 is made of engineering plastics, and the insulating groove 12 is injection-molded by a positioning shell 4, as shown in FIG. 3 . The positioning housing is configured with the outer diameter of the commutator base 1 .

[0023] Preferably, the positioning shell 4 is made of nylon; nylon material has strong mechanical toughness and high heat resistance, and its dimensional stability is better when the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com