Automatic homogeneous sprinkling device for matrix material-laying and sprinkling machine

A water spraying device, water spraying machine technology, applied in the direction of spraying device, spraying device, application, etc., can solve the problems of too fast showering water, waste recycling, affecting the quality of production line operation, etc., and achieve the effect of convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

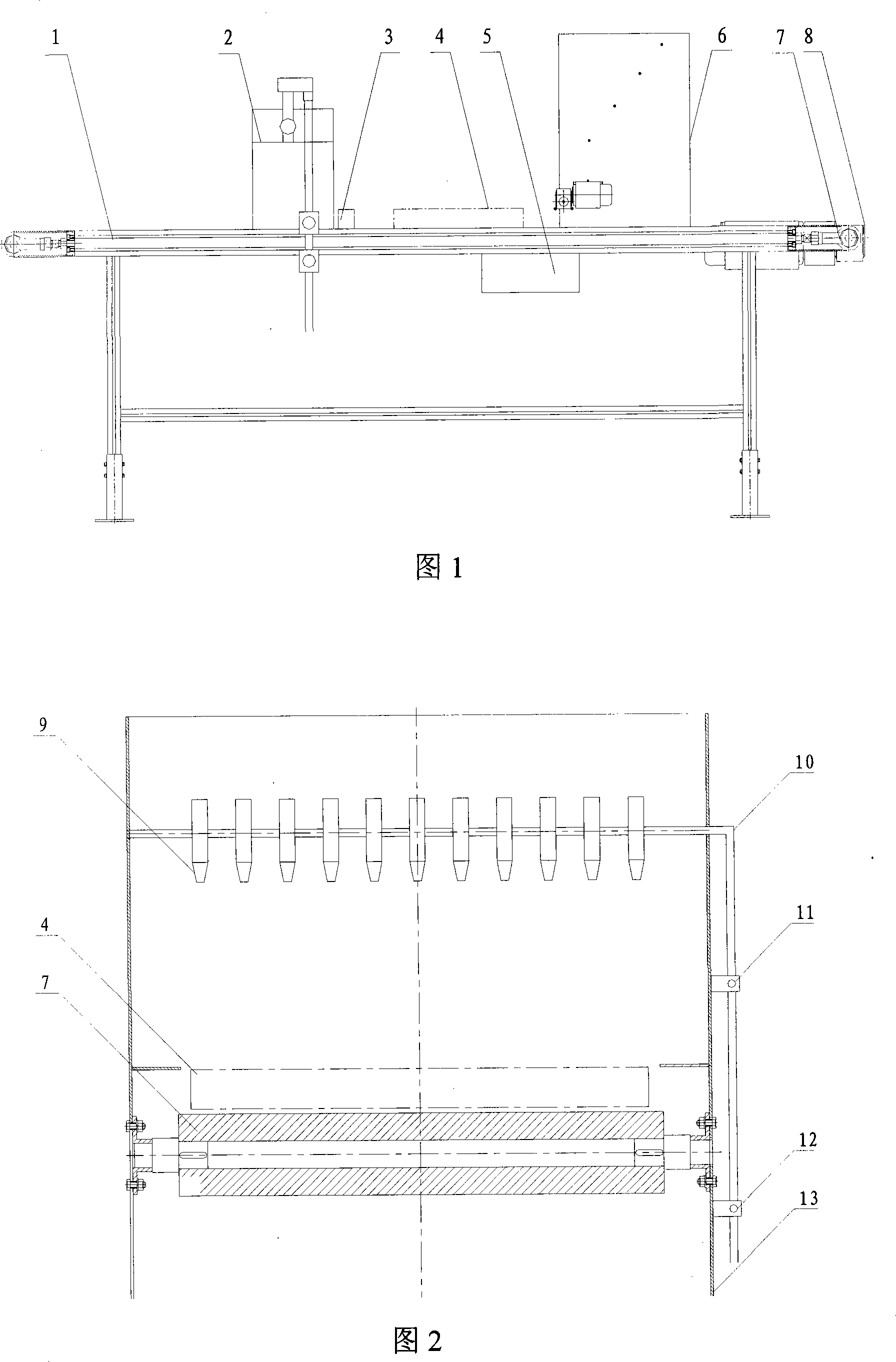

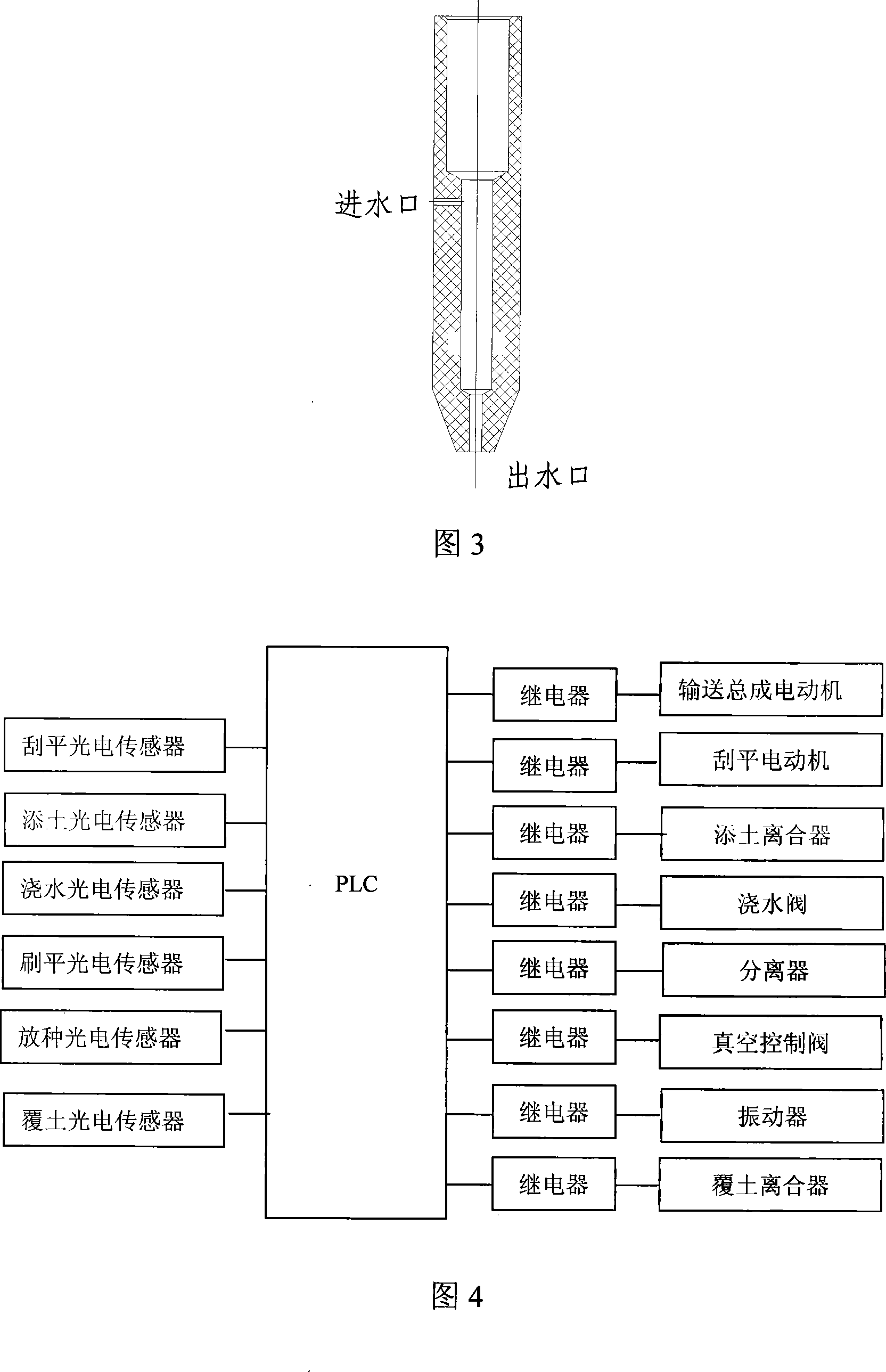

[0015] As shown in Figures 1 and 2, the automatic uniform water spraying device used in the substrate coating water spraying machine has a frame 1, on which there are a water spraying part 2, an infrared photoelectric sensor 3, a coating part 6, The conveyor belt assembly 7, the conveyor belt assembly 7 is driven by the motor 8, the tray 4 is driven by the conveyor belt assembly 7, the water spraying component 2 has a box 13, and the box 13 is provided with a water pipe 10, and the water pipe 10 is provided with The dripper 9, solenoid valve 12, the device is controlled by the controller (5).

[0016] The invention adopts an infrared light sensor to induce an electric signal and a control method of a delay relay. When the plug enters the covering area, the covering operation is automatically carried out first. When the coating is completed, when the plug enters the water spraying area, the photoelectric sensor sends out an electrical signal to control the solenoid valve to open, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com