Exhaust emission control device and internal combustion engine equipped with the exhaust emission control device and particulate filter regenerating method

一种微粒过滤器、排气气体的技术,应用在排气处理装置的电控、排气装置、化学仪器和方法等方向,能够解决PM堆积量误判断、不能充分确保可靠性、增大等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

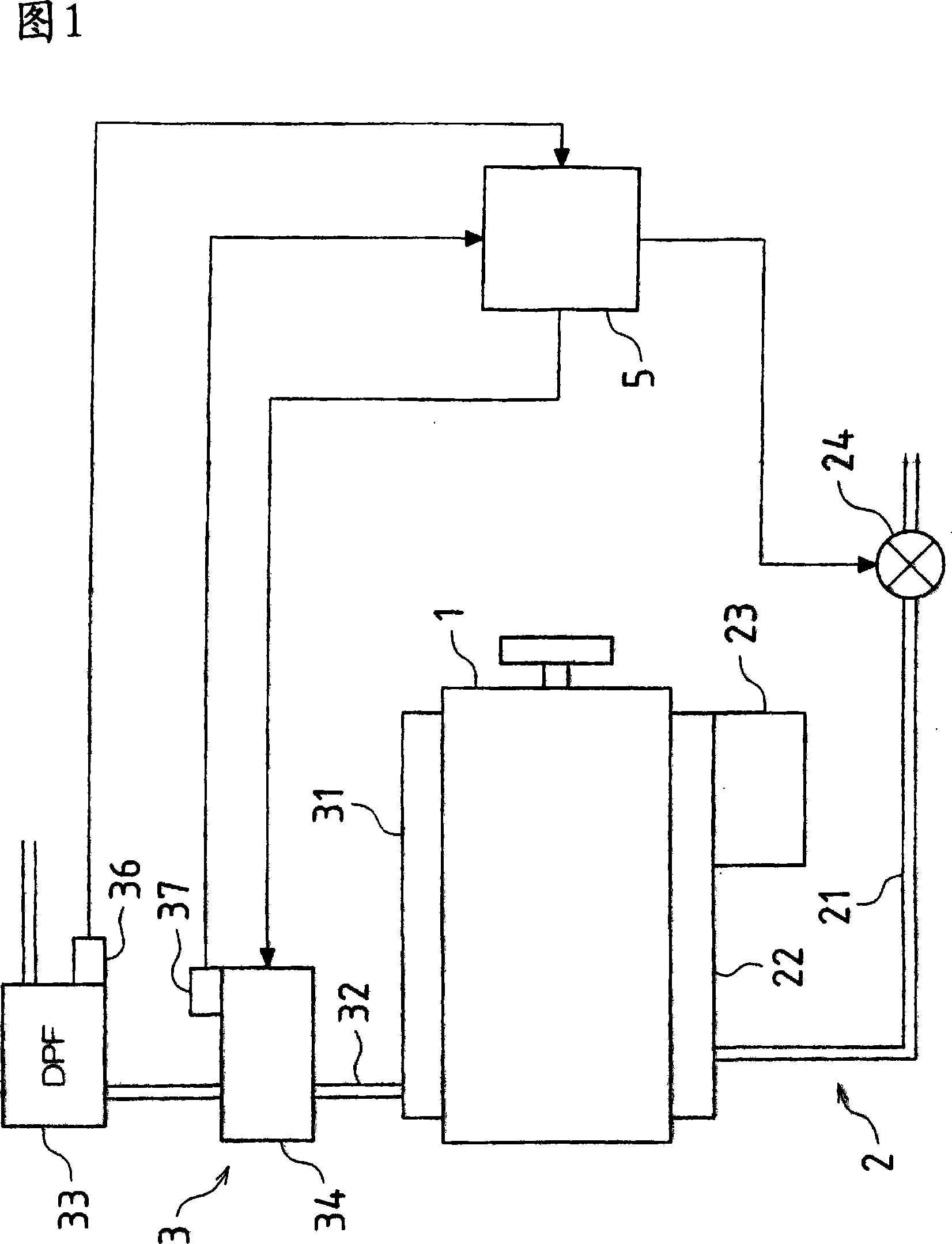

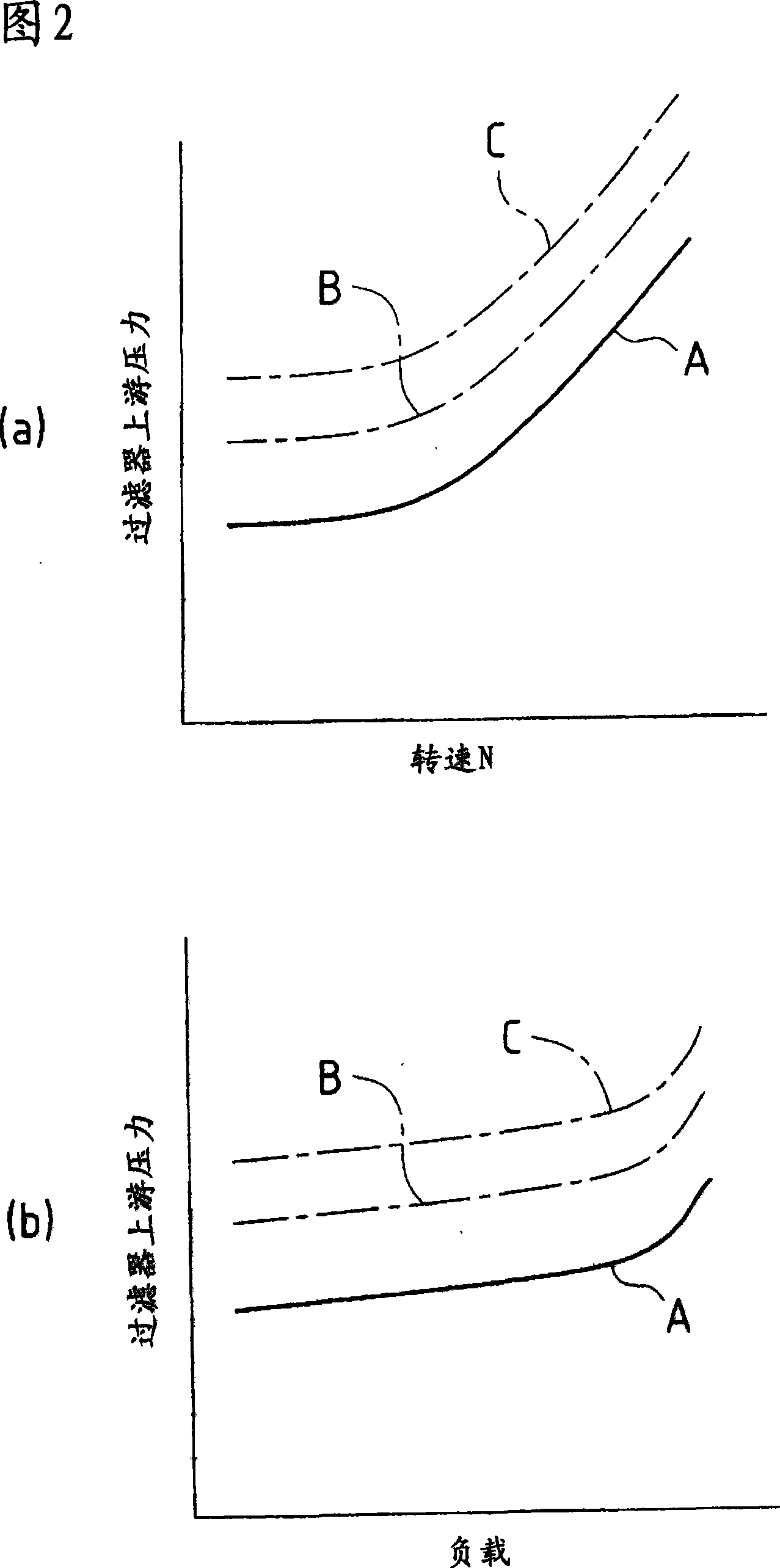

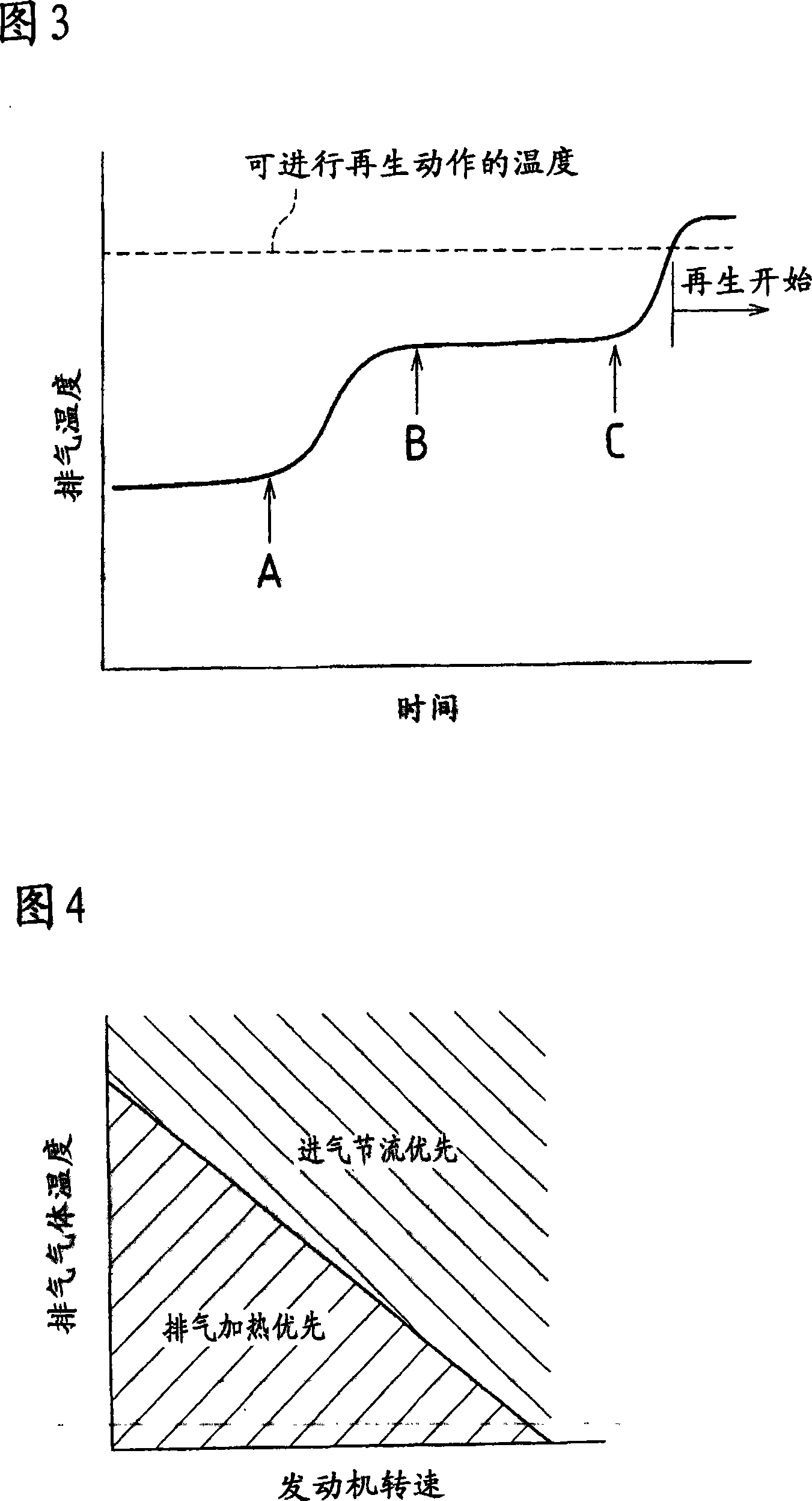

[0198] In the present embodiment, the air intake throttle device 24 and the exhaust temperature raising device 34 are controlled based on the PM accumulation amount inside the DPF 33 and the exhaust gas temperature. That is, when the controller 5 receives the PM accumulation amount detection signal from the PM accumulation amount detection sensor 36 and determines that the PM accumulation amount inside the DPF 33 exceeds a predetermined amount, and the controller 5 receives the PM accumulation amount detection signal from the exhaust gas temperature detection sensor 37 When it is determined that the exhaust gas temperature has not reached the above-mentioned temperature at which the regeneration operation can be performed (hereinafter, the