Multilayer printed circuit board

A multi-layer printing and circuit board technology, which is applied in the manufacture of multi-layer printed circuit boards and the field of multi-layer printed circuit boards, can solve the problems that the mask and the laser device cannot match the position of the substrate, and the electrical connection cannot be obtained. , to achieve the effect of improving the conductivity and adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

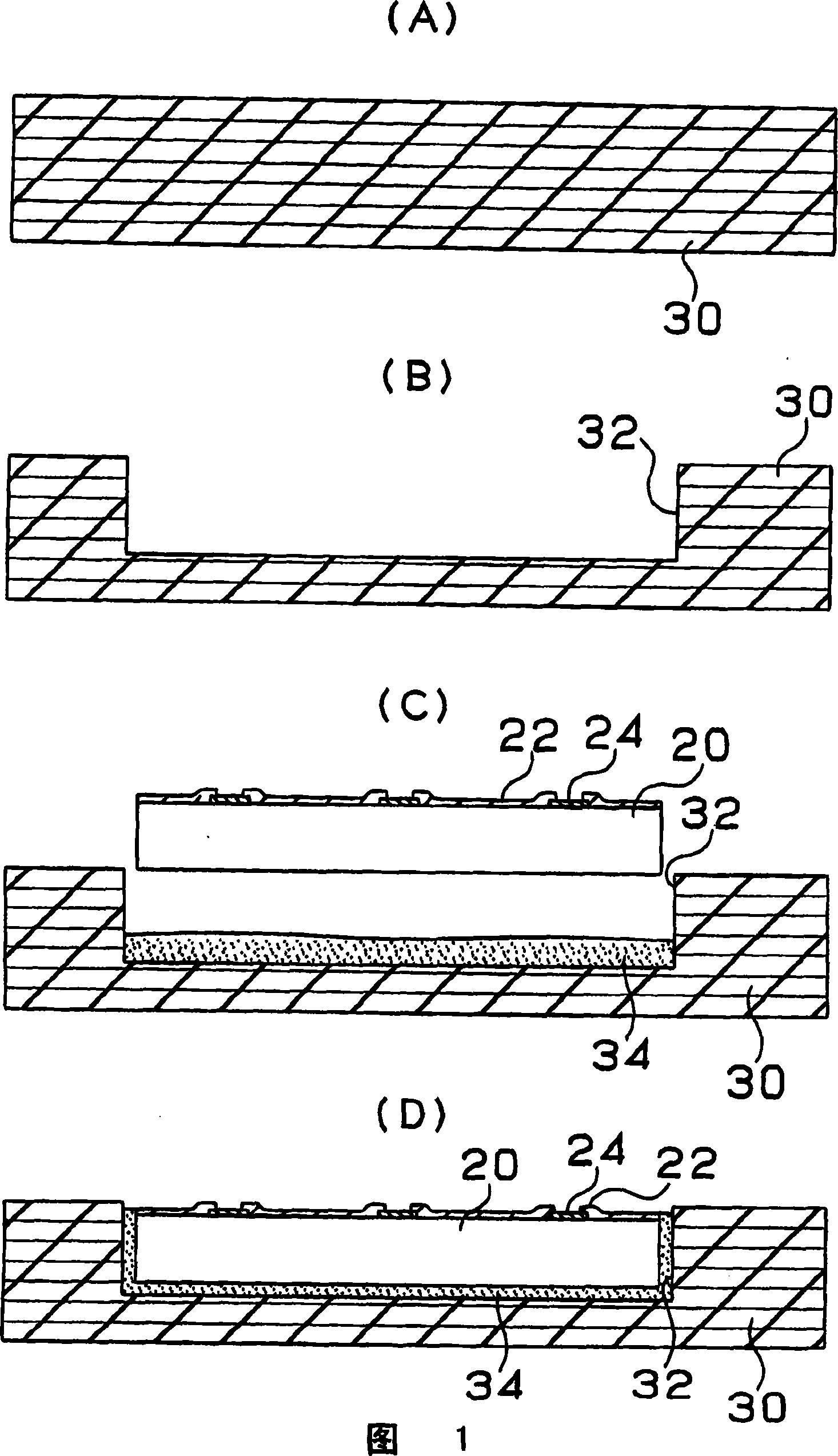

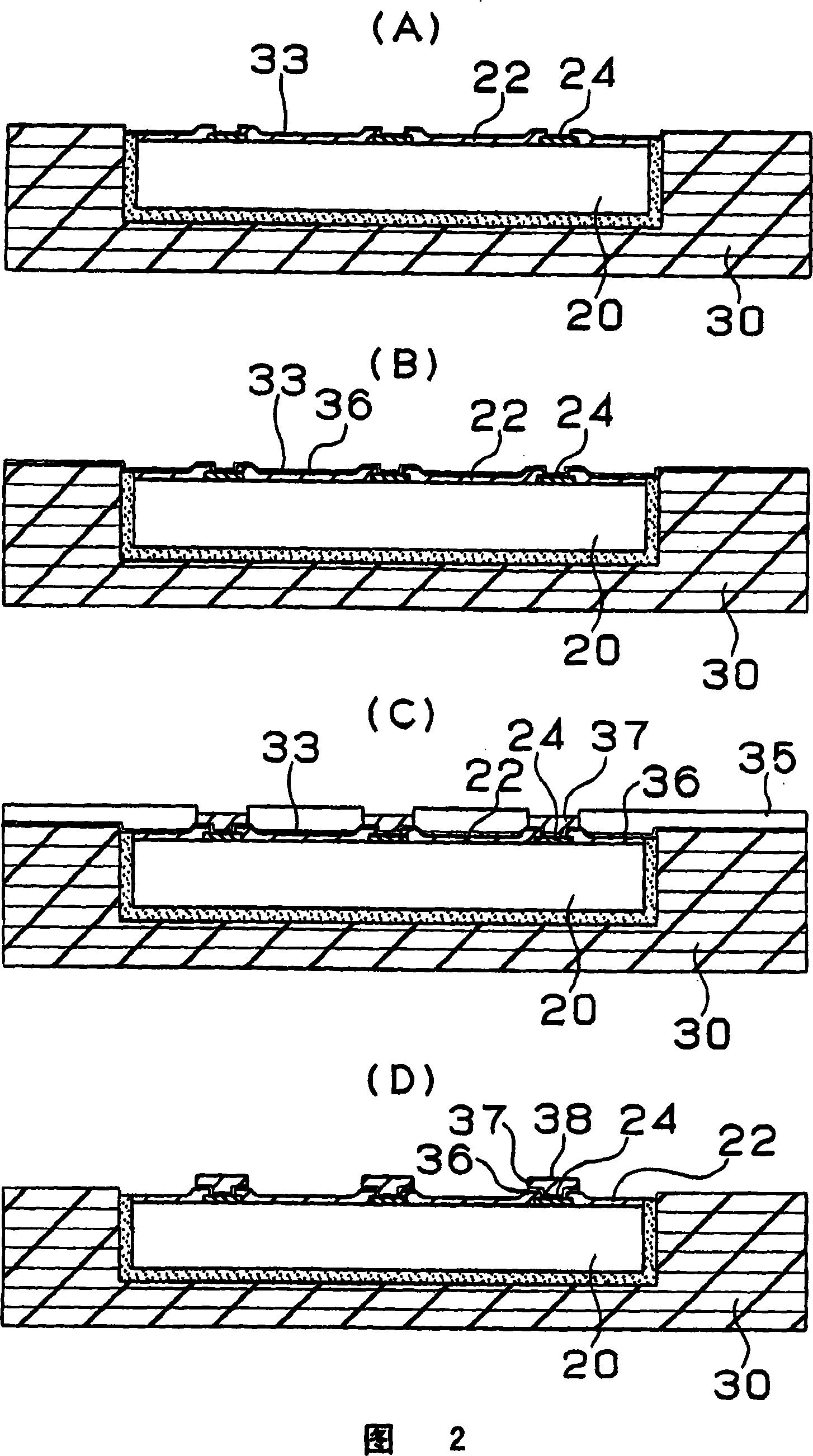

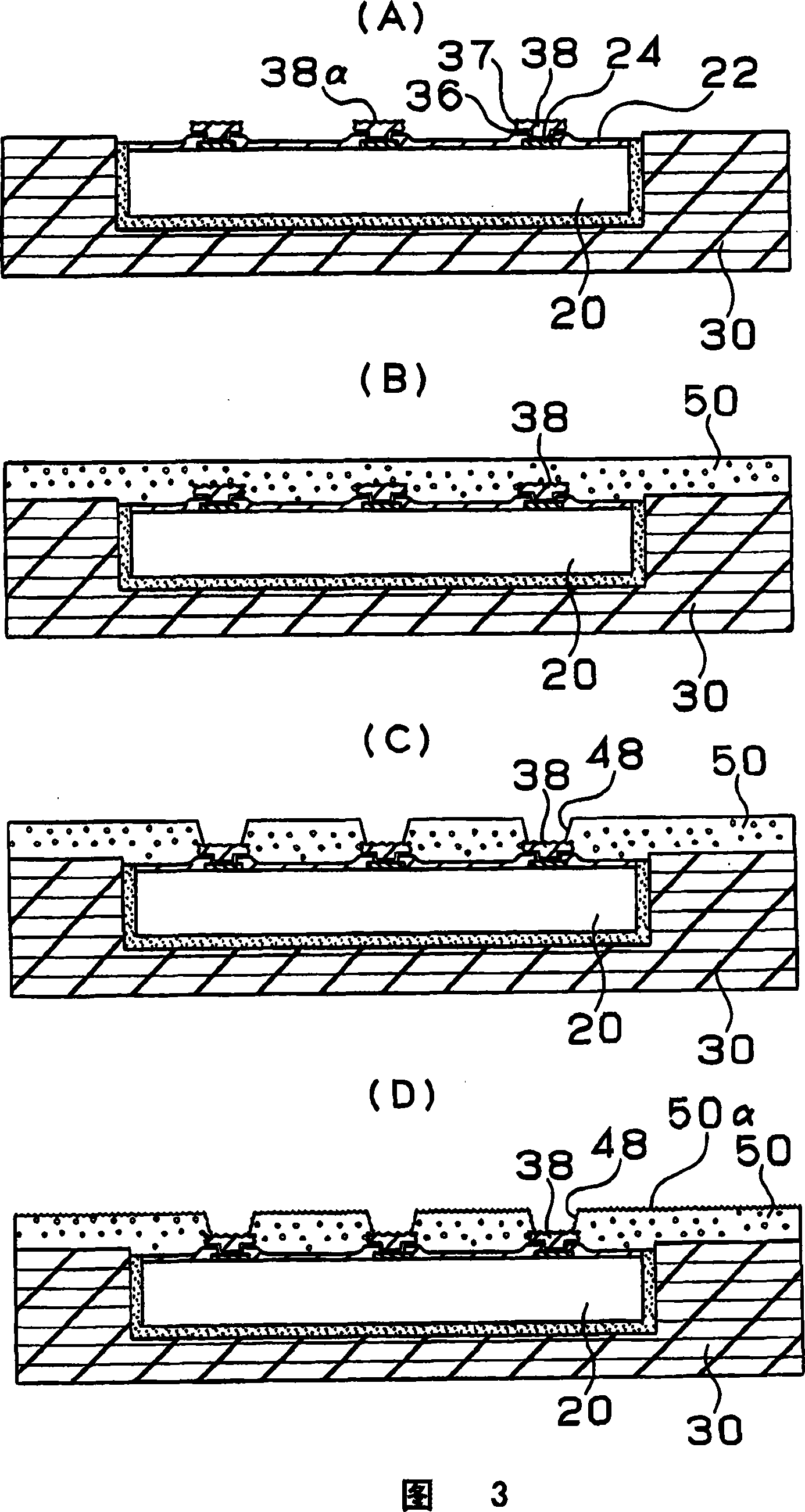

[0104] First, the configuration of the multilayer printed wiring board according to the first embodiment of the present invention will be described with reference to the cross section of the multilayer printed wiring board 10 shown in FIG. 6 .

[0105] The multilayer printed circuit board shown in FIG. 6 is composed of a core substrate 30 accommodating an IC chip 20 , an interlayer resin insulating layer 50 , and an interlayer resin insulating layer 150 . The through hole 60 and the conductive circuit 58 are formed on the interlaminar resin insulating layer 50 , and the through hole 160 and the conductor circuit 158 are formed on the interlaminar resin insulating layer 150 .

