Method of preparing toner and toner prepared using the method

A technology of toner and stabilizer, applied in the field of toner preparation, can solve the problems of difficulty in controlling the size of latex particles, the reverse effect of surfactants, etc., and achieve the effect of good transfer ability and improved distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

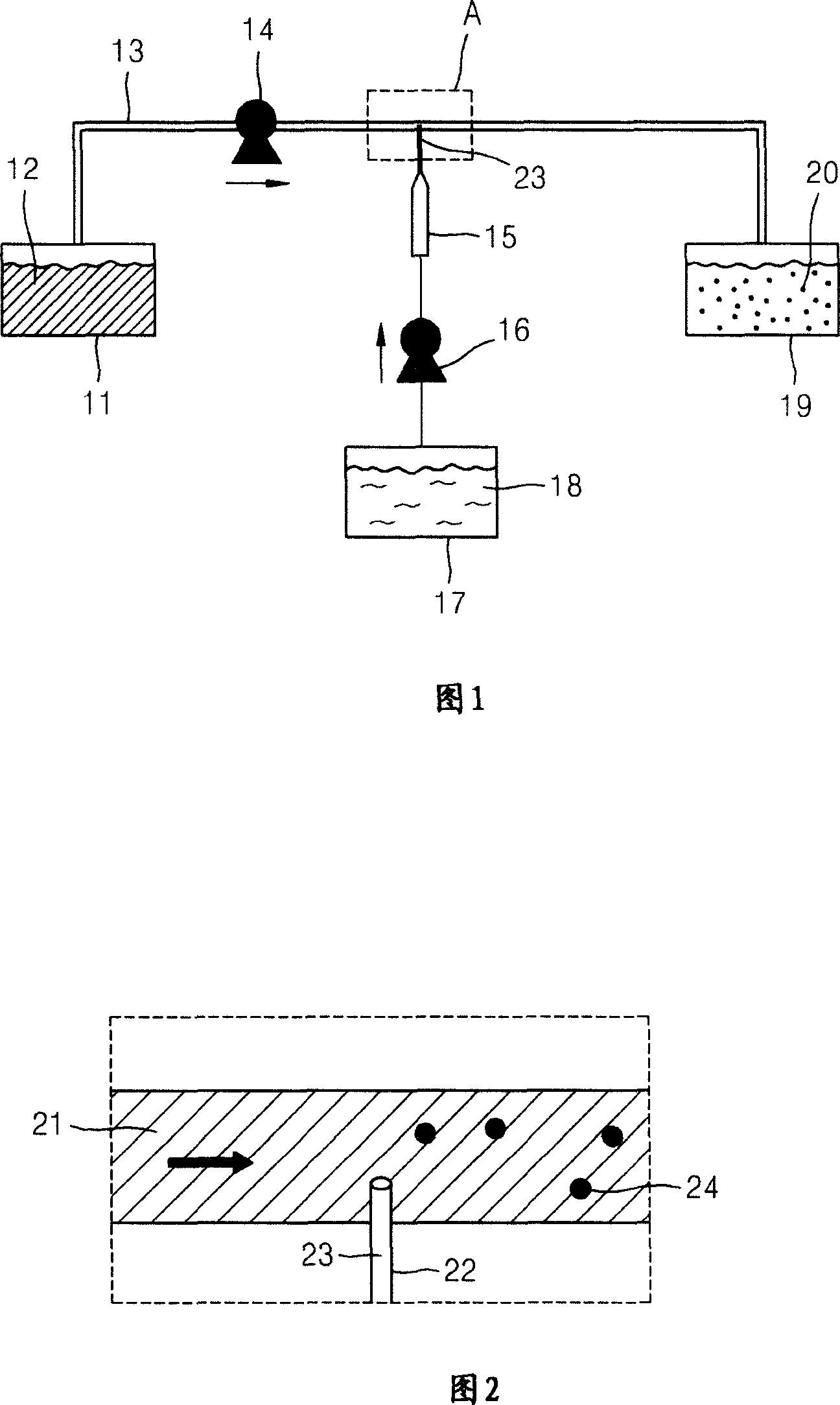

[0048] FIG. 1 is a schematic diagram showing a process of preparing a toner according to an embodiment of the present invention. FIG. 2 is an enlarged view of part A of FIG. 1 according to an embodiment of the present invention.

[0049] First, distilled water and a dispersant are injected into the first storage tank 11 and heated to 70-80° C. to prepare a stabilizer dispersion solution 12 . The pump 14 applies a predetermined pressure to the stabilizer dispersion solution 12 to move the stabilizer dispersion solution 12 to the reactor 19 through the pipe 13 .

