Supported denitration catalyst based on pillared clay and preparation method thereof

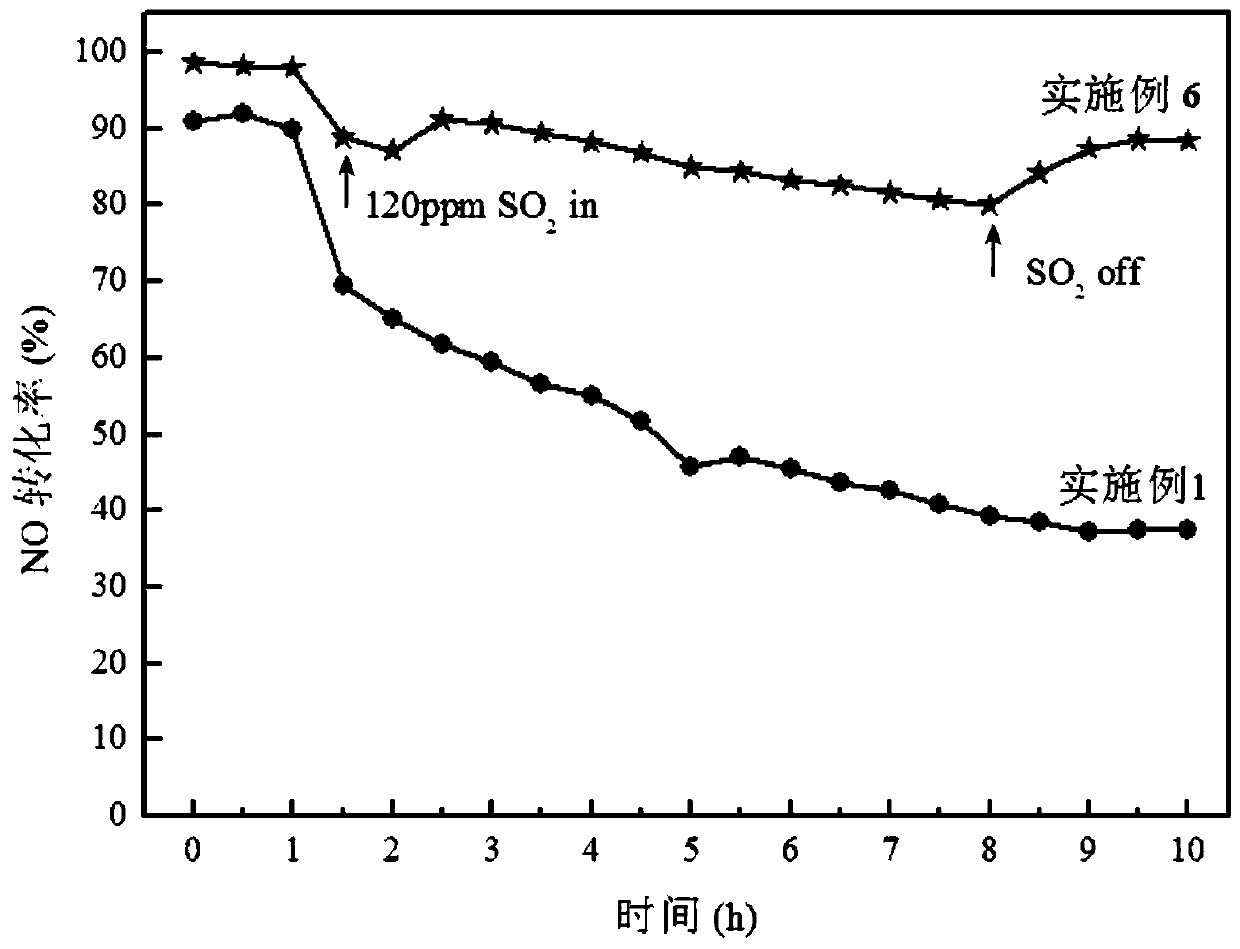

A technology of denitrification catalyst and pillared clay, which is applied in the field of denitrification catalyst, can solve the problems of unsatisfactory sulfur resistance performance, decreased denitrification efficiency, and poor effect, and achieves strong resistance to SO2 poisoning, improved sulfur resistance performance, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

