Space interference-resistant arrangement for multiple hanging points crane hoisting wire rope

A technology for hoisting wire ropes and cranes, which is applied in the direction of load hanging components, transportation and packaging, etc. It can solve the problems of wire ropes, wire ropes and main girders interfering with each other, the number of hoisting mechanisms and winding systems is small, and the lifting of super heavy weights cannot be completed. , to achieve the effects of light weight, simple mechanism layout and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

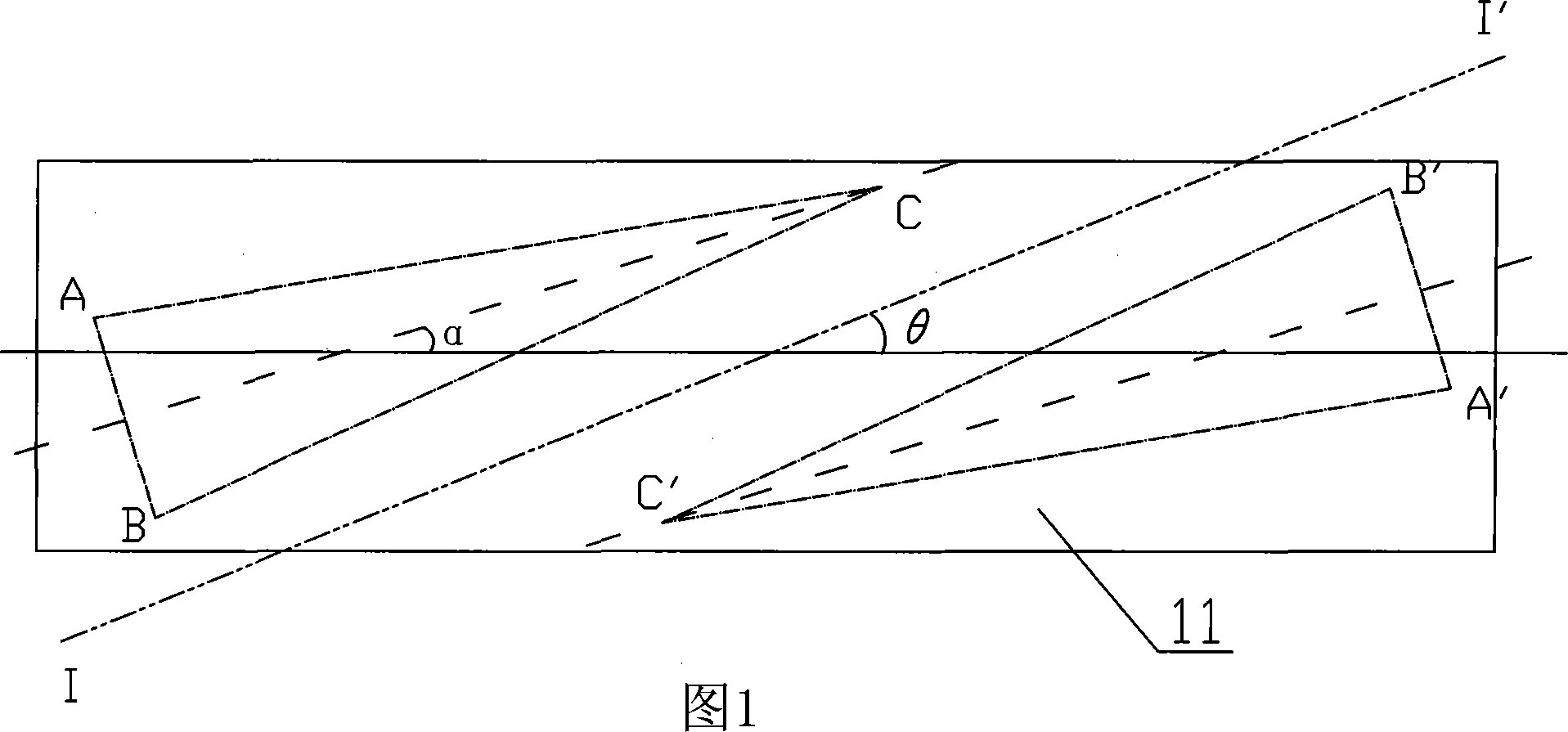

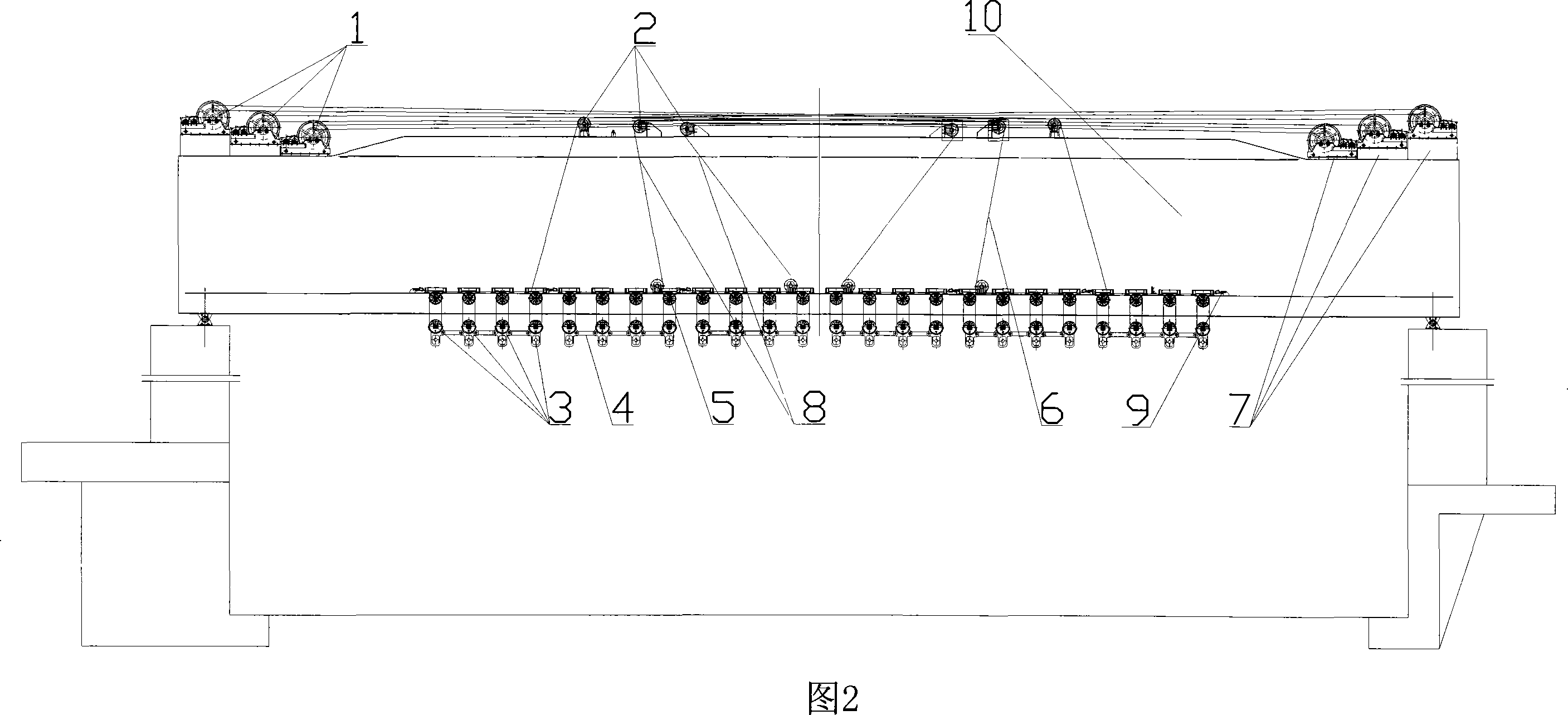

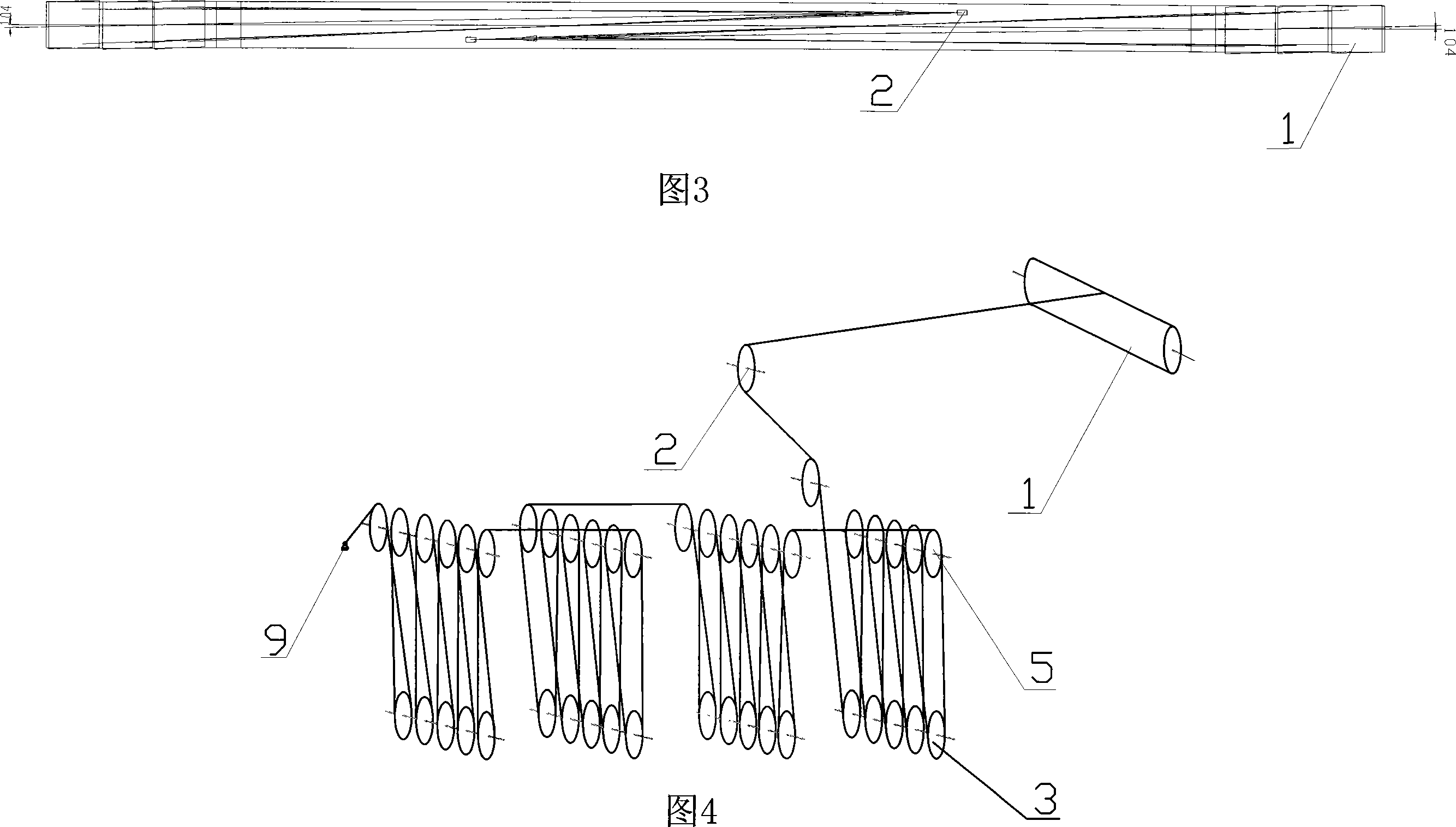

[0023] As shown in Figures 1 to 4, the anti-interference arrangement of the hoisting wire rope space of the multi-suspension crane is applied to the multi-suspension crane for super-heavy structures such as drilling platforms. The crane is usually used for lifting super large loads. The height of the main girder is relatively large, while the width of the web of the main girder is small. It usually consists of multiple sets of hoisting systems. Each hoisting system includes hoisting machine 1, guide pulley 2, The movable pulley block 3, the connecting rod between the movable pulley blocks 4, the fixed pulley block 5, the steel wire rope 6, the hoist support 7, etc. Usually, each hoisting system contains 4 movable pulley blocks, and each movable pulley block controls 1 lifting point. The winch 1 includes components such as a reel (including a wire rope pressure plate), a reducer, a brake, an open gear, a coupling, a floating shaft, that is, a complete set of drive mechanisms fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com