Retroreflection sheet

A technology of retroreflection and specular reflection, applied in optics, instruments, optical components, etc., can solve the problems of weather resistance and durability, and achieve the effect of excellent durability and excellent visibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

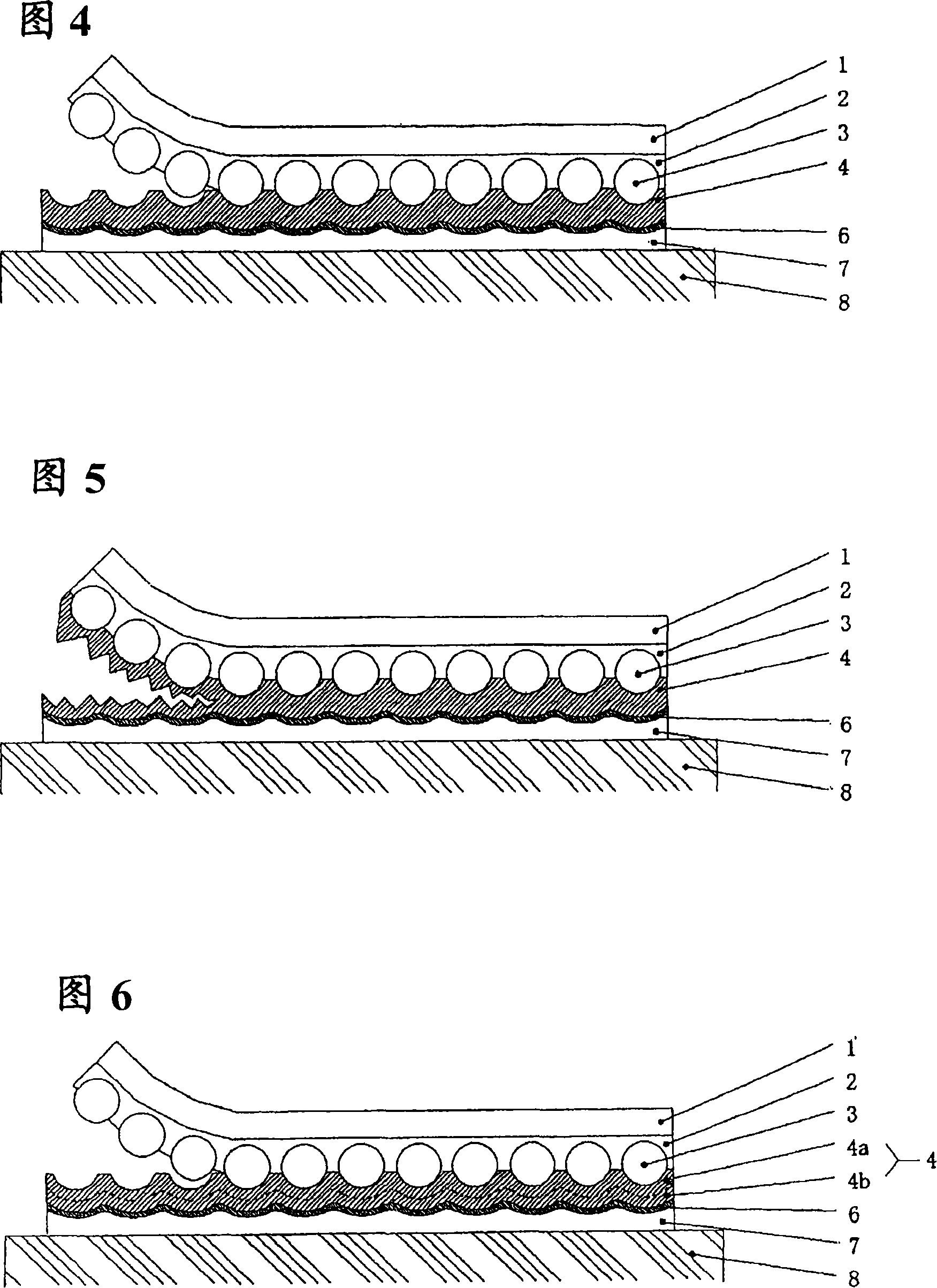

[0277] A transparent polyethylene terephthalate film (trade name, Teijin Tetron Film S-75) manufactured by Teijin Co., Ltd. with a thickness of 75 μm was used as a carrier film, and the mixed solution was coated on it, and then dried, and set to dry. A surface layer (1) with a thickness of 18 μm (see FIG. 4 ). Wherein said mixed solution is that the number of substitutions of the formaldehyde prepared by 100 parts by weight of Japan Ka-Baido Industry Co., Ltd.'s acrylic resin solution (trade name, Nitsuset RS-1200) and 14 parts by weight of the company's three and chemical preparation is 6 21.1 parts by weight of methyl isobutyl ketone and 5.3 parts by weight of toluene were added as a solvent to a methylated melamine resin solution (trade name, Nikarak MS-11), and stirred and mixed. Wherein the acrylic resin solution is a copolymer with a weight average molecular weight of about 250,000 of ethyl acrylate / methyl methacrylate / 2-hydroxyethyl methacrylate (weight ratio 65 / 21 / 14) ...

Embodiment 2

[0291] A transparent polyethylene terephthalate film (trade name, Teijin Tetron Film S-75) manufactured by Teijin Co., Ltd. with a thickness of 75 μm was used as a carrier film, and the mixed solution was coated on it, and then dried, and set to dry. A surface layer (1) with a thickness of 18 μm (see FIG. 6 ). Wherein said mixed solution is the methylated melamine resin solution (trade name, Nitsuset RS-1200) prepared by 100 parts by weight of Japan Ka-Baido Industry Co., Ltd. and the methylated melamine resin solution prepared by Sanwa Chemical Co., Ltd. of 14 parts by weight (trade name, Nicaratsu MS-11) was added as a solvent, 21.1 parts by weight of methyl isobutyl ketone, and 5.3 parts by weight of toluene, and stirred and mixed.

[0292] Then, the mixed solution was applied on the above-mentioned surface layer and dried to form a holding layer (2) having a thickness of 27 μm after drying. Wherein said mixed solution is an acrylic resin solution (trade name, Nitsuset RS-...

Embodiment 3

