Moisture-permeable outer wall structure for reinforced concrete insulation building, composite panel used and wall protection kerb demarcation hardware

A technology of reinforced concrete and moisture permeability, which is applied in the direction of building components, building structures, buildings, etc., can solve the problems of small effect, complicated and difficult composite panels, and achieve excellent performance in preventing condensation and preventing overheating, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

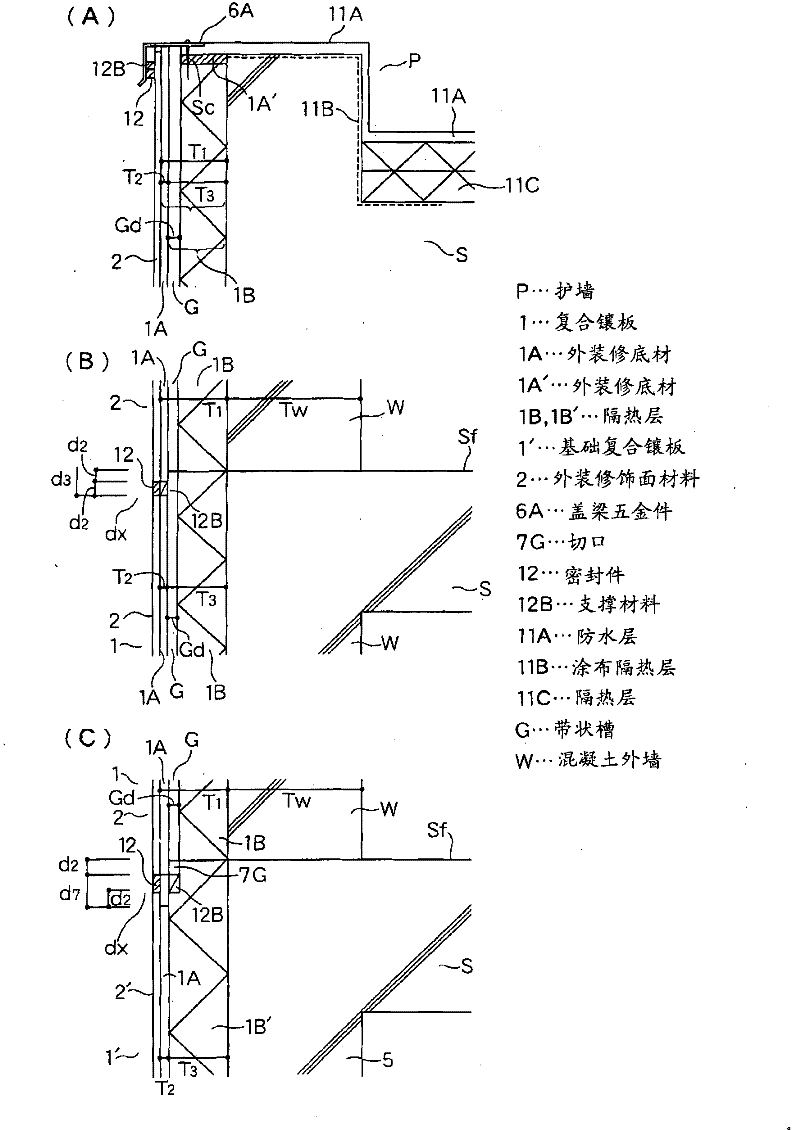

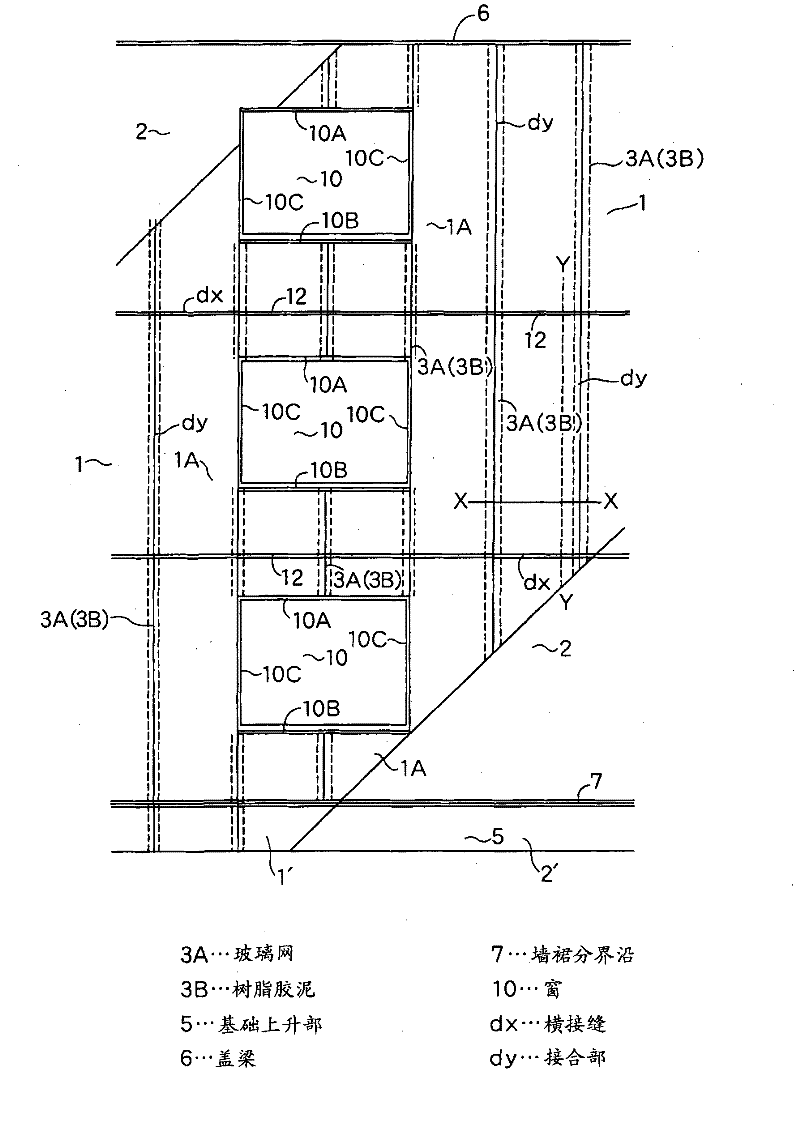

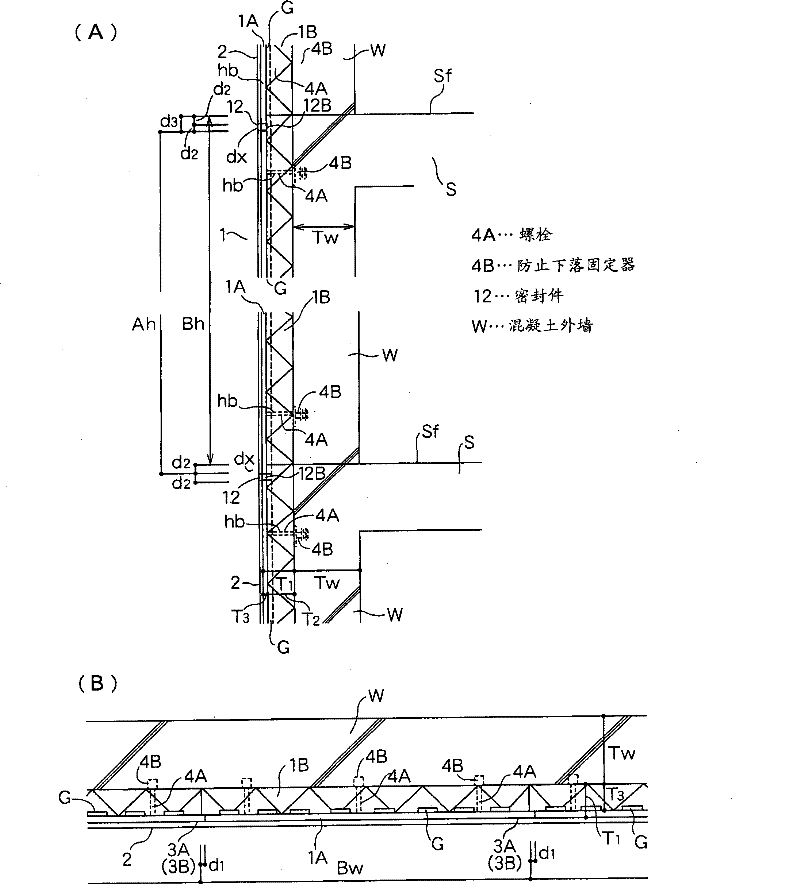

[0200] [Composite panel 1 ( Figure 5 , Image 6 )]

[0201] The composite panel 1 is typically used as an outer screed formwork for a concrete outer wall W, Figure 5 (A) is a perspective view seen from the cement board (exterior finishing substrate) 1A side, Figure 5 (B) is the front view from the cement board side, Image 6 (A) is a longitudinal sectional view, Image 6 (B) yes Image 6 (A) Enlarged view of part B.

[0202] Composite panel 1, such as Image 6 As shown in (A), it is a laminated board of thermal insulation layer 1B and cement board 1A. The thermal insulation layer 1B is extruded polystyrene foam (JISA9511) with a thickness T3 of 75mm. Image 6 As shown in (B), a magnesia cement board 1A-1 having magnesia and silica sand as main components and glass fiber non-woven fabric GC embedded on both sides can be used. 120kgf / cm 2 , moisture permeability resistance 14m 2 hmmHg / g formed thin rigid board, in the standard panel 1, the width of the insulation la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com