Wind direction-changing and temperature difference drying device for grain

A forward and reverse, grain technology, applied in the direction of drying solid materials, local stirring dryer, static material dryer, etc., can solve the problems of poor quality of dry grain, high investment cost, poor drying effect, etc., to protect the environment and save money. energy, pollution reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

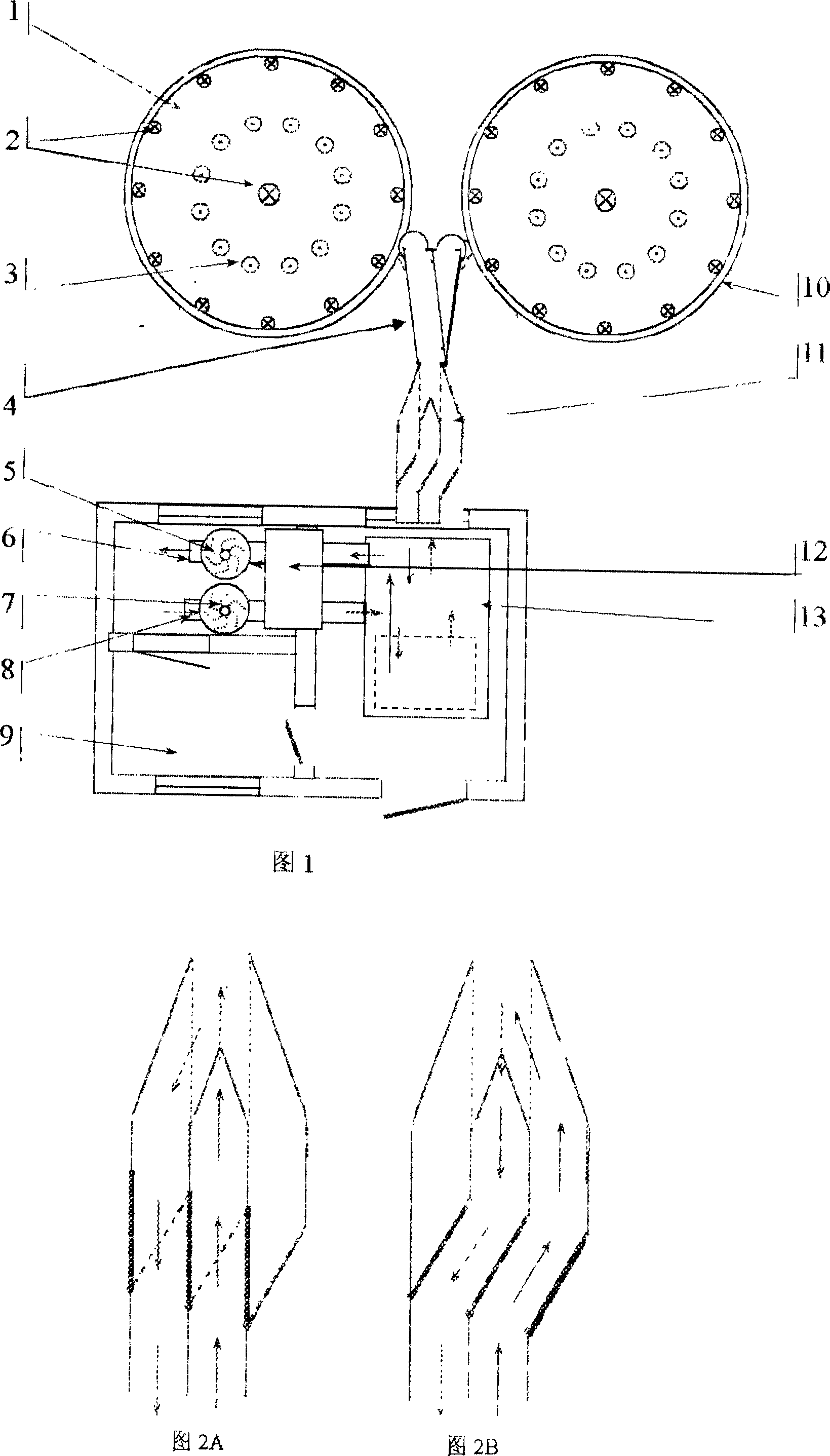

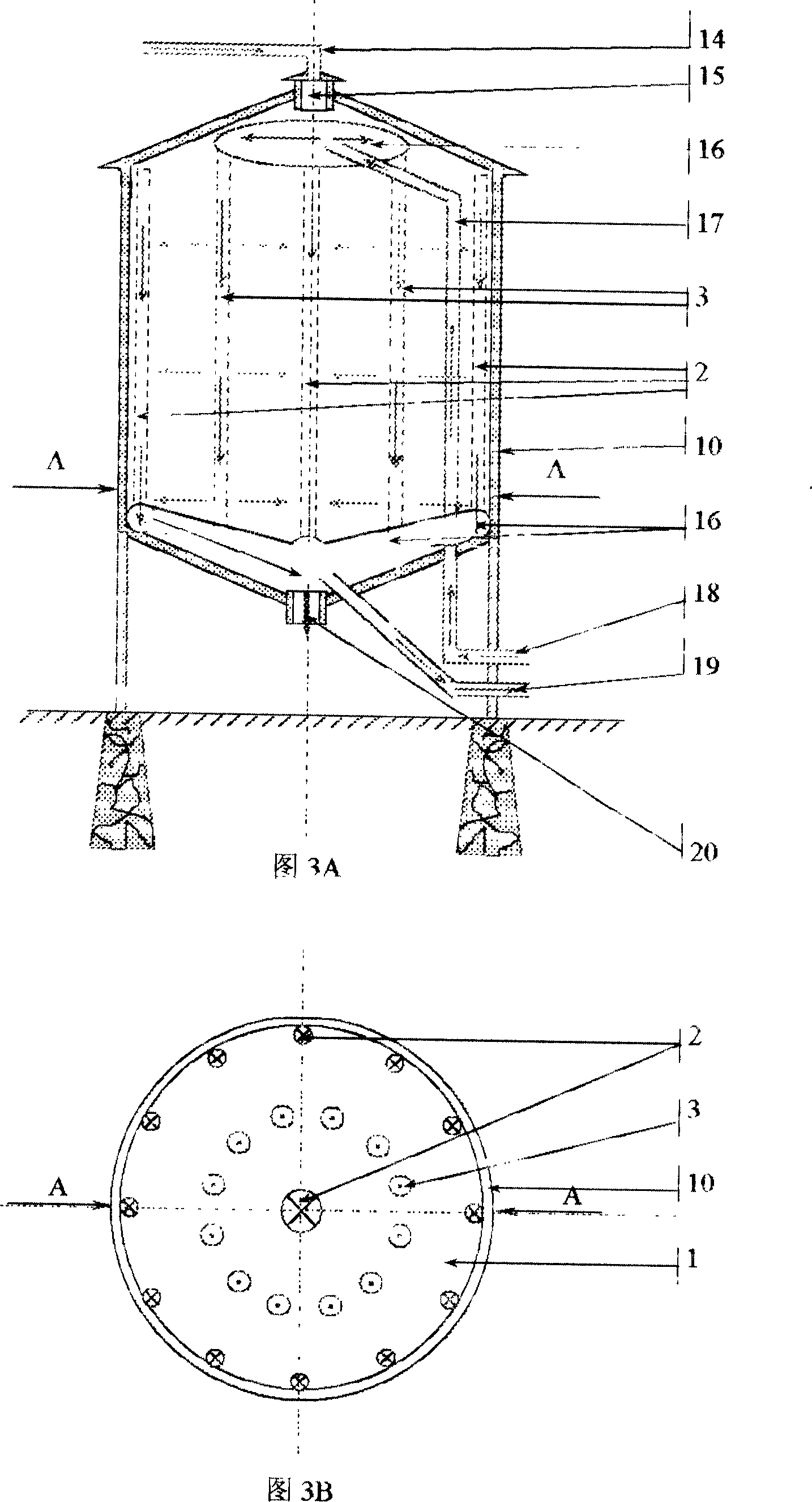