case where these two conditions are satisfied is referred to as "the case where the exhaust gas temperature increase control start condition is satisfied"), By operating one or both of the air intake throttling device 24 and the exhaust tempe...

no. 2 approach

[0221] Next, a second embodiment will be described. This embodiment is a modified example related to the "limit value" which defines the limit of the air intake throttle amount in the above-mentioned first embodiment. Since other configurations and control operations are the same as those of the first embodiment, descriptions of the parts common to the first embodiment are omitted here.

[0222] As described above, when the amount of intake air is reduced by the air intake throttling operation of the air intake throttle device 24, the ignition timing of the air-fuel mixture is delayed. As a result, incomplete combustion occurs, and the amounts of CO and THC in the exhaust gas gradually increase. FIG. 6 shows the relationship between the meter-in amount and the concentrations of CO and THC in the exhaust gas. In this way, although in the region where the meter-in flow is relatively small, the increase ratio of the concentration of CO and THC relative to the increase in the me...

no. 3 approach

[0234] Next, a third embodiment will be described. In the present embodiment, an electric heater is used as the exhaust temperature raising device 34, and power supply to the electric heater 34 is directly performed by an alternator. Since other configurations and control operations are the same as those of the above-mentioned first embodiment and second embodiment, descriptions of parts common to the first embodiment and second embodiment are omitted here.

[0235] As shown in FIG. 10 , the engine according to this embodiment is provided with an alternator 61 that generates electricity by receiving the rotational driving force of the crankshaft on the side surface of the engine main body 1, and part of the electric power generated by the alternator 61 is supplied to the electric heater. (Exhaust heating device) 34. The ON / OFF switching of the power supply to the electric heater 34 is performed by the exhaust gas temperature increase control signal from the controller 5 as in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com