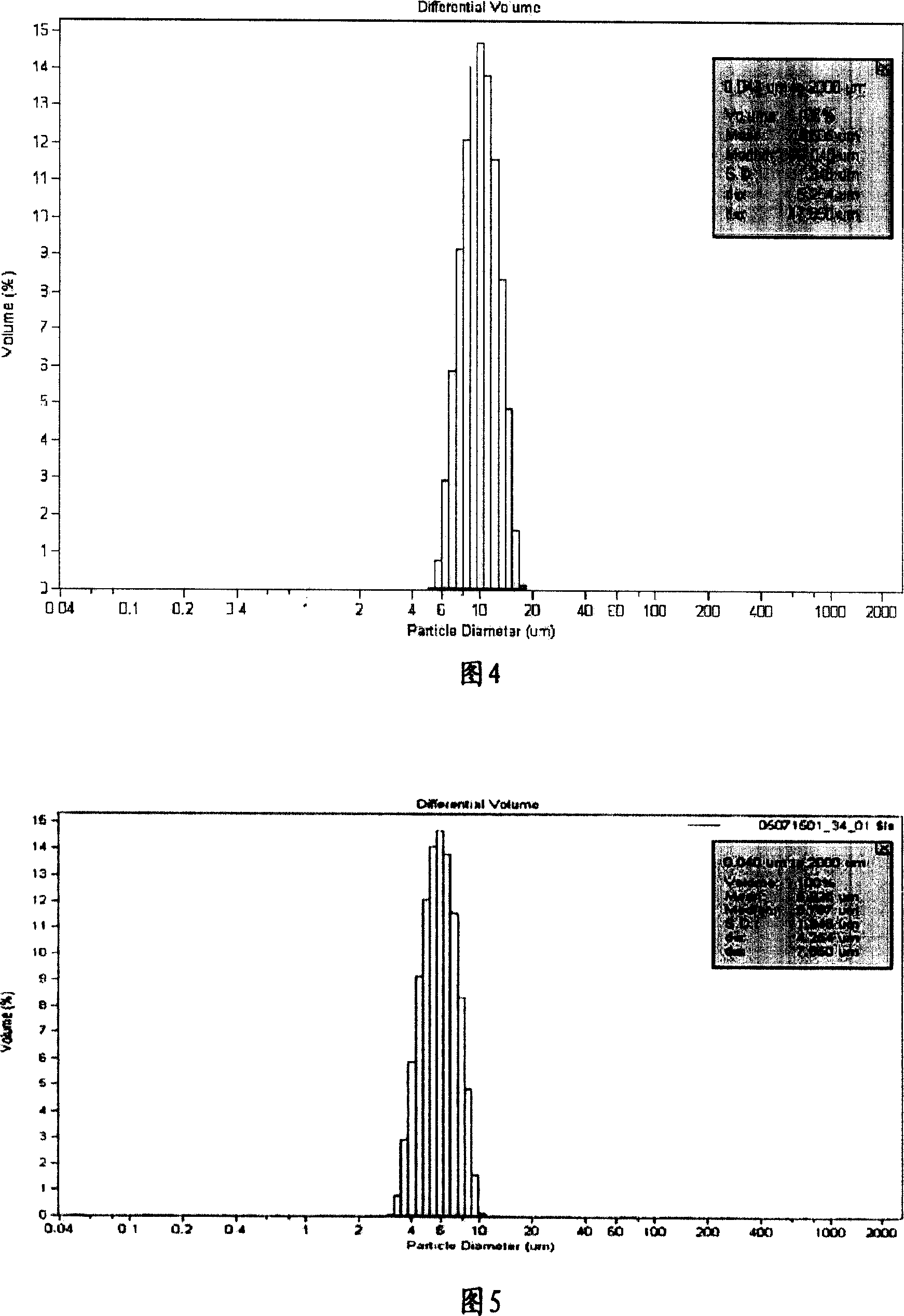

[0050] The toner composition 18 containing at least one polymerizable monomer, colorant and initiator is injected into the second storage tank 17 preheated to 70-85° C., and continuously injected into the preheated syringe 15 . A predetermined pressure is applied to the second storage tank 17 so that the toner composition 18 forms a droplet 24 through the syringe needle 22 . The diameter of the toner particles prepa...

example 1

[0082] Preparation of stabilizer dispersion solution

[0083] 400 g of distilled water and 4 g of PVA (molecular weight: 170,000) as a dispersant were injected into a 500 ml storage tank with a heat source and a stirrer. When the temperature rose to 70°C, the mixture was stirred to fully dissolve the dispersant. During the preparation of the core particles, the dispersant flowed continuously to the reactor through the tube while maintaining the temperature at 70°C.

[0084] Nucleus preparation

[0085] Introduce a monomer consisting of 148g styrene, 48g n-butyl acrylate and 14g acrylic acid and a chain transfer agent consisting of 0.02g n-dodecyl mercaptan, then add 10.5g carbon black, and use a bead mill (bead mill ) was stirred at 6000rmp for 5 minutes. Then, the beads were removed to prepare 105 g of monomer and pigment mixture. The temperature of the mixture was raised in a water bath at 70° C., then 5 g of paraffin was added, and stirred for 30 minutes to fully melt t...

example 2

[0089] A toner was prepared in the same manner as in Example 1, except that the temperature of the monomer storage tank was raised to 75° C. and a syringe needle having a diameter of 0.005 μm was used. The average diameter of the obtained toner particles was 5.8 µm, and the particle size distribution was very narrow.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com