Method of preparing corn polypeptide with rough material of zein

A technology of zein and corn polypeptide, which is applied in plant protein processing, etc., can solve problems such as complicated operation process, difficult to accurately grasp the pH of the process process, toxic and harmful substances, etc., and achieve simplified enzymatic hydrolysis production process, good quality and efficacy , the effect of high protein content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

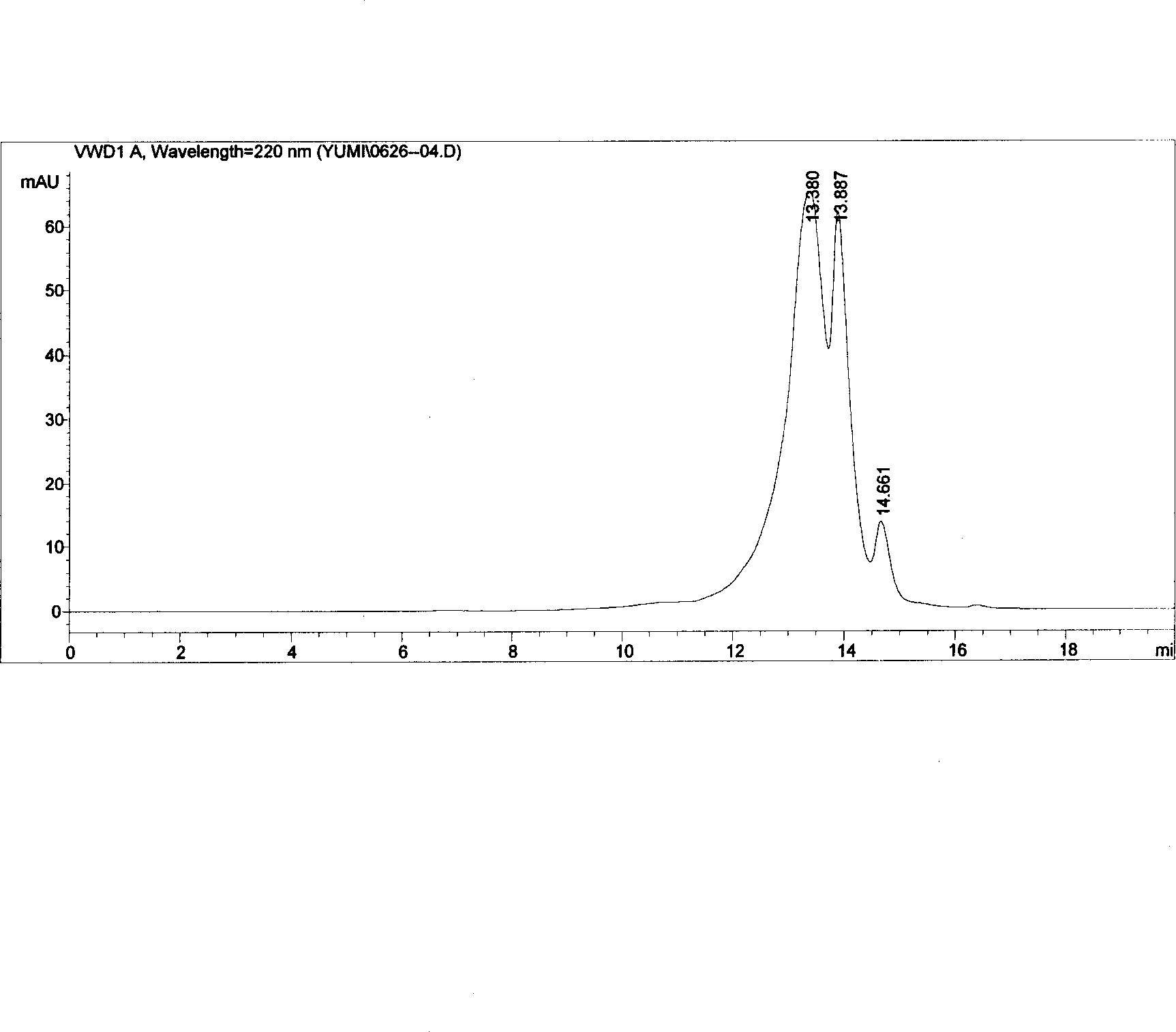

Image

Examples

Embodiment 1

[0019] First, take zein powder with a total nitrogen content greater than or equal to 14% according to the ratio of material to liquid weight ratio of 1:15, put it into distilled water or pure water, stir evenly, and adjust its pH value with potassium hydroxide reagent. 7.5, and place the solution in a thermostat at 35° C. for 25 minutes, and keep stirring to fully dissolve the zein in it to obtain an aqueous solution of zein. Next, take the Alcalase alkaline protease whose enzyme activity unit is 200,000 U / g and whose weight accounts for 1% of the zein powder, and add it to the above-mentioned zein aqueous solution, and heat up to 60° C. During the enzymatic hydrolysis, stirring was continued, and the enzymatic hydrolysis time was maintained for 4 hours to obtain a zein enzymatic hydrolyzate. Then, the above-mentioned zein enzymatic hydrolysis solution was heated to boiling state, kept for 5 minutes to inactivate the enzyme activity, and when it was cooled to 80° C., coarse f...

Embodiment 2

[0021] First, take zein powder with a total nitrogen content greater than or equal to 14% according to the ratio of material to liquid weight ratio of 1:18, put it into distilled water or pure water, stir evenly, and adjust its pH value with potassium hydroxide reagent. 7.8, and place the solution in a thermostat at 40°C for 30 minutes, and keep stirring to fully dissolve the zein in it to obtain an aqueous solution of zein. Secondly, take the Alcalase alkaline protease whose enzyme activity unit is 200,000 U / g and whose weight accounts for 2% of zein powder, add it to the above-mentioned zein aqueous solution, and heat up to 55° C. During the enzymatic hydrolysis, stirring was continued, and the enzymatic hydrolysis time was maintained for 5 hours to obtain a zein enzymatic hydrolyzate. Then, the above-mentioned zein enzymatic hydrolysis solution was heated to boiling state, kept for 8 minutes to inactivate enzyme activity, and when it was cooled to 70° C., coarse filtration ...

Embodiment 3

[0023] First, take zein powder with a total nitrogen content greater than or equal to 14% according to the ratio of material to liquid weight ratio of 1:20, put it into distilled water or pure water, stir evenly, and adjust its pH value with potassium hydroxide reagent. 8.0, and the solution was kept in a thermostat at 45° C. for 35 minutes, and kept stirring to fully dissolve the zein in it to obtain an aqueous solution of zein. Secondly, take the Alcalase alkaline protease whose enzyme activity unit is 200,000 U / g and whose weight accounts for 3% of the zein powder, add it to the above-mentioned zein aqueous solution, and heat up to 50° C. During the enzymatic hydrolysis, stirring was continued, and the enzymatic hydrolysis time was maintained for 6 hours to obtain a zein enzymatic hydrolyzate. Then, the above-mentioned zein enzymatic hydrolysis solution was heated to boiling state, kept for 10 minutes to inactivate the enzyme activity, and when it was cooled to 75° C., coar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com