Composition, compound body, and method for raising utilization ratio of catalyst

A utilization rate and composite technology, applied in chemical instruments and methods, catalyst carriers, chemical/physical processes, etc., can solve problems such as phase separation, catalyst particles evacuating polymers, cracks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1, prepare electrode with the method of the present invention

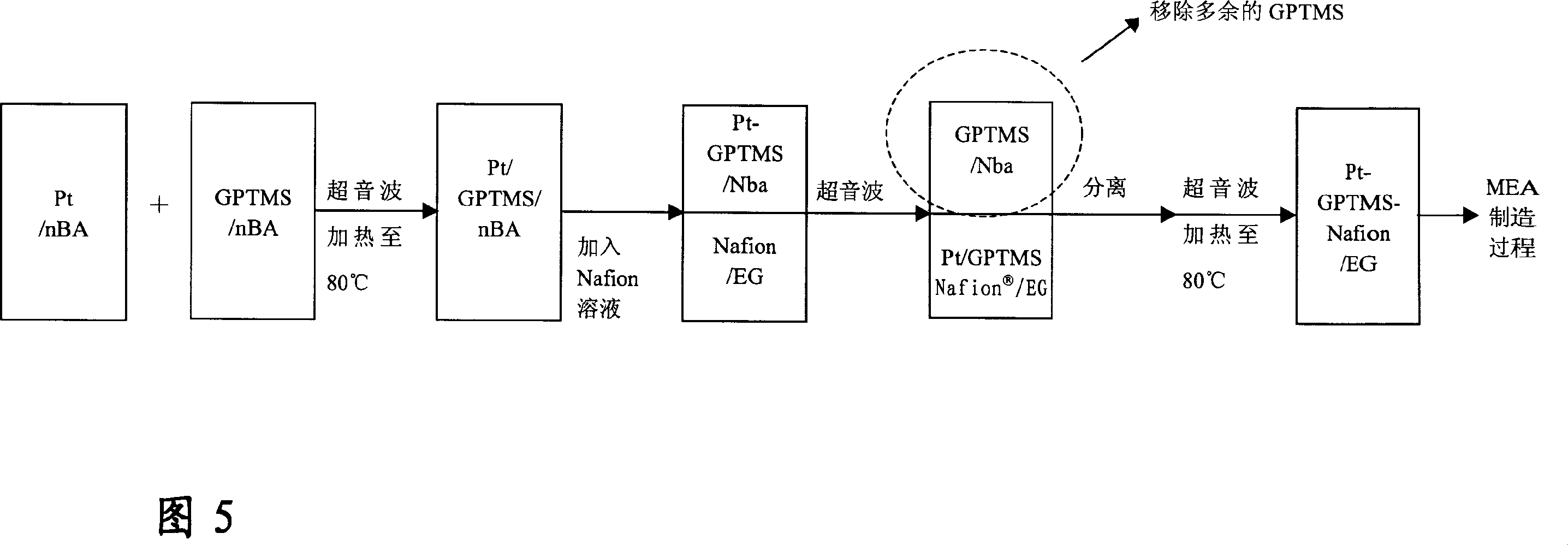

[0038] The process of preparing an electrode by using the method for improving the utilization rate of fuel cell catalyst of the present invention is shown in FIG. 5 . First, disperse Pt and coupling agent GPTMS in nBA with ultrasonic waves to form Pt / nBA and GPTMS / nBA, and mix Pt / nBA and GPTMS / nBA according to the ratio of Pt:GPTMS=100:2, and heat to 80°C Disperse with ultrasound. Next, according to Pt: Nafion = Add Nafion at a ratio of 4:1 / EG, using ultrasonic waves to precipitate the reacted Pt-GPTMS / EG in the lower EG, and the supernatant liquid is excess GPTMS. After separating and removing the excess GPTMS, heat it to 80°C and disperse it with ultrasonic waves to obtain ProductPt-GPTMS-Nafion / EG. Finally, the product is subjected to an electrode manufacturing process, and the prepared electrode is further prepared into a thin film electrode module (MEA).

Embodiment 2

[0039] Embodiment two, catalyst slurry DLS test

[0040] The composition prepared in Example 1 was used to measure the particle size of the slurry using a dynamic light scattering instrument (Dynamic Light Scattering, DLS).

[0041] According to Figure 6, when the solvent is water, it can be found that the slurry with coupling agent (Coupling Agent) is more than the slurry without coupling agent (Previous Method), and its analysis value is from a larger particle size to a smaller particle size offset. This is because the coupling agent is bonded to the catalyst to disperse the catalyst evenly, making the particle size of the distribution smaller than that of the catalyst without the coupling agent, and the catalyst without the coupling agent will aggregate to cause the particles to become larger. It can be seen that, by adding coupling agent in the present invention, the catalyst can be evenly dispersed, so that the exposed active surface area of the catalyst is increased t...

Embodiment 3

[0042] Embodiment 3, half-cell test

[0043] The PtRu / black anode slurry processed according to the method of Example 1 was made into an anode electrode, and then 10% MeOH and 0.5M H at 40°C 2 SO 4 , a half-cell oxidation reaction test was performed.

[0044] The experimental results are shown in Figure 7. It can be found that when the voltage is 0.6V, the current density of the anode slurry with GPTMS added is about 60% higher than that of the anode slurry without GPTMS, and the GPTMS-K form electrode Electrodes are improved by about 50%. The experimental results show that the catalyst slurry added with coupling agent can indeed promote the utilization rate of the catalyst, so as to improve the performance of the fuel cell.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com