Permanent magnetic generator for vehicle

A permanent magnet generator and generator technology, applied to synchronous motors with stationary armatures and rotating magnets, electrical components, electromechanical devices, etc., can solve problems such as high cost and complex structure of fully-controlled rectifier bridges

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

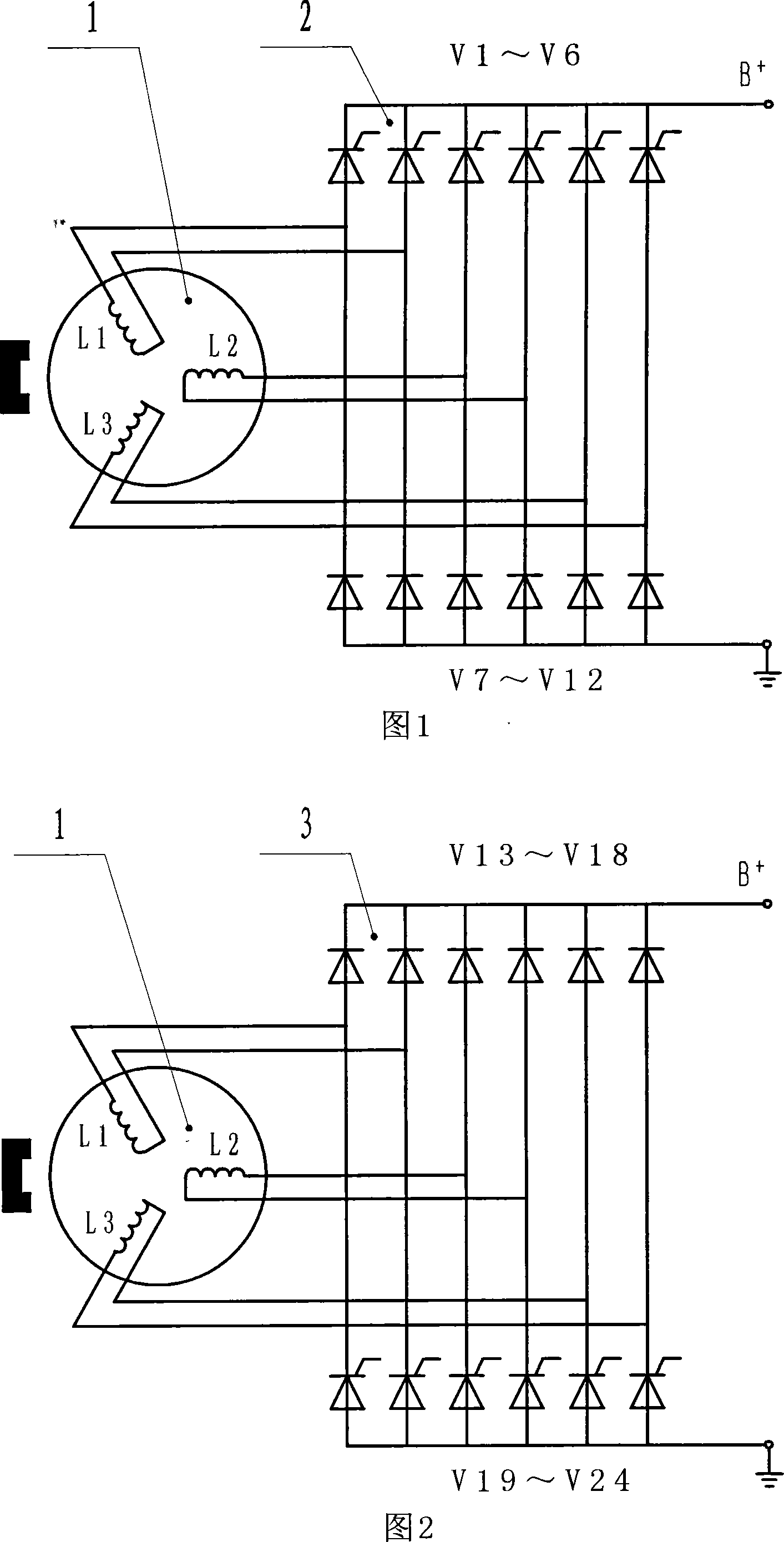

[0006] Embodiment 1: As shown in Figure 1, the rectifying voltage stabilizer (2) is a bridge-type semi-controlled rectifying and stabilizing circuit composed of 6 bridge arms, and each bridge arm is composed of 1 rectifying diode and 1 thyristor. 6 thyristors V1-V6 are connected with common cathode, and 6 rectifier diodes V7-V12 are connected with common anode. The permanent magnet generator (1) has three-phase windings L1, L2 and L3, each phase winding is independently output, and there is no connection between the windings, that is, the traditional Y-type or Δ-type connection is not used, and each phase winding has two leads There are 6 outgoing wires in total, which are respectively connected to 6 bridge arms. Although the permanent magnet generator (1) is a three-phase permanent magnet synchronous generator, since there is no connection between the windings, each phase winding works independently, which is equivalent to three independent single-phase generators. combinati...

Embodiment 2

[0007] Embodiment 2: The solution consists of two parts, a permanent magnet generator (1) and a rectifier regulator (3), as shown in Figure 2. The rectifier voltage stabilizer (3) also has a 6-arm structure, and its characteristics are: 6 thyristors V19-V24 are connected with a common anode, and 6 rectifier diodes V13-V18 are connected with a common cathode. Other structures, working principles and working processes are basically the same as in "Embodiment 1".

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com