LED lens

A LED lens and lens technology, applied in lighting and heating equipment, electrical components, circuits, etc., can solve the problems of high power LED heat generation, poor LED contact, and affecting light output effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

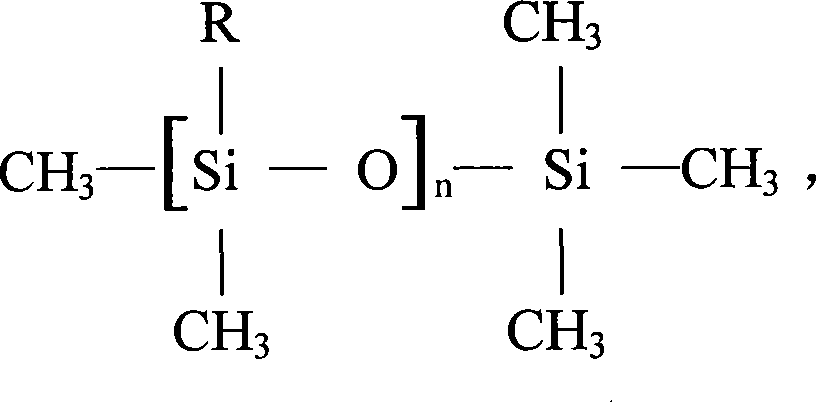

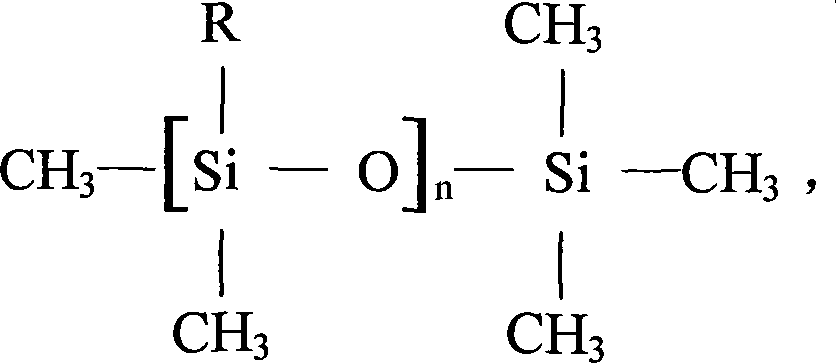

[0010] Embodiments of the present invention are described below, and in addition, the silicone resin used in the embodiments described below is a high-power LED lens manufactured by the method described below.

[0011] Mix 20 parts by weight of a cage-type silicone resin having methylpolyvinyl groups on all silicon atoms, 60 parts by weight of dicyclopentyl diacrylate, and 2.0 parts by weight of 1-hydroxycycloethylbenzophenone as a photopolymerization initiator , to obtain a transparent silicone resin composition.

[0012] Firstly, liquid transparent silicone resin is injected into the injection molding machine, and it is returned to the furnace at a high temperature of about 250°C, cooled and solidified to form a lens shape. Then superimpose the LED base with the chip on the silicone lens, preheat and mix the glue, and remove the air in the gap between the LED base with the chip and the silicone lens to make it a vacuum state. Heating back to the furnace to a high temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com