Production method and control device for developing single crystal bar in square column body

A production method and technology for single crystal rods are applied in the field of production and control devices for growing square columnar single crystal rods, and can solve problems such as uncontrollable direct growth into square columnar single crystal rods and the like.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

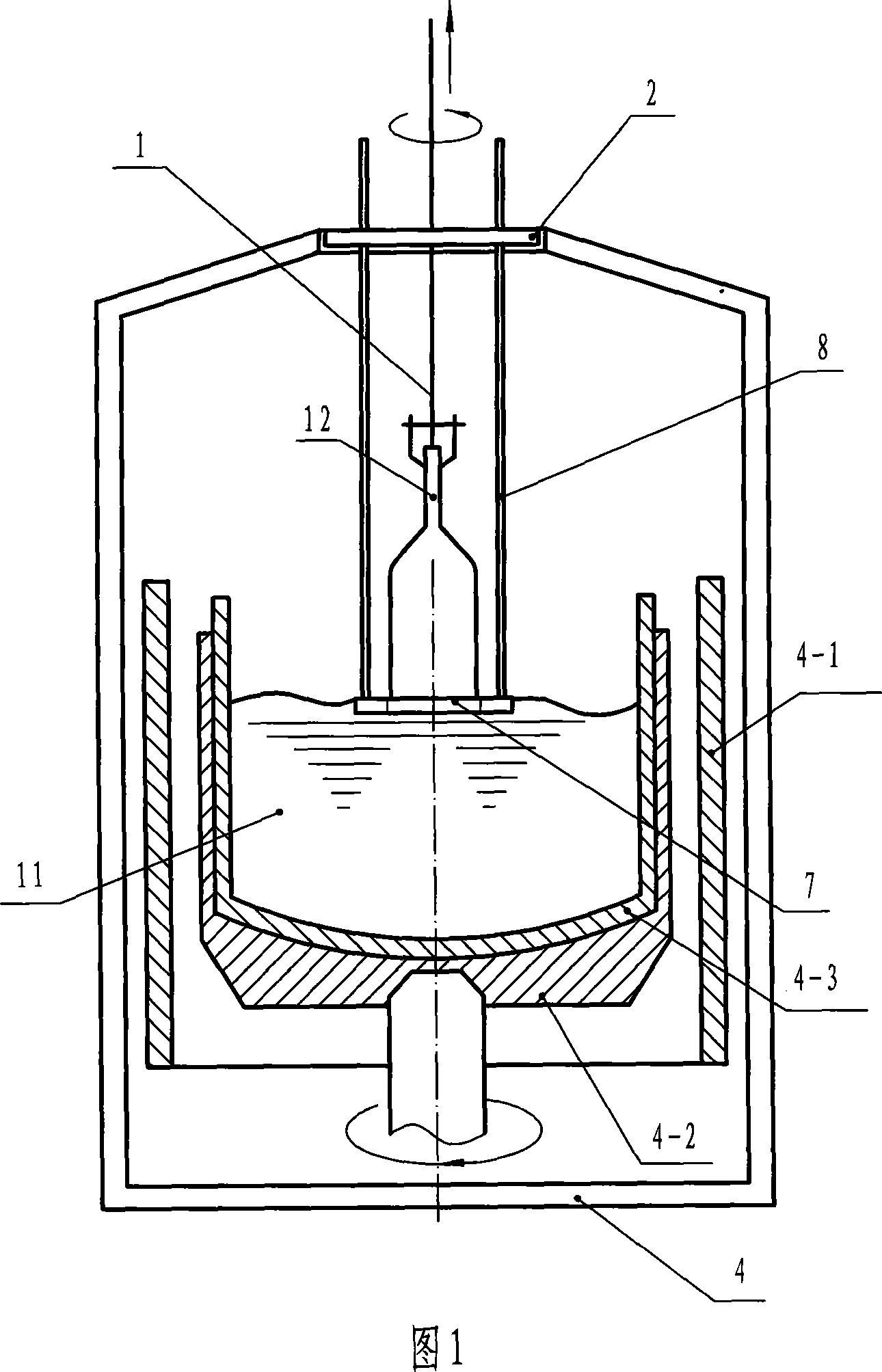

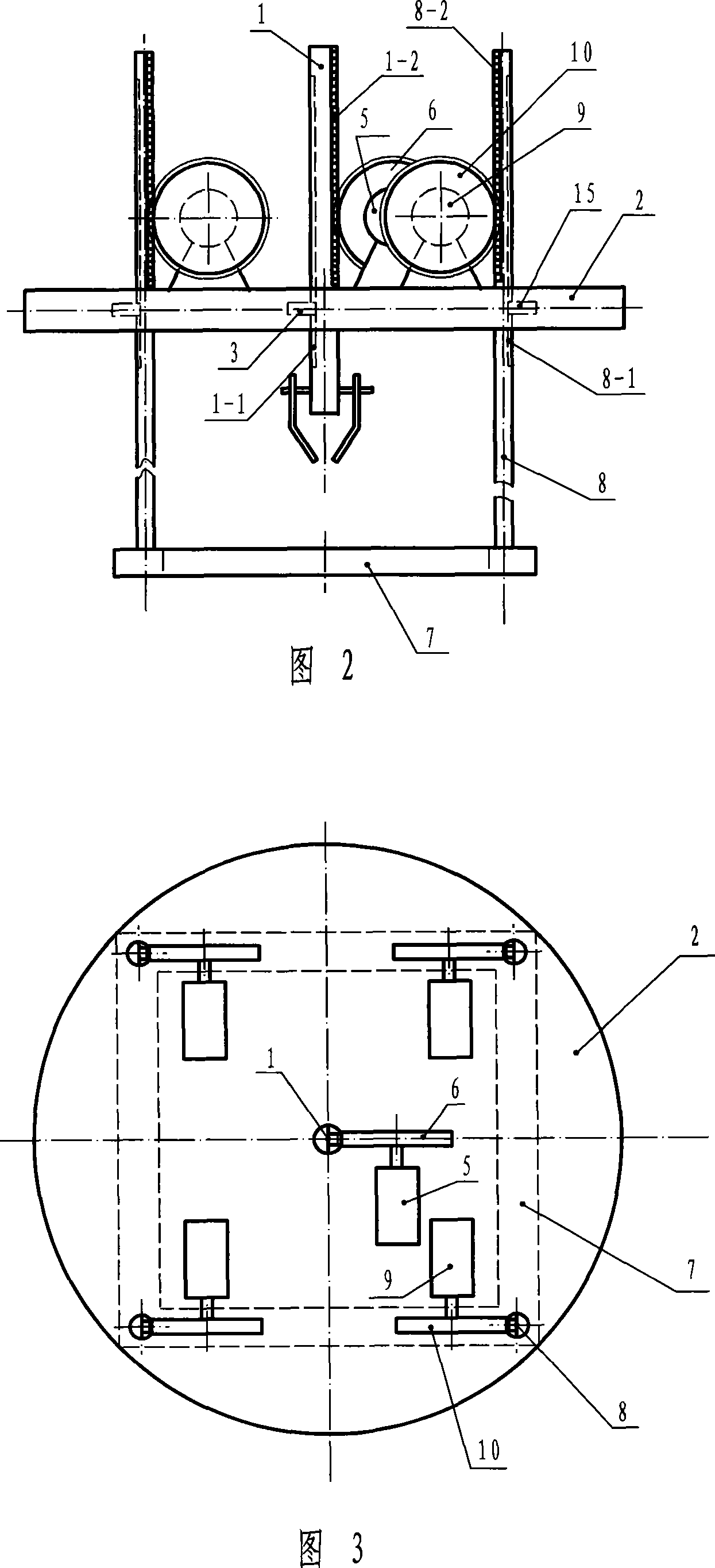

[0023] Referring to Fig. 1, 2, 3, the control device of the present invention includes a seed crystal holder 1 and a rotary disk 2 that drives the seed crystal holder 1 to rotate, and a top half of the seed crystal holder 1 is provided with Axial keyway 1-1, a pin key 3 is provided on the holder hole in the center of the rotating disk 2, the seed crystal holder 1 and the rotating disk 2 are connected together through the keyway 1-1 and the pin key 3 , the use of this connection structure can not affect the axial up and down movement of the clamper 1 while rotating. In order to drive the seed crystal holder to move up and down, the upper end of the seed crystal holder 1 has a flat tooth structure 1-2, and a rotating disk 2 is provided to drive the seed crystal holder to move up and down. Servo drive motor 5, the torque output shaft of the servo drive motor 5 is connected with a gear 6, which meshes with the flat tooth structure 1-2 on the upper end of the seed crystal holder. ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap