Polarization maintaining fiber apodization grating production method

A manufacturing method and technology of polarization-maintaining fibers, which are applied in cladding fibers, optical waveguides, lasers, etc., can solve the problems of low grating side lobe suppression ratio, limited measurement range, accuracy, and detection sensitivity of peripheral measuring equipment, etc. Screening single, conducive to multiplexing, stable and reliable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

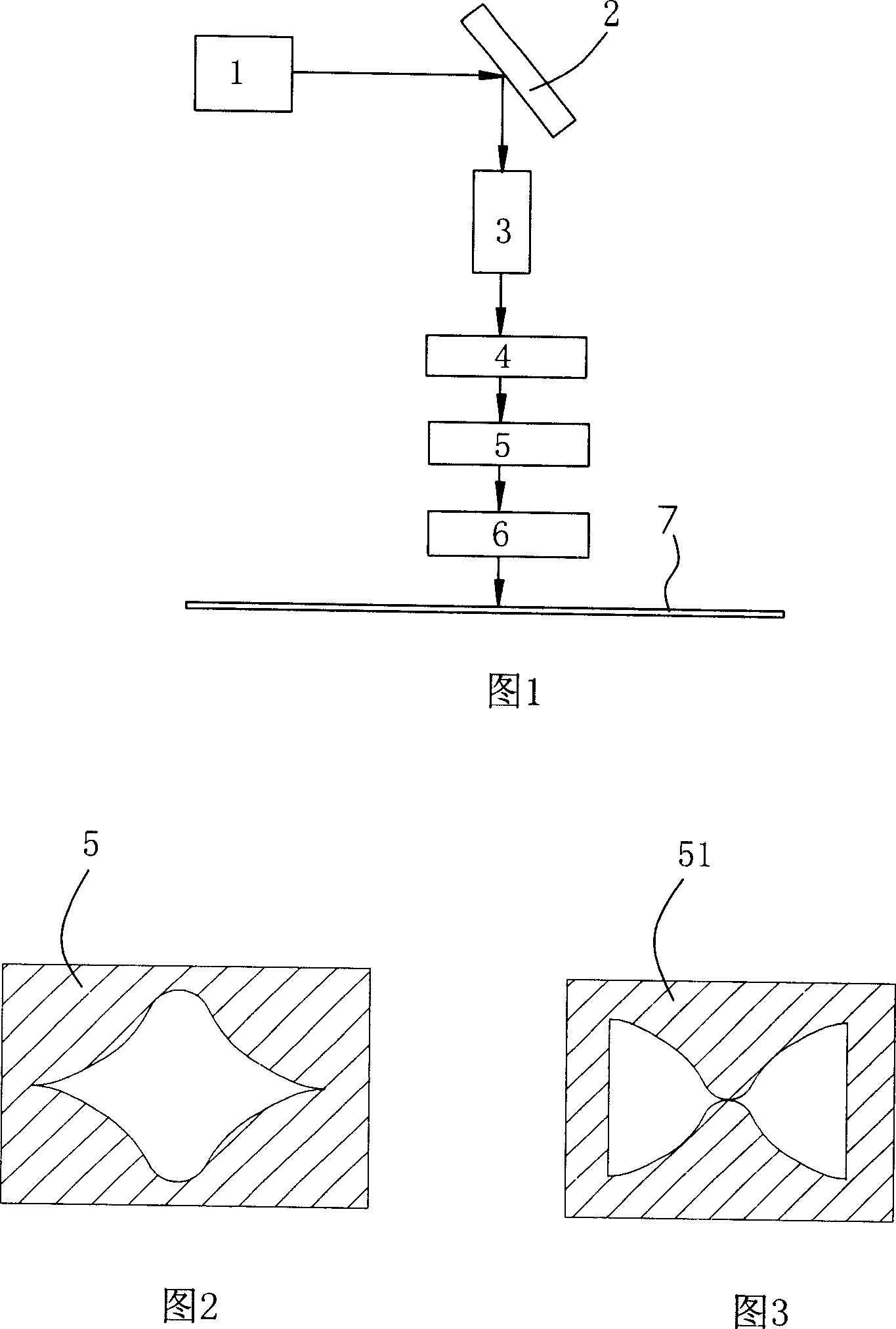

[0025] As shown in Figure 1, the production process is:

[0026] 1) Use krypton fluoride gas excimer laser 1 to generate 248nm ultraviolet light, adjust the spot size to 4mm×6mm through an adjustable diaphragm, and ensure that the spot line is parallel to the optical table;

[0027] 2) Refract the ultraviolet light generated by the excimer laser 1 at 90 degrees with the flat mirror 2, and ensure that the refracted light is also parallel to the optical table;