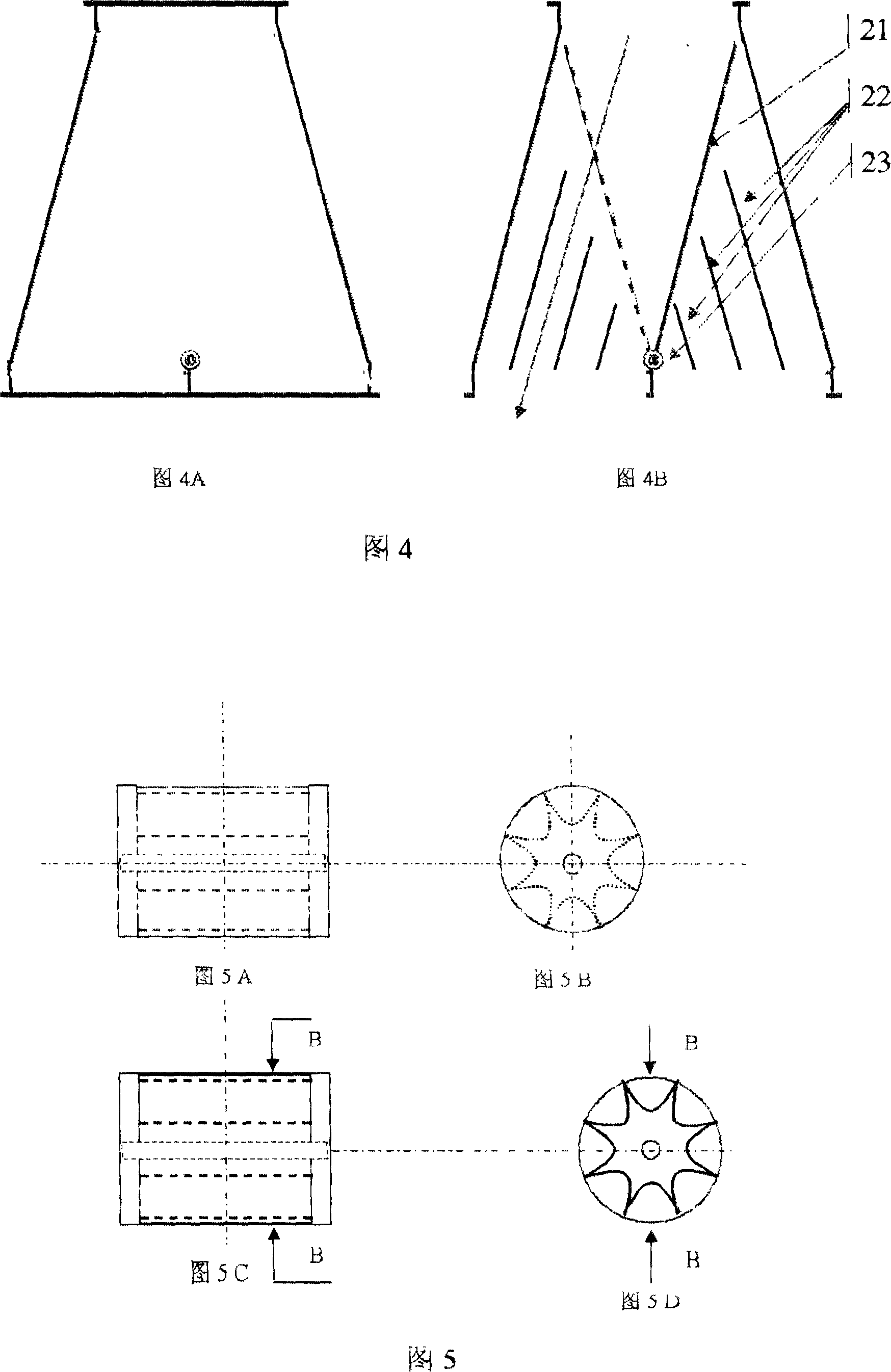

[0016] As shown in the drawings in the specification, the present invention consists of a pair of left and right cylindrical double-layer thermal insulation steel silos (1), a hot blast stove (13) that provides hot air at 50°C, a set of air ducts, and an electric fan for intake and exhaust. (7) (5) One each, and the five major components of the electric control power distribution system (9); there are air flow forward and reverse doors (11) in the air transmission pipeline, left and right warehouse conversion switches (4); cylindrical double-layer The warehouse wall (10) of the thermal insulation steel silo (1) is welded by profiles and plates, and the air diffuser (2) (3) is evenly erected in the warehouse, connected with the air diffuser (2) (3) The gas deceleration buffer chamber (16), the grain inlet (15) is installed in the middle of the top of the umbrella-shaped silo cover, the roller-shaped grain inlet switch is installed in the middle of the grain inlet (15) (Figure 7ABCD...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com