[0106] The IC chip 20 is covered with a passivation film 24 , and a die pad 24 constituting an output terminal is arranged in an opening of the passivation film 24 . Over the die pad 24 made of aluminum, a transition layer 38 is formed. The transition layer 38 is composed of three layers of the first ...

Embodiment 2

[0208] Next, the structure of the multilayer printed wiring board according to the second embodiment of the present invention will be described with reference to the cross section of the multilayer printed wiring board shown in FIG. 18 .

[0209] The multilayer printed circuit board 210 shown in FIG. 18 is composed of a core substrate 230 accommodating an IC chip 220 , an interlayer resin insulating layer 250 , and an interlayer resin insulating layer 350 . The through hole 260 and the conductive circuit 258 are formed on the interlayer resin insulating layer 250 , and the through hole 360 and the conductive circuit 358 are formed on the interlayer resin insulating layer 350 .

[0210] A passivation film 224 is covered on the IC chip 220 , and a die pad 224 constituting an output terminal and a positioning mark 223 are arranged in an opening of the passivation film 224 . On top of the pad 224, a transition layer 238 consisting mainly of copper is formed.

[0211] On the int...

Embodiment 3

[0243] Next, the structure of the multilayer printed wiring board according to the third embodiment of the present invention will be described with reference to the cross section of the multilayer printed wiring board 410 shown in FIG. 26 .

[0244] The multilayer printed circuit board 410 shown in FIG. 26 is composed of a core substrate 430 accommodating an IC chip 420 , an interlayer resin insulating layer 450 , and an interlayer resin insulating layer 550 . The through hole 460 and the conductive circuit 458 are formed on the interlayer resin insulating layer 450 , and the through hole 560 and the conductive circuit 558 are formed on the interlayer resin insulating layer 550 .

[0245] An IC protective film (passivation+polyimide) 422 is overlaid on the IC chip 420 , and an aluminum die pad 424 constituting an output terminal is arranged in an opening of the IC protective film 422 . On the surface of the die pad 424, an oxide coating film 426 is formed. On the die pad 424,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com