Rotary actuator

A technology of rotary actuators and rotary valves, applied to engine components, fluid pressure actuators, mechanical equipment, etc., to achieve the effect of number of parts, smooth action, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

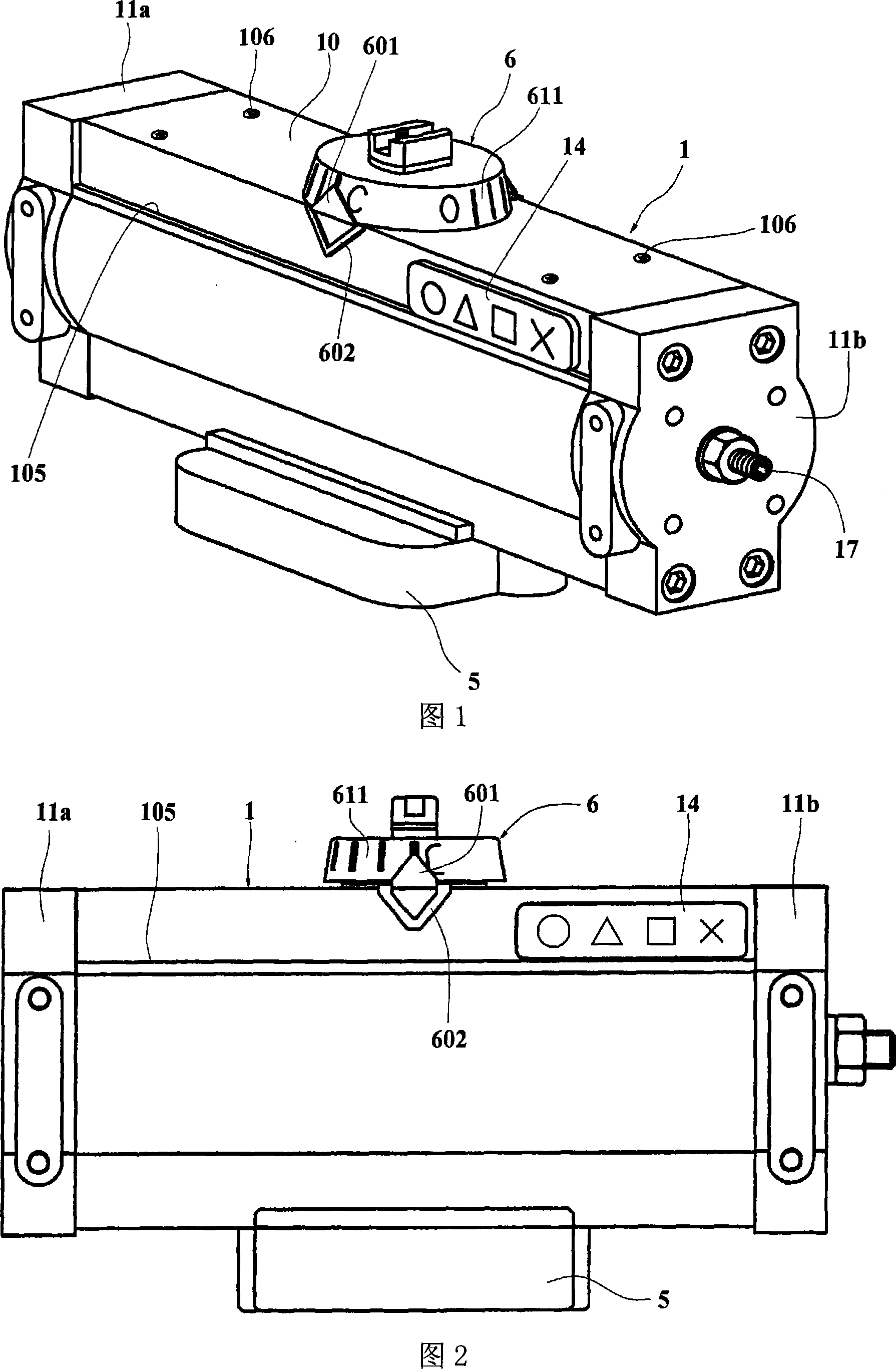

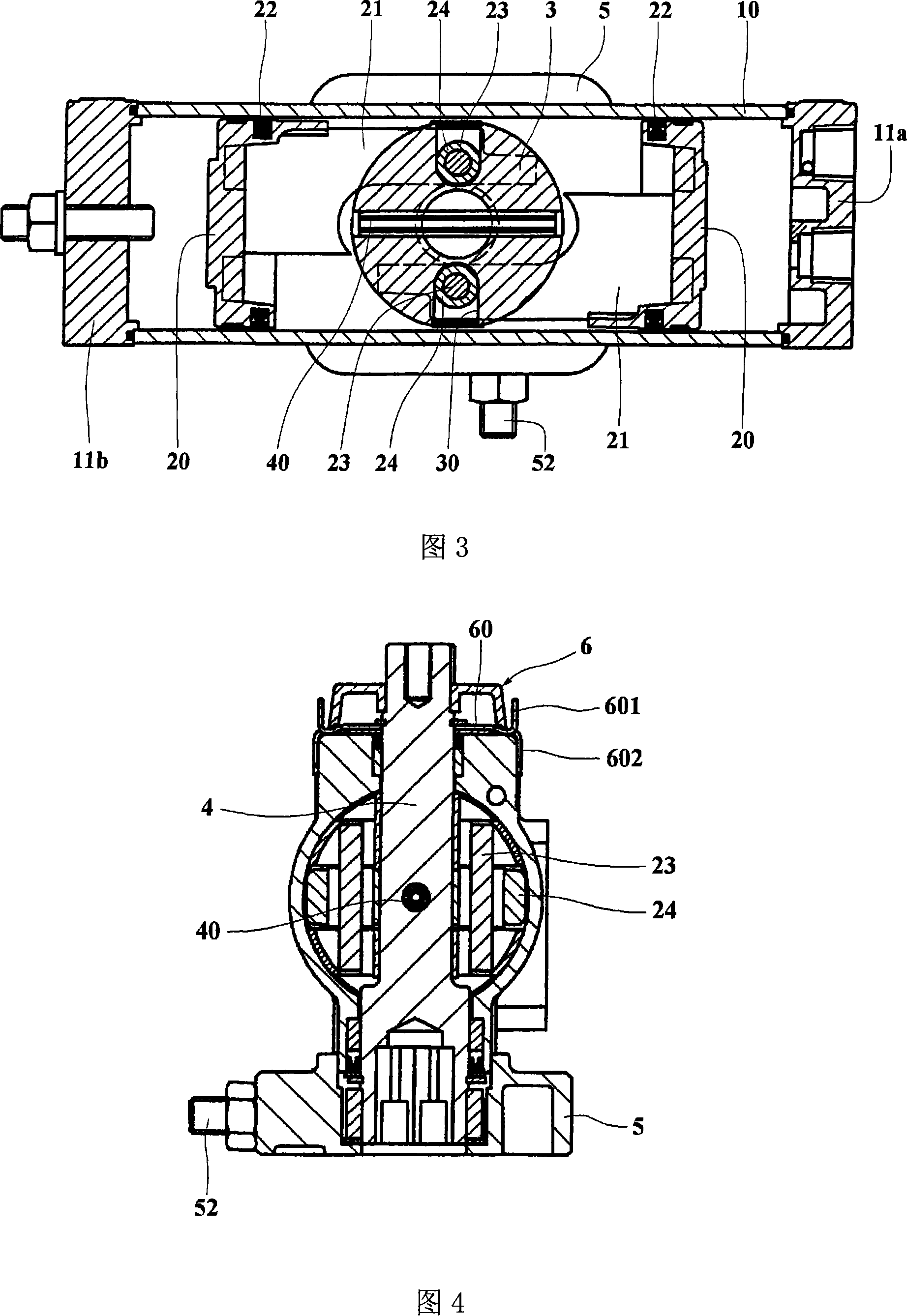

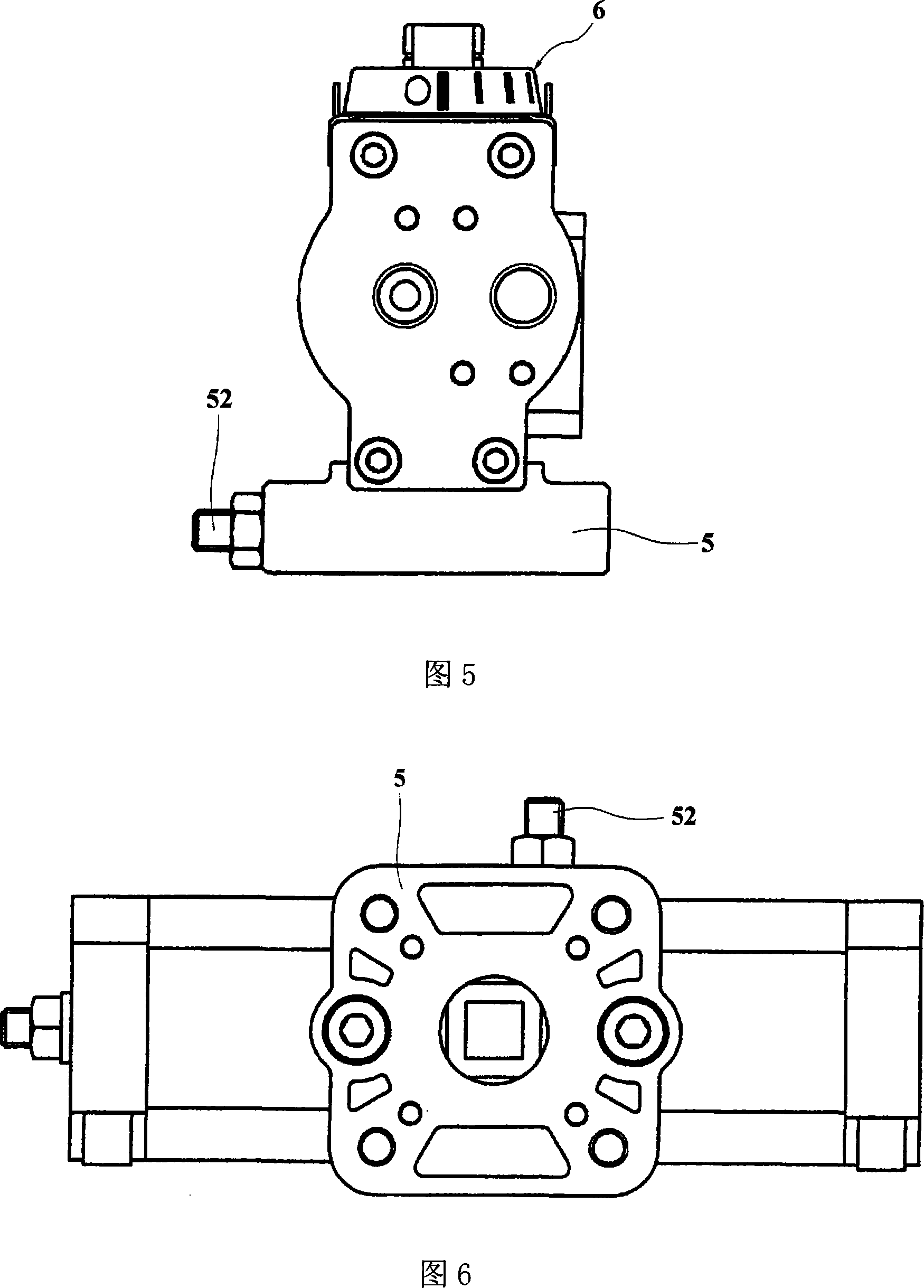

[0130]The best mode for carrying out the present invention will be described in detail below. The present invention relates to a valve stem driving device of a rotary valve having a rotating valve body such as a butterfly valve, that is, a rotary actuator, which has a structure in which an output shaft is connected to a piston reciprocating in a cylinder under the pressure of a pressurized fluid through a yoke. Above, the