Antiforge fibre, its antiforge use and yarn with health-care function using the fibre

A technology of anti-counterfeit fiber and anti-counterfeit yarn, which is applied in fiber processing, short fiber formation, yarn and other directions, and can solve the problems that health-care functional textiles cannot be demonstrated intuitively and ordinary consumers are difficult to distinguish the authenticity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] Preparation of anti-counterfeiting fiber:

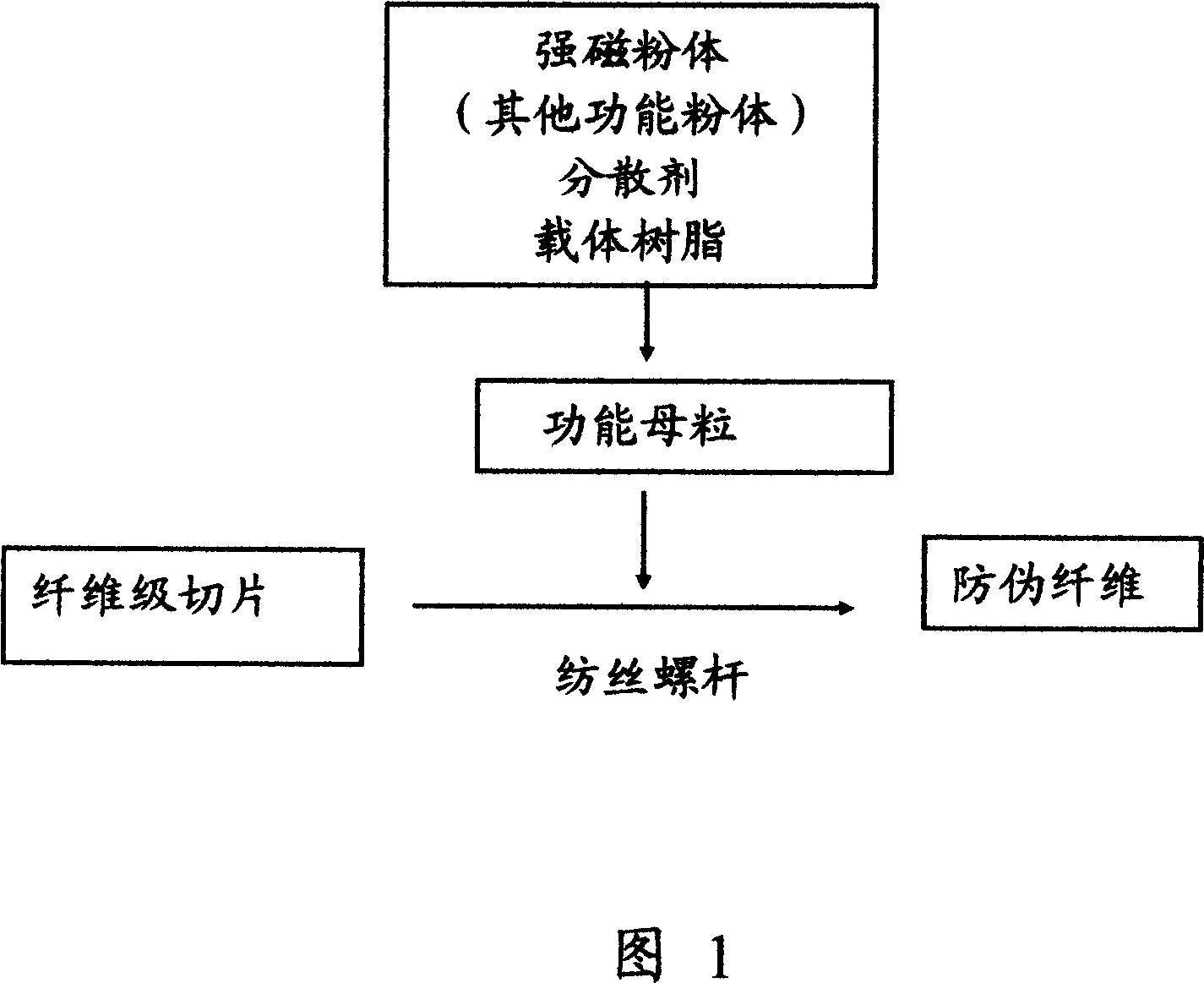

[0030] The anti-counterfeiting fiber preparation process is shown in the flow chart shown in Figure 1.

Embodiment 1

[0031] Embodiment 1, the anti-counterfeit polyester staple fiber containing 4.6% samarium cobalt permanent magnet

[0032] Preparation of functional masterbatch:

[0033] 62 parts by weight of polyester chips (Sanren brand fiber-grade polyester chips produced by Shanghai Petrochemical), 20 parts by weight of samarium cobalt permanent magnets (produced by Shanghai Yuelong Chemical Factory), 15 parts by weight of polyethylene wax, and 2 parts by weight of stearic acid Calcium and 1 part by weight of titanate are put into a high-speed mixer to fully mix the powder and polyester chips. Functional masterbatch is made by extruding with twin-screw extruder (STS-35 produced by Keya), cooling and pelletizing.

[0034] Preparation of anti-counterfeiting fiber:

[0035]Get masterbatch 23 weight parts, add in 77 weight parts polyester chips (Shanghai Petrochemical Sanren brand fiber grade polyester chips), spin after vacuum drying (spinning temperature is controlled at 280 ℃), carry out...

Embodiment 2

[0036] Embodiment 2, anti-counterfeiting polyester staple fiber containing 7.5% samarium cobalt permanent magnet and 1.125% ceramic powder

[0037] Preparation of functional masterbatch:

[0038] 60 parts by weight of polyester chips (Sanren brand fiber-grade polyester chips produced by Shanghai Petrochemical), 20 parts by weight of samarium cobalt permanent magnets (produced by Shanghai Yuelong Chemical Plant), 3 parts by weight of ceramic powder (produced by Shanghai Gaona), 15 parts by weight Put polyethylene wax in parts by weight, calcium stearate in 2 parts by weight, and titanate in 1 part by weight into a high-speed mixer to fully mix the powder and polyester chips. Functional masterbatch is made by extruding with twin-screw extruder (STS-35 produced by Keya), cooling and pelletizing.

[0039] Preparation of anti-counterfeiting fiber:

[0040] Take 37.5 parts by weight of the masterbatch, add it to 62.5 parts by weight of polyester chips, spin it after vacuum drying ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface magnetic induction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com