Vanadium-containing sewage treatment method

A treatment method and wastewater technology, which is applied in the field of wastewater treatment containing chromium and ammonia nitrogen, can solve the problems of waste of raw materials and drugs, heavy processing workload, and substandard products, and achieve high-efficiency recycling, low equipment requirements, and simple and easy methods Use the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

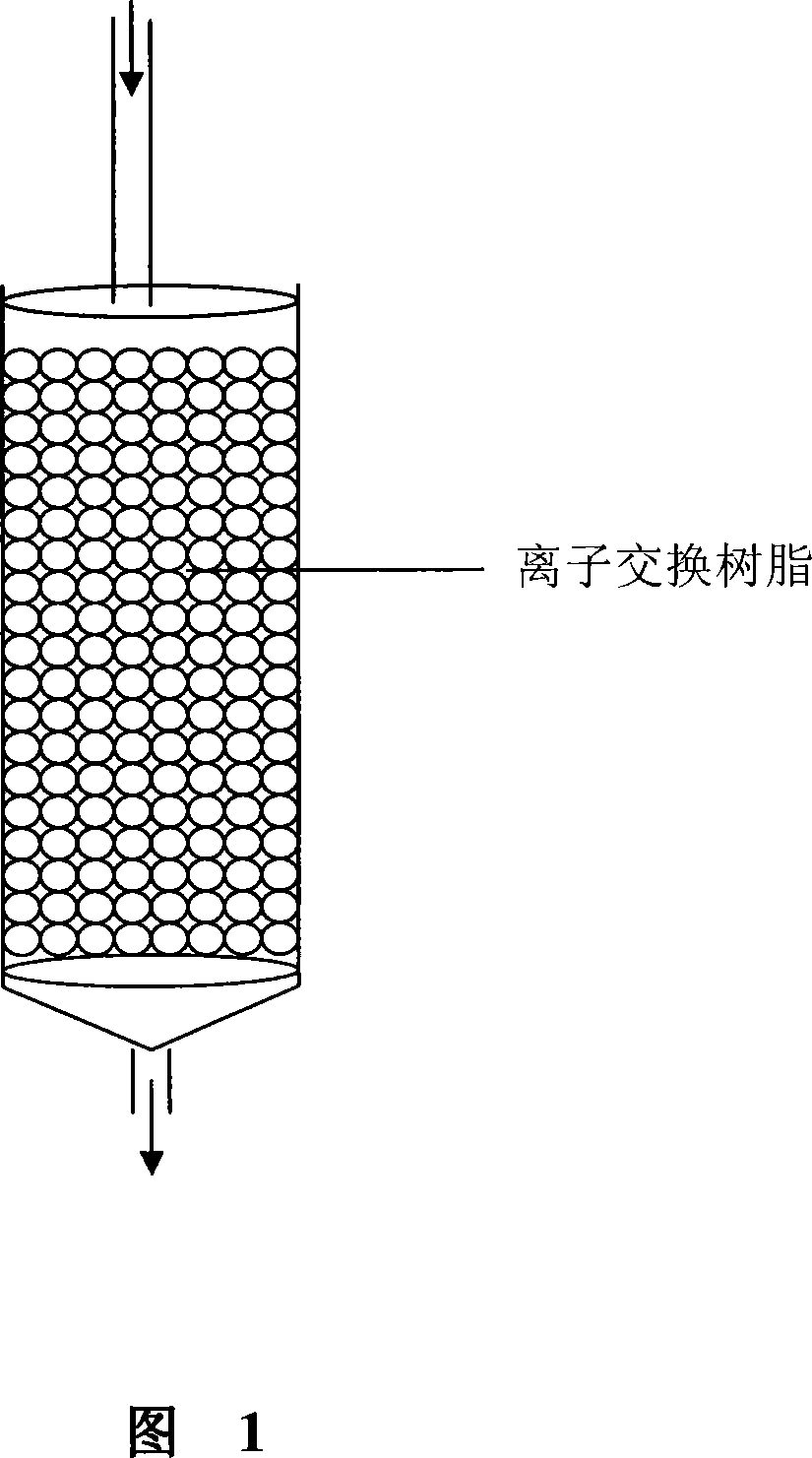

Image

Examples

Embodiment 1

[0025] Embodiment one inventive method resin screening test

[0026] Commercially available anion exchange resins such as IRA96RF, 717 (D201×7), 711 (D201×4), D301, and D901 were used for pre-testing.

[0027] 100g IRA96RF, 717, 711, D301, D901 were used for static adsorption test respectively, and 1g.L was adsorbed under the respective optimal adsorption conditions -1 The vanadium liquid, when the adsorption rate reaches 98%, respectively use 3.0h, 3.5h, >5.0h, >5.0h, >5.0h.

[0028] Use 100g IRA96RF, 717, 711, D301, D901 to carry out the timed adsorption test respectively, and absorb 1g.L under the respective optimal adsorption conditions -1 The amount of vanadium adsorbed in the vanadium liquid was 7.3g, 7.3g, 4.7g, 4.7g, 4.8g after 3 hours.

[0029] Use 100g IRA96RF, 717, 711, D301, D901 to dynamically adsorb Cr respectively 6+ Adsorption under the respective optimal adsorption conditions, using the same concentration of chromium solution and passing through the resin c...

Embodiment 2

[0031] Embodiment two processes the solution containing vanadium and chromium with the inventive method

[0032] The pH value is about 2.5 and contains hexavalent chromium 200mg.L -1 , Pentavalent vanadium 34mg.L -1 The acidic vanadium-precipitating wastewater is passed to the exchange column equipped with 150g Rohm and Haas IRA96RF macroporous anion exchange resin adjusted to pH 2.5 and the flow rate is controlled to be 80ml.min -1 , a total of 30L of waste water was adsorbed, and V in the residual liquid was adsorbed 5+ -1 , Cr 6+ -1 , up to the national discharge standard, desorb with 40ml40% sodium hydroxide, then clean the resin with 40ml desorption solution containing chromium and vanadium with low concentration, and finally clean the resin slowly with 60ml water. About 30ml obtained at the beginning of desorption is vanadium chromium standard water, about 70ml of intermediate desorption is concentrated desorption solution, and the last 40ml is desorption solution wit...

Embodiment 3

[0035] Embodiment three processes the solution containing vanadium and chromium with the inventive method

[0036] The pH value is around 2.5 and contains 1.44g.L of hexavalent chromium -1 , Pentavalent vanadium 0.12g.L -1 The acidic vanadium-precipitated wastewater is passed to the exchange column equipped with 150g Rohm and Haas IRA96RF macroporous anion exchange resin adjusted to pH 2.5 and the flow rate is controlled to be 10ml.min -1 , a total of 4.0L of wastewater was adsorbed, and V 5+ -1 , Cr 6+ -1 , up to the national discharge standard, use 50ml of 28% ammonia water for desorption, then use 40ml of desorption solution containing chromium and vanadium with low concentration to slowly clean the resin, and finally use 60ml of water to slowly clean the resin. During desorption, about 30ml of vanadium-chromium standard water is desorbed at the beginning, about 70ml of desorbed in the middle is concentrated desorption solution, and the last 40ml is desorption solution w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com