[0028] 3) Use a 5×10 ultraviolet light beam expander 3 to expand the ultraviolet light irradiated on the amplitude template 5, and the diameter of the spot after beam expansion is 50 mm;

[0029] 4) Use a cylindrical lens with a curvature radius of 101.7mm to longitudinally compress the spot of ultraviolet light;

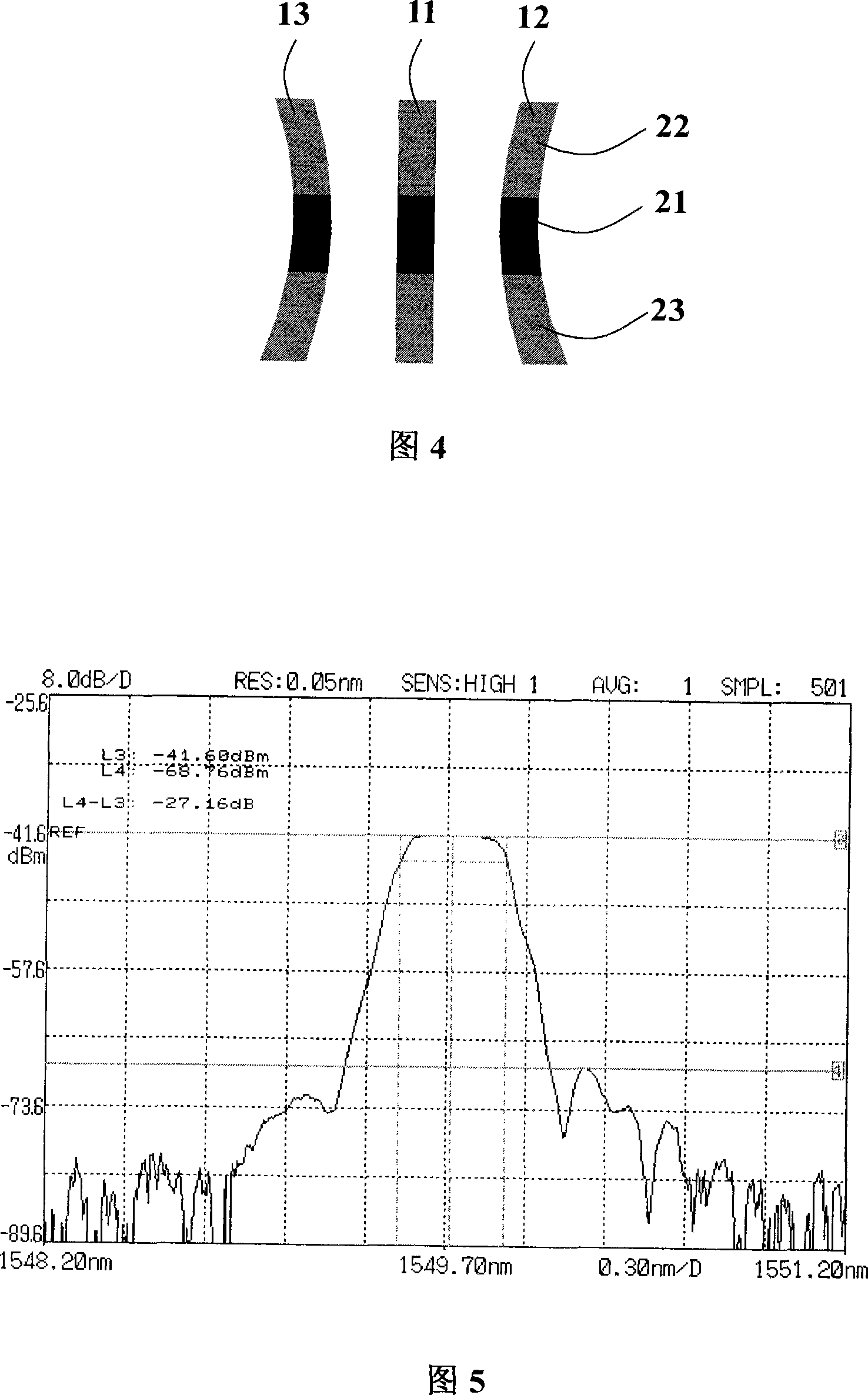

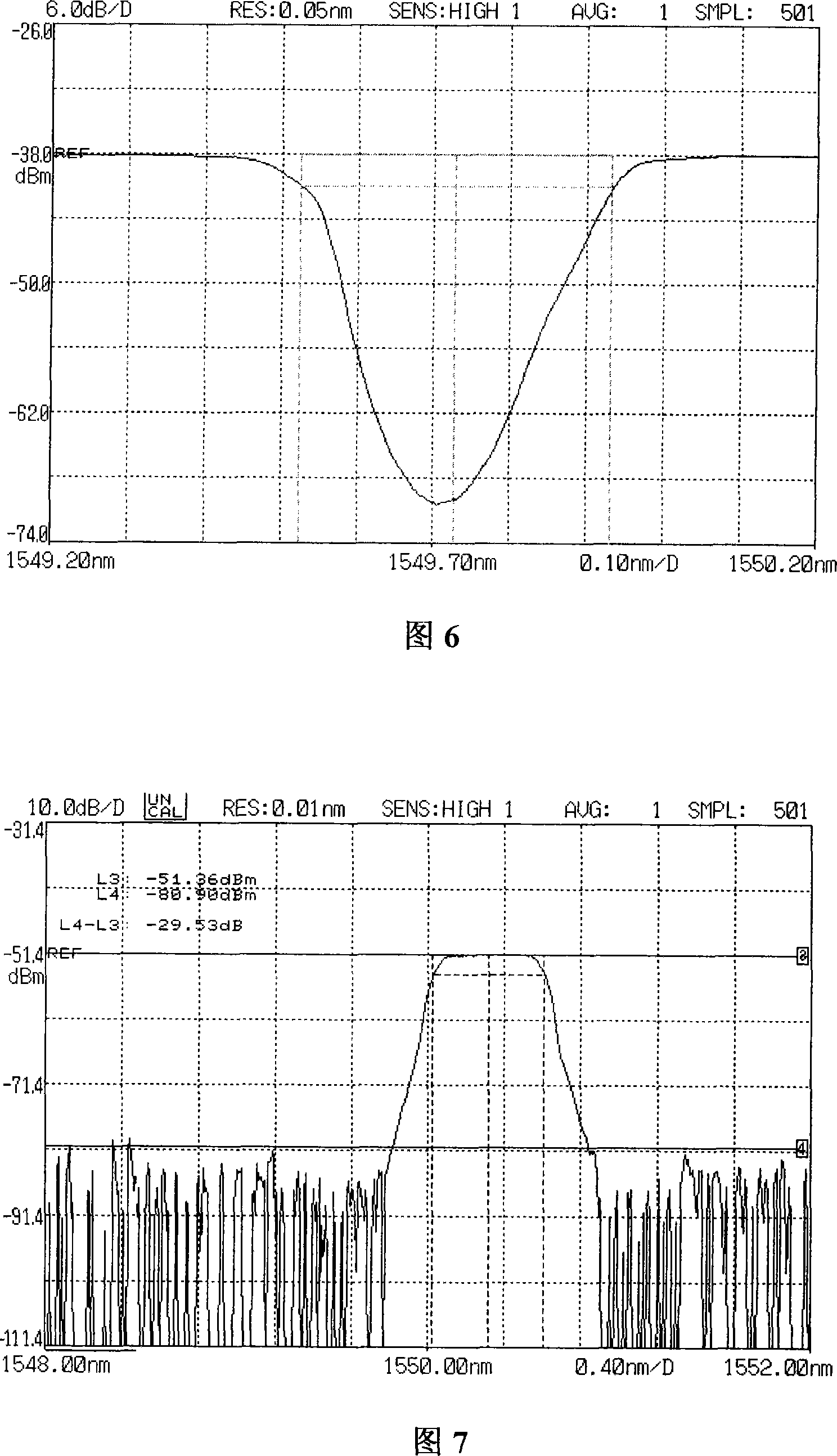

[0030] 5) Vertically illuminate the amplitude template 5 shown in Figure 2 with the compressed ultraviolet light. The amplitude template is made using the Hanning window function, and its internal window size...

Embodiment 2

[0038] The 248nm ultraviolet light refracted by the plane mirror 2 directly passes through the cylindrical lens with a radius of curvature of 101.7mm to longitudinally compress the ultraviolet light spot, and the rest of the process is the same as in embodiment 1, wherein the window size of the amplitude template is 5mm×11mm. Its reflection spectrum and transmission spectrum are shown in Fig. 7 and Fig. 8 . It can be seen from the figure that the bandwidth of the grating is 0.588nm, the sidelobe suppression ratio is 29.53dB, the central wavelength is 1550.320nm, and the reflectivity is 99.99%.

[0039] The invention can produce a polarization maintaining fiber apodization grating with a bandwidth less than 1.0nm and a side lobe suppression ratio greater than 25dB within the wavelength range of 860nm-1610nm, and is mainly used in pump amplifiers and polarization maintaining fiber sensors.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Center wavelength | aaaaa | aaaaa |

| Bandwidth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com