Compression joint type elements and parts board, and method for connecting the board to experimental board

A component and crimping technology, which is applied in the field of crimping component boards and their access test boards, can solve the problems of reduced experimental efficiency and success rate, virtual welding and short-circuit faults, and large numbers, and saves experiments. Cost, reduced contact resistance, good shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

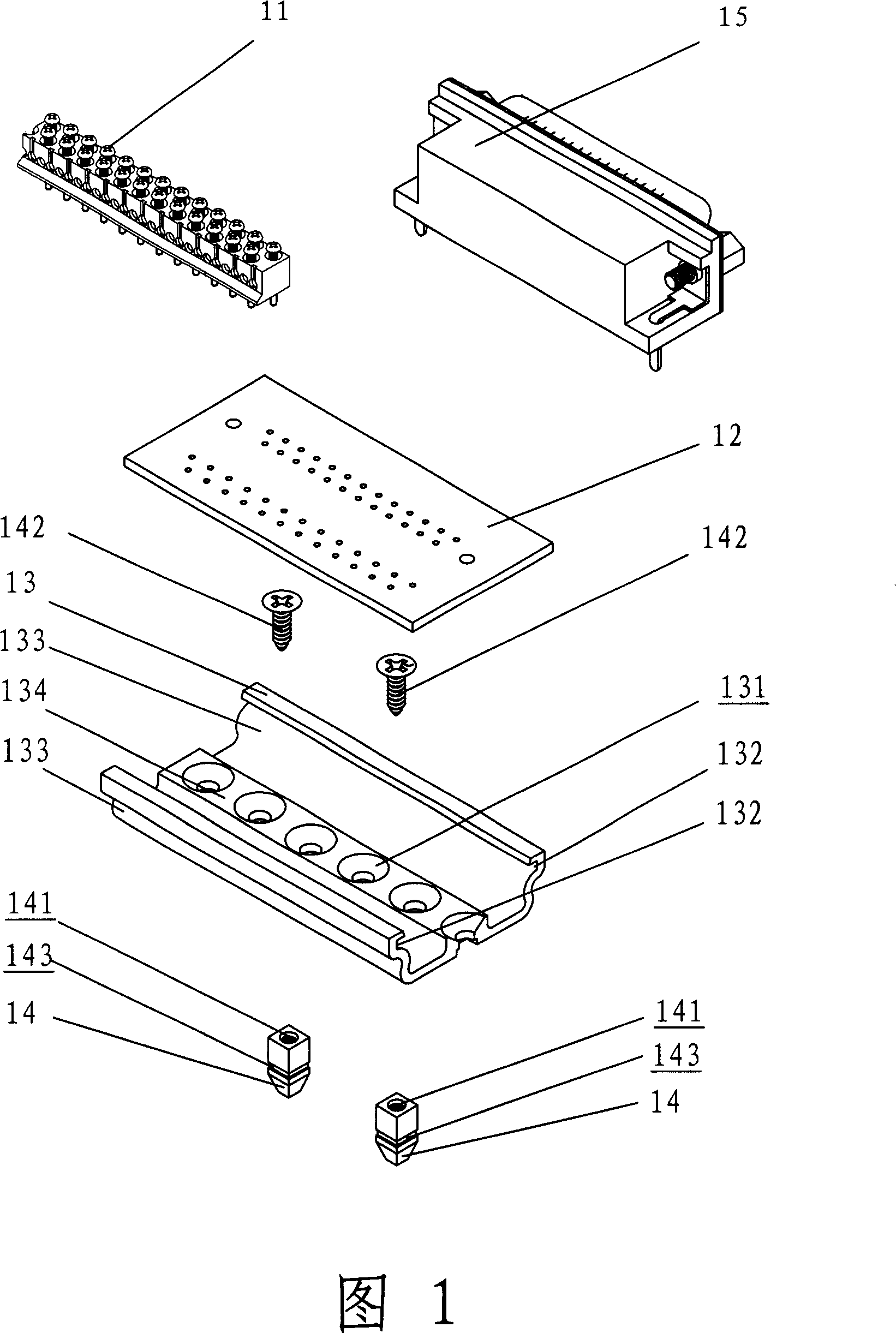