reciprocating motion of the piston is converted into a rotary motion to drive the rotary output shaft, thereby driving the valve stem of the rotary valve connected with the output shaft. A piston that moves in the cylinder body under fluid pressure such as air pressure, a disc-shaped piston portion that is in sliding contact with the inner surface of the cylinder body and a front end portion of the piston rod that extends axially from the piston are equipped with a slide that is in sliding contact with the inner surface of the cylinder. The two sliders are ar...

Embodiment

[0148] The present invention relates to a rotary actuator. According to the embodiments described in the drawings, the object is butterfly valves, but it is not limited to driving butterfly valves. As an actuator with a rotating valve stem, the valve can be opened and closed by driving and rotating the valve stem from the outside. Rotary actuators for so-called rotary valves can be used for a wide variety of valves. Referring to Figures 1 to 6, the rotary actuator has a cylinder (1); a piston (2) that reciprocates in the cylinder (1) under the pressure of the pressurized fluid; and a piston (2) that converts the reciprocating motion of the piston (2) into rotational motion The stop yoke (3), which transmits the rotational movement of the stop yoke (3) to the output shaft (4) of the valve stem, reciprocates the piston (2) by controlling the direction of the pressure fluid applied to the piston with the required control device Movement, the output shaft (4) is rotated by the rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com