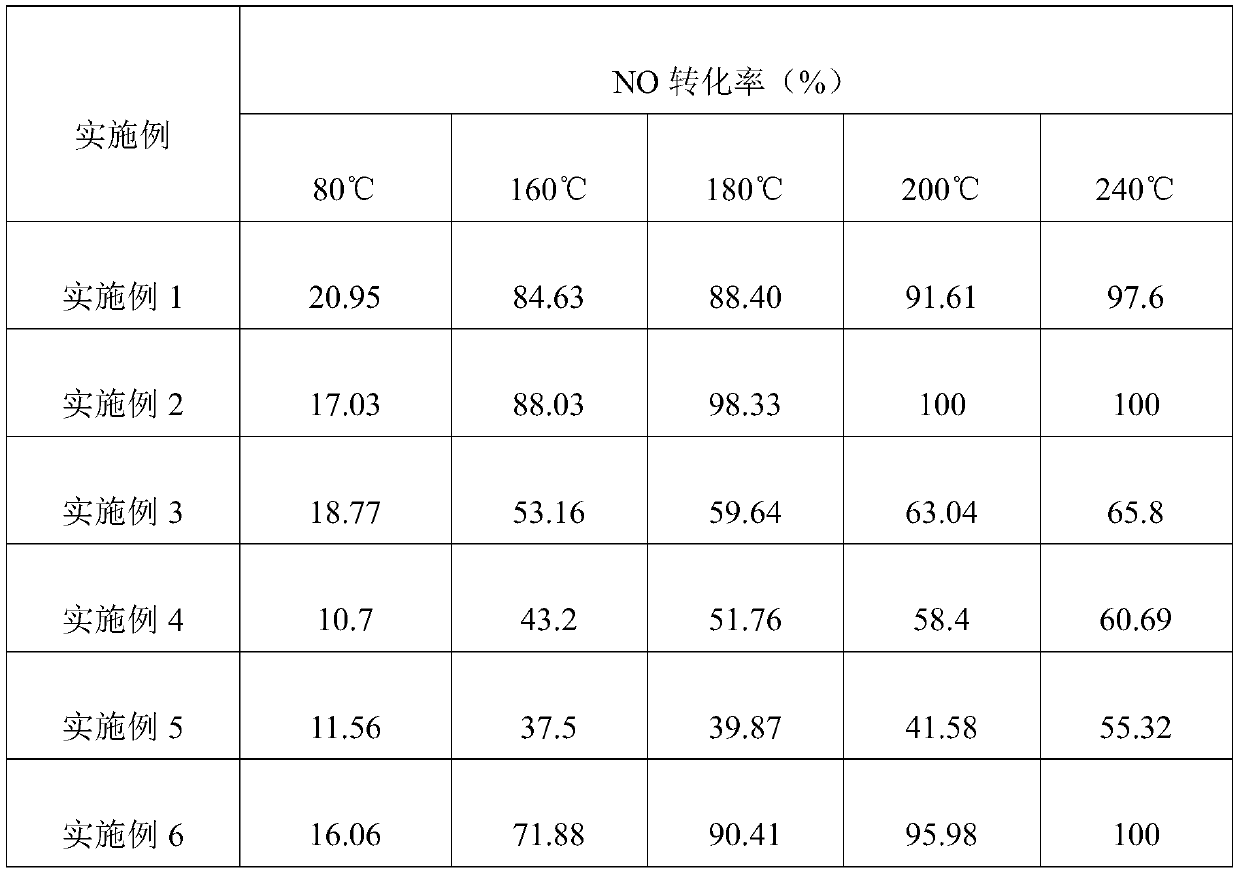

Embodiment 1

[0029] (1) Preparation of pillared clay

[0030] Take 19mL tetraethyl orthosilicate (TEOS), 5mL 2mol / L hydrochloric acid, and 5.5mL absolute ethanol, and mix them uniformly to obtain a silica sol. 2g of bentonite and water were mixed into a bentonite suspension with a mass concentration of 1%; 34mL of butyl titanate [CH 3 (CH 2 ) 30 ] 4 Ti was mixed with 1 mol / L HCL solution, and the stirring was continued for 3 hours to obtain a titanic acid mixed solution, wherein the molar ratio of H / Ti was 4. Mix the titanic acid mixed solution prepared above with the silica sol evenly, and age for 5 hours to obtain the columnizing agent; slowly drop the obtained columnizing agent into the bentonite suspension under the condition of 60°C water bath and stirring, and finish the aging for 12 hours. Then carry out centrifugation, wash and filter the separated solid product with ethanol water solution with a volume ratio of 1:1, repeat several times, place the washed solid product in an ov...

Embodiment 2

[0034] (1) Preparation of silicon-based pillared clay

[0035] Take 19mL tetraethyl orthosilicate (TEOS), 5mL 2mol / L hydrochloric acid, and 5.5mL absolute ethanol, and mix them to obtain a silica sol. 2g of bentonite and water were mixed into a bentonite suspension with a mass concentration of 1%; 34mL of butyl titanate [CH 3 (CH 2 ) 30 ] 4 Ti was mixed with 1 mol / L HCL solution, and the stirring was continued for 3 hours to obtain a titanic acid mixed solution, wherein the molar ratio of H / Ti was 4. Mix and age the prepared titanic acid mixed solution with silica sol for 3 hours to obtain a columnar agent; slowly drop the obtained columnar agent into the bentonite suspension under the condition of stirring in a water bath at 60°C, age for 12 hours after the addition, and then carry out Centrifuge, wash and filter the separated solid product with an ethanol aqueous solution with a volume ratio of 1:1, repeat several times, dry the washed solid product in a 60°C oven for 12...

Embodiment 3

[0039] (1) Preparation of silicon-based pillared clay

[0040] Take 2.43mL tetraethyl orthosilicate (TEOS), 0.5mL 2mol / L hydrochloric acid, and 0.7mL absolute ethanol, and mix them to obtain a silica sol. 2g of bentonite and water were mixed into a bentonite suspension with a mass concentration of 1%; 37.3mL of butyl titanate [CH 3 (CH 2 ) 30 ] 4 Ti was mixed with 1 mol / L HCL solution, and the stirring was continued for 3 hours to obtain a titanic acid mixed solution, wherein the molar ratio of H / Ti was 4. Mix and age the prepared titanic acid mixed solution with silica sol for 3 hours to obtain a columnar agent; slowly drop the obtained columnar agent into the bentonite suspension in a water bath at 60°C with stirring, and finish the aging for 12 hours. Then carry out centrifugation, wash and filter the separated solid product with ethanol water solution with a volume ratio of 1:1, repeat several times, place the washed solid product in an oven at 60°C for 12 hours, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com