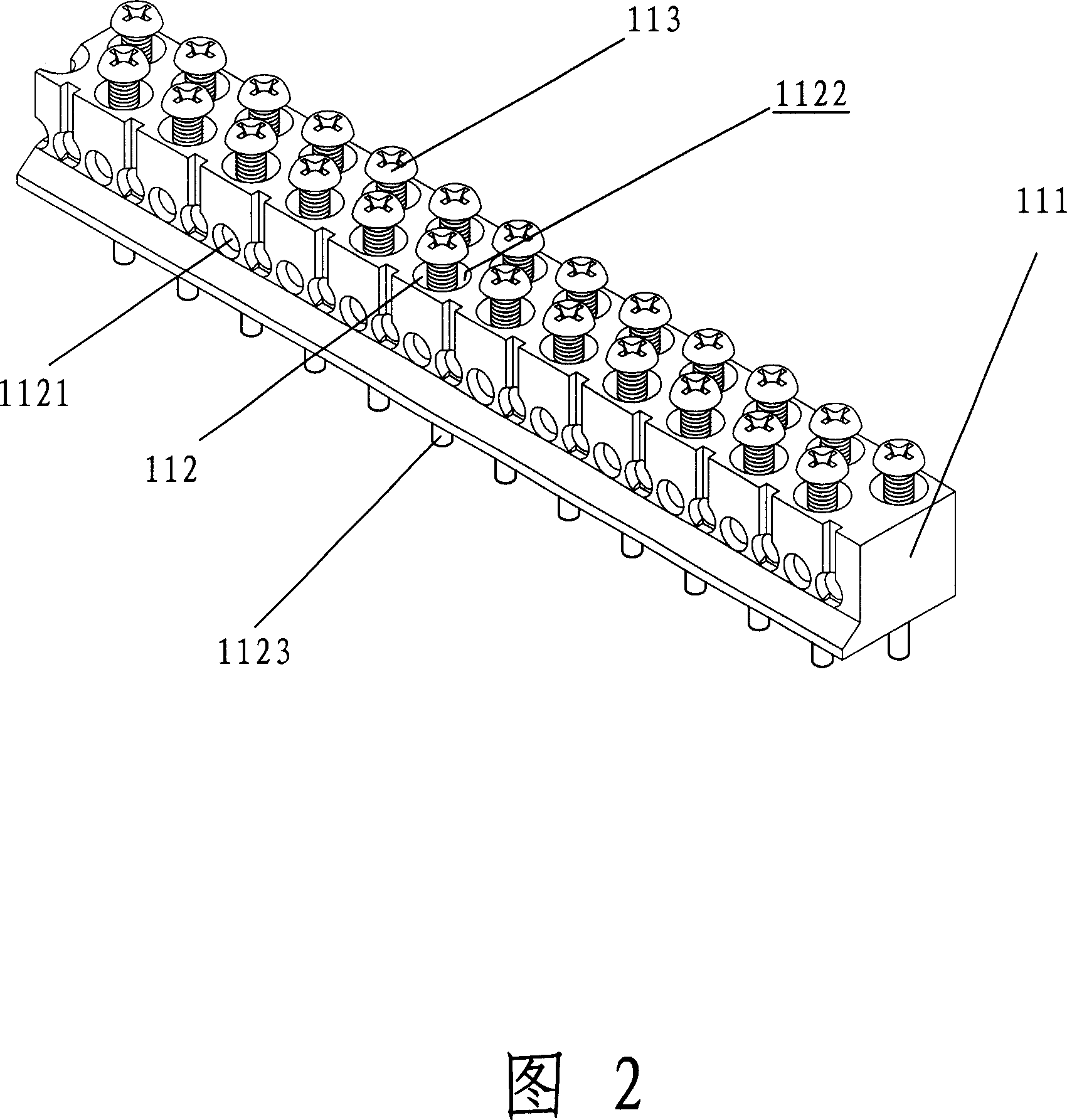

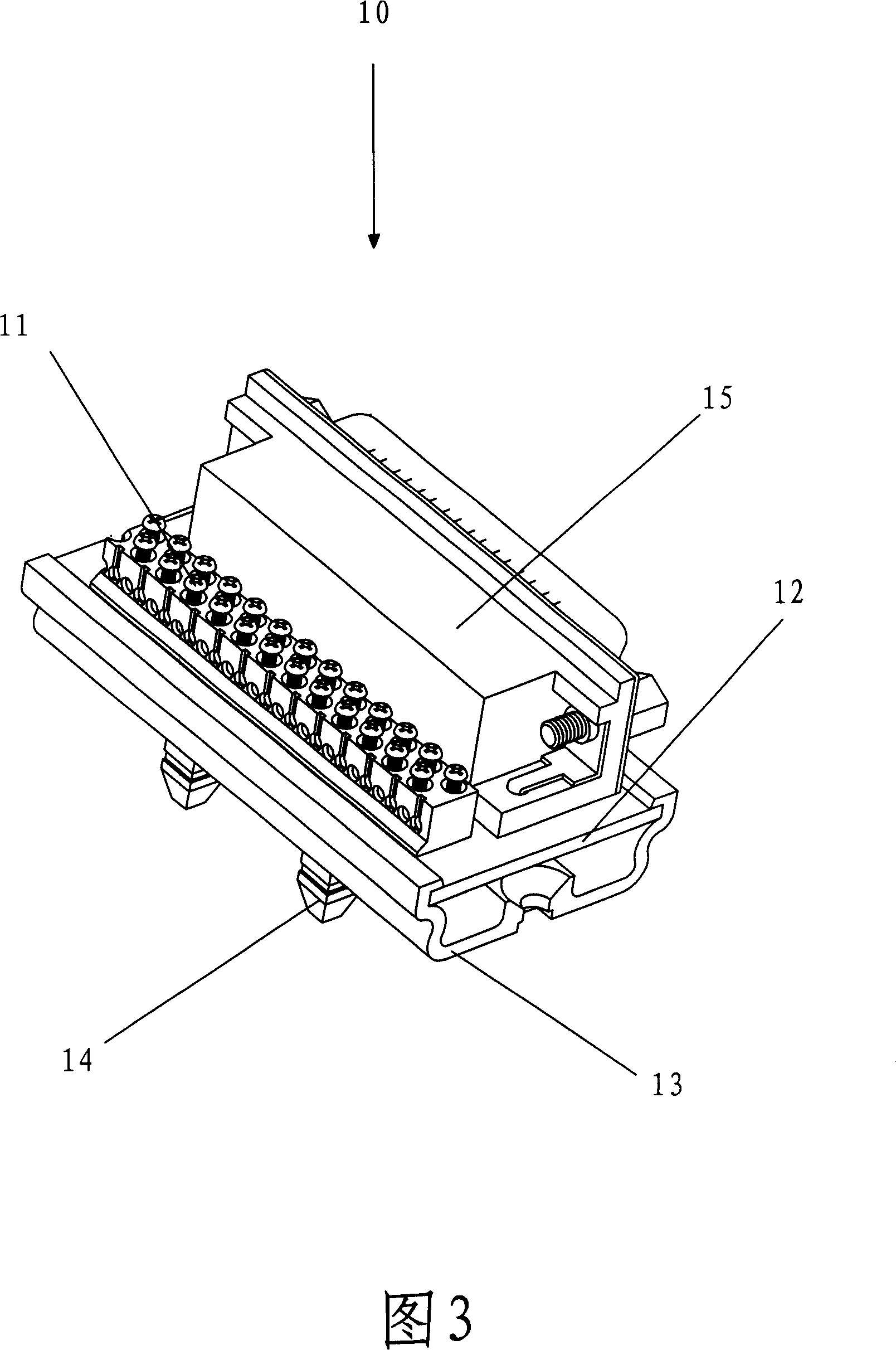

[0034] Specific embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements. First please refer to FIG. 1 and FIG. 3 , the crimping type component board 10 of the present invention includes components 15 , wiring bars 11 , printed circuit board 12 , board base 13 and mounting feet 14 .

[0035] The components 15 are generally weak current components and embedded unit circuits that can be directly installed on the circuit board, such as triodes, thyristors, integrated circuits, variable resistors, variable capacitors, input and output interfaces and various system cards The components 15 are generally soldered on the predetermined printed circuit board 12 and electrically connected to the circuit on the printed circuit board 12 .

[0036] The printed circuit board 12 is generally an epoxy resin printed circuit board. The circuit design and specification design are carried out according to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com