Light-emitting element and method for manufacturing light-emitting element

一种发光元件、制造方法的技术,应用在半导体/固态器件制造、制造工具、电气元件等方向,能够解决Au-Sn系焊料层剥离问题不容易获得解决等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

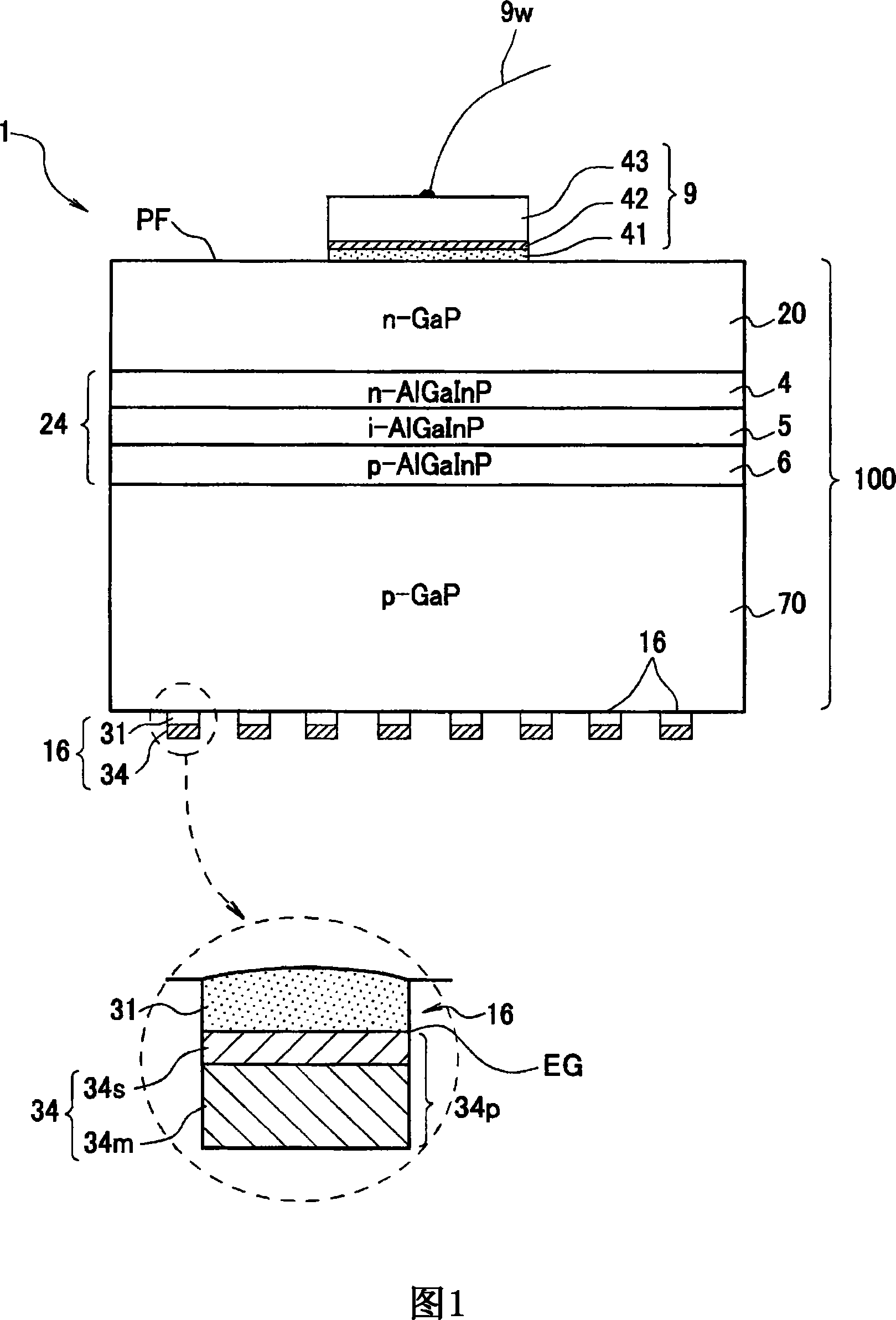

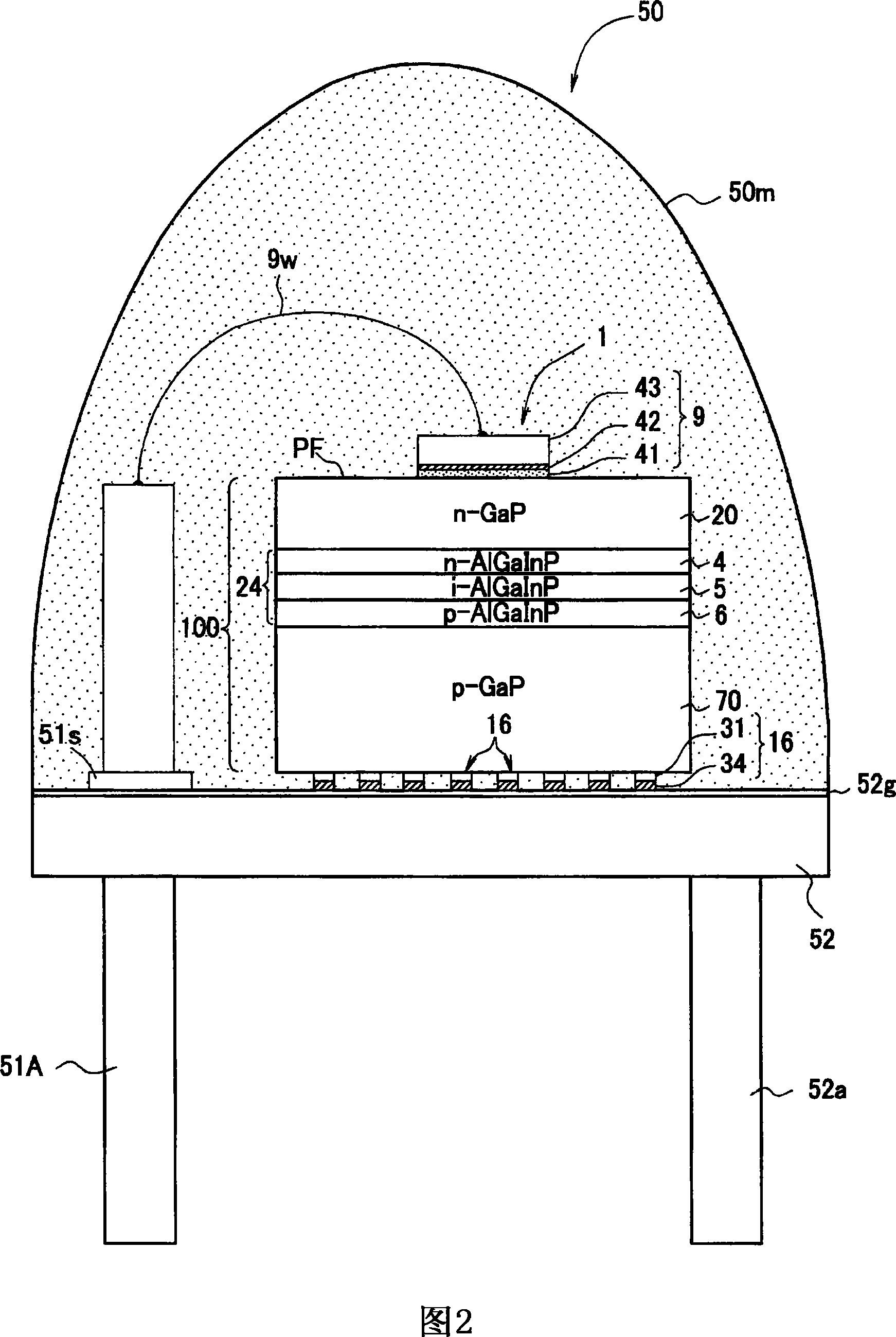

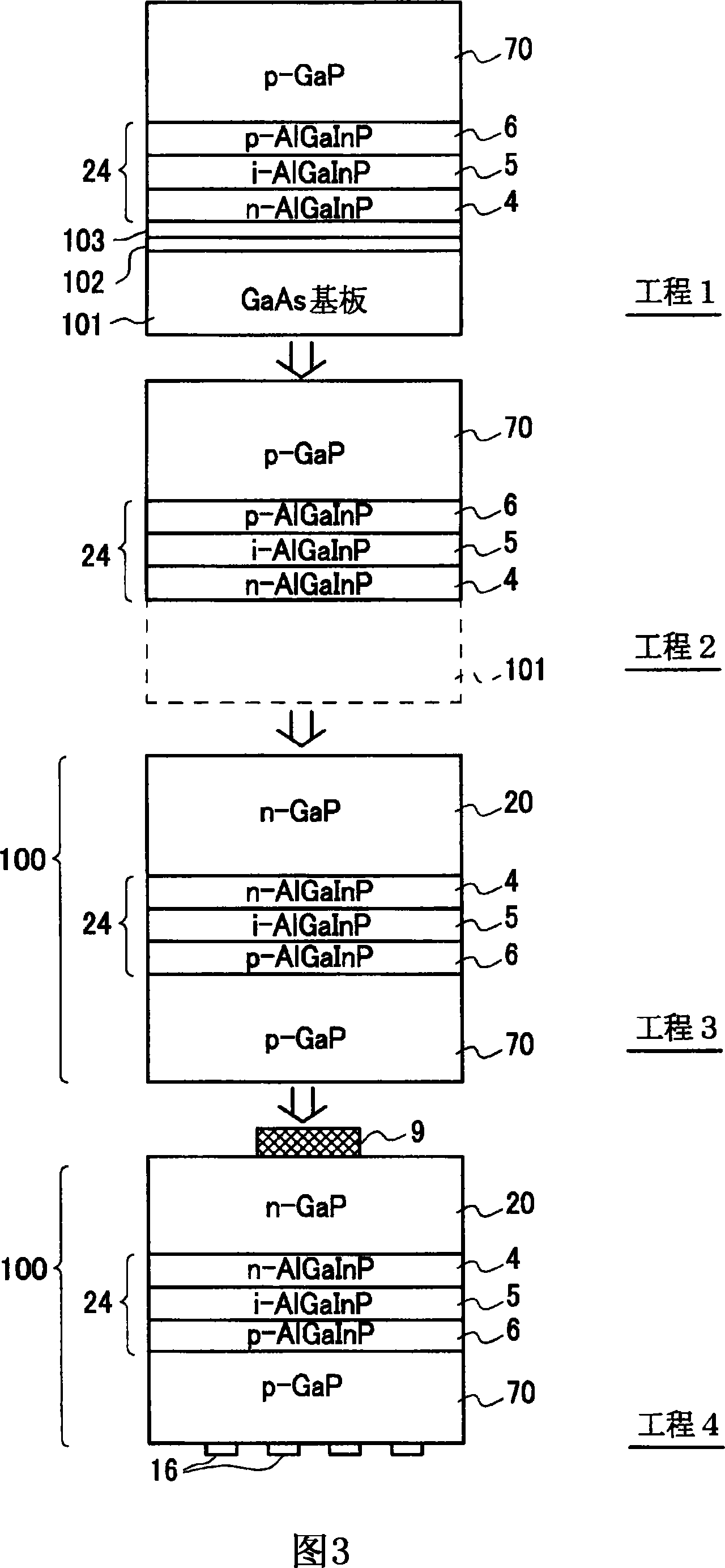

[0066] Hereinafter, embodiments of the method of manufacturing a light-emitting element according to the present invention will be described with reference to the drawings. Fig. 1 is a schematic conceptual diagram of a light-emitting element to which the present invention is applied. The light-emitting element 1 has the main surface on the light extraction surface side of the compound semiconductor layer 100 having the light-emitting layer portion 24 as the first main surface, and the main surface on the opposite side as the second main surface. The first electrode 9 and the second electrode 16 are respectively formed on the second main surface. The second electrode 16 has a bonding alloyed layer 31 and a solder layer 34, the bonding alloyed layer 31 is provided in contact with the second main surface of the compound semiconductor layer 100 to reduce the bonding resistance with the compound semiconductor layer 100, the The solder layer 34 is used to connect the bonding metal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com