Method of heating and controlling cabinet-type electric furnace

A box-type electric furnace, heating control technology, applied in the direction of heat treatment process control, furnace, heat treatment furnace, etc., can solve the problems of mechanical wear, bearing parts becoming waste products, contact adhesion, etc., to eliminate reactive power loss and improve utilization rate , adjust the delicate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

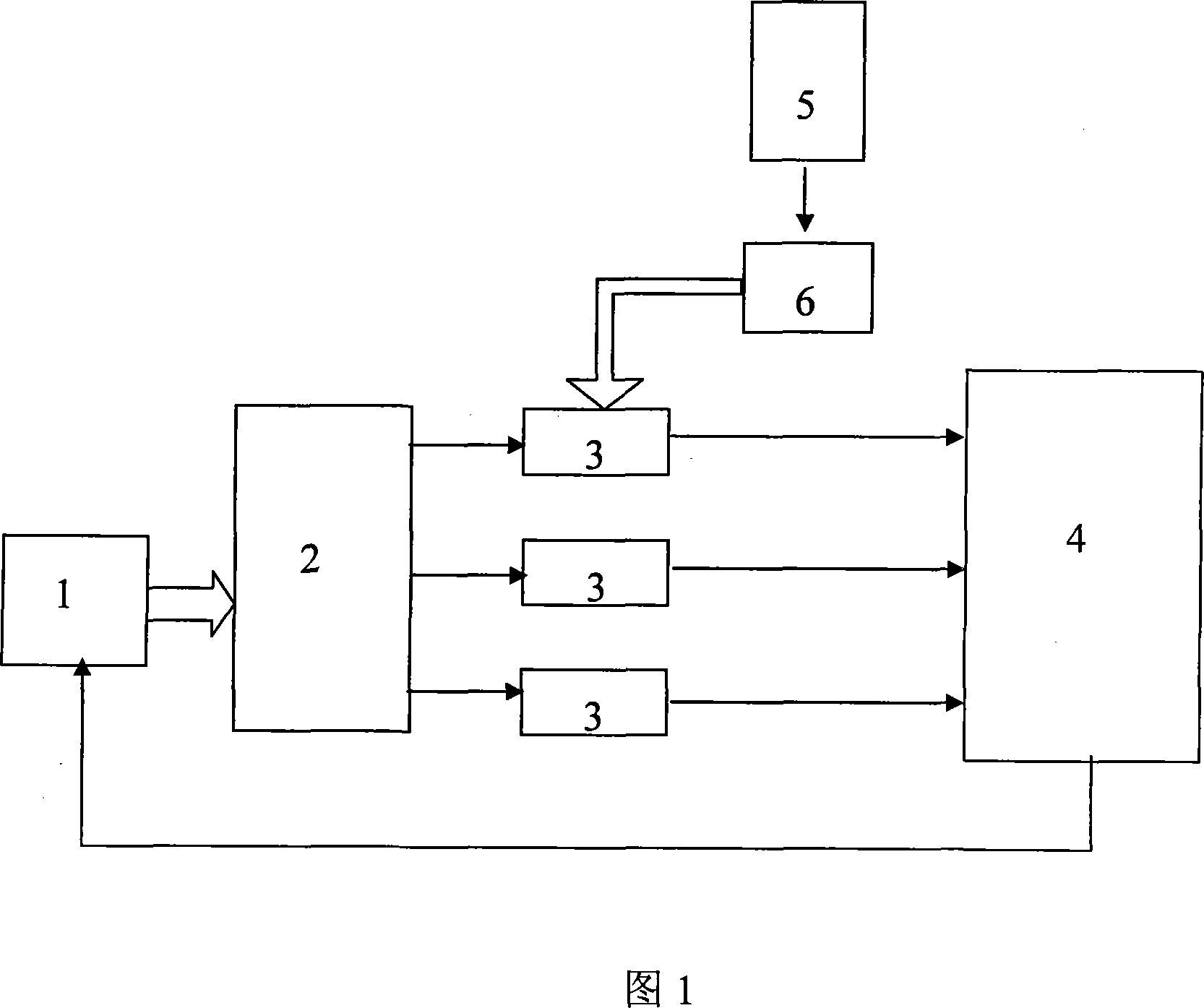

[0014] The present invention is described in further detail below in conjunction with accompanying drawing:

[0015] As shown in Figure 1, the circuit of the heating control method of a kind of box-type electric furnace of the present invention is mainly composed of PID temperature controller 1, pulse trigger circuit 2, AC solid state relay 3, industrial box-type resistance furnace 4, three-phase AC power supply 5 Composed of furnace door safety device 6. Among them, the PID temperature controller 1 adopts the SR253 PID regulator produced by Japan Shimaden Instrument Co., Ltd.; the pulse trigger circuit 2 adopts the ZAC type cycle controller; the AC solid state relay 3 adopts the SSR type AC solid state relay; the three-phase AC power supply 5 is an industrial A power supply with a frequency of 50 Hz and a rated voltage of 380 volts; the furnace door safety device 6 is mainly composed of an electronic crystal switch or an electromechanical fiber and a small contactor. The dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com