New type direct methanol fuel cell

A methanol fuel cell, direct technology, applied to fuel cells, fuel cell components, circuits, etc., can solve the problems of methanol leakage, electrode activity reduction, methanol fuel loss, etc. The effect of simplifying battery structure and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

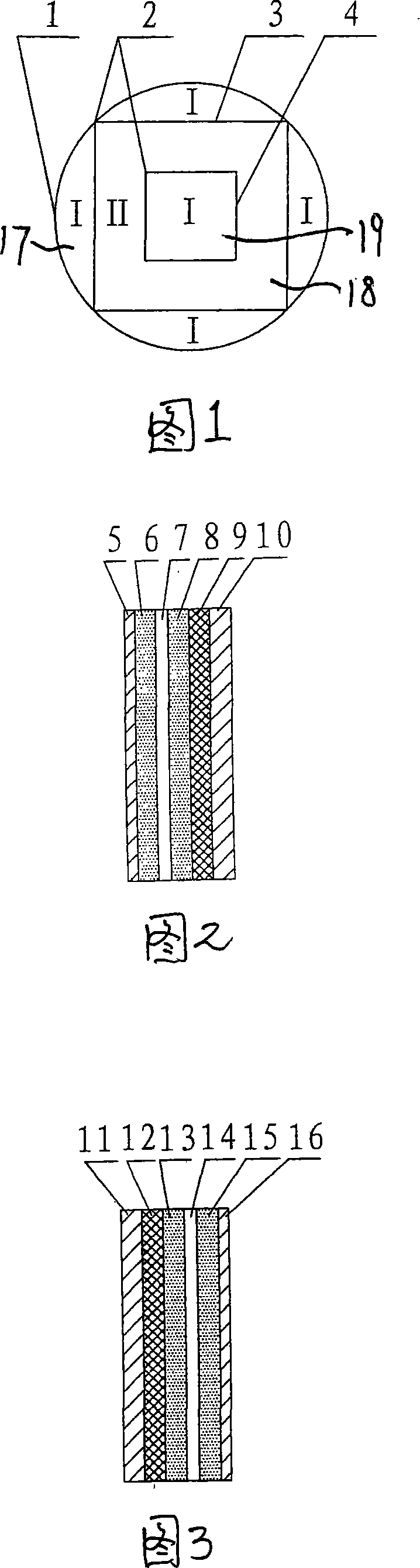

[0023] A new type of direct methanol fuel cell, comprising a battery casing 1, an external electrode 3 is arranged in the battery casing, the external electrode 3 is connected to the battery casing 1 through a welding point 2, and an air chamber 17 is arranged between the external electrode 3 and the battery casing 1, and The inner electrode 4 is arranged inside the electrode, the gel mobile phase chamber 18 is arranged between the inner electrode 4 and the outer electrode 3, and the air chamber 19 is arranged inside the inner electrode, wherein the gel mobile phase is made of the raw materials of the following weight components:

[0024] CH 3 OH 20%

[0025] h 2 SO 4 30%

[0026] h 2 O 20%

[0027] Heteroacids 3%

[0028] Conductive polymer and / or metal powder 5%

[0029] Metal organic compounds or metal salts 22%.

[0030] Metal-organic compounds are titanates (or silicates), and metal salts are sodium silicates. The heteroacid is perfluorosulf...

Embodiment 2

[0034] The weight ratio of each raw material in the gel mobile phase preparation is:

[0035] CH 3 OH 40%

[0036] h 2 SO 4 20%

[0037] h 2 O 20%

[0038] Heteroacids 5%

[0039] Conductive polymer 3%

[0040] Metal organic compounds or metal salts 12%. The conductive polymer is polyaniline (or polypyrrole).

[0041] All the other are with embodiment 1.

Embodiment 3

[0043] The weight ratio of each raw material in the gel mobile phase preparation is:

[0044] CH 3 OH 50%

[0045] h 2 SO 4 10%

[0046] h 2 O 10%

[0047] Heteroacids 10%

[0048] Conductive polymer 5%

[0049] Metal organic compound or metal salt 15%.

[0050] All the other are with embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com