Control method for normally riveted curved member

A control method and riveting technology, applied in the direction of digital control, electrical program control, manufacturing tools, etc., can solve the problems of large normal verticality error, low degree of automation, unstable quality, etc., and achieve small normal verticality error, The effect of improving production efficiency and improving riveting quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

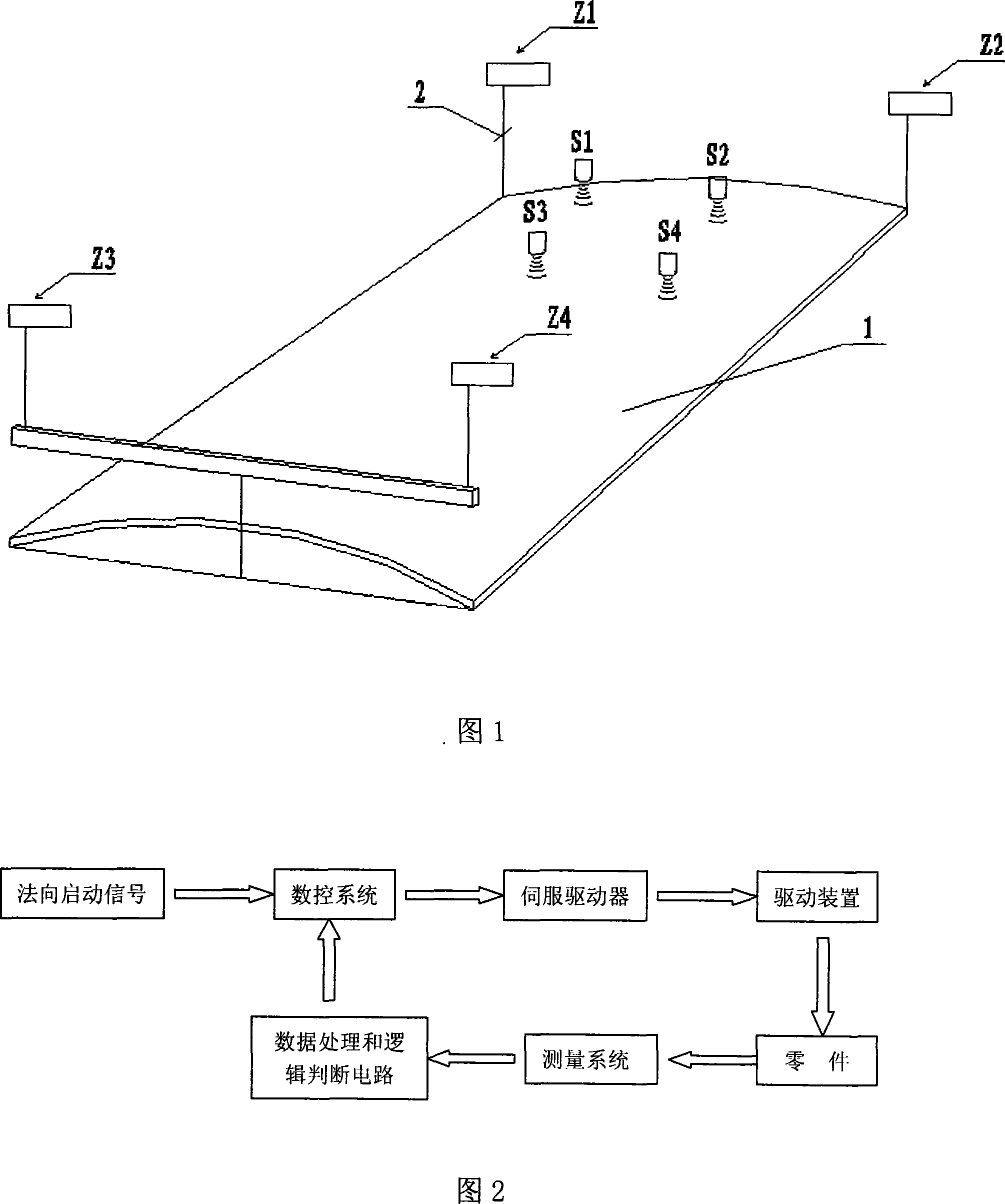

[0018] See Figure 1. Due to the larger radius of the aircraft skin, the arc variation within a smaller range of the skin is smaller. If you want to detect whether the normal of a certain point is vertical, you can use a plane to horizontally cut four points with equal margins centered on this point. If these four points are just on this horizontal plane, that is, the height of these four points The difference is zero. It can be considered that the normal of the detected point is in the vertical position, that is, in the normal position. The smaller the margins between these four points, the greater the resulting accuracy, but the more difficult it is to detect and control. In practical application, the edge distance selected in this embodiment is four points of 200×200 mm, and the two can be considered at this distance. According to the above theory, measure the distance of four points on the margin of 200×200mm, feed back the measured data to the control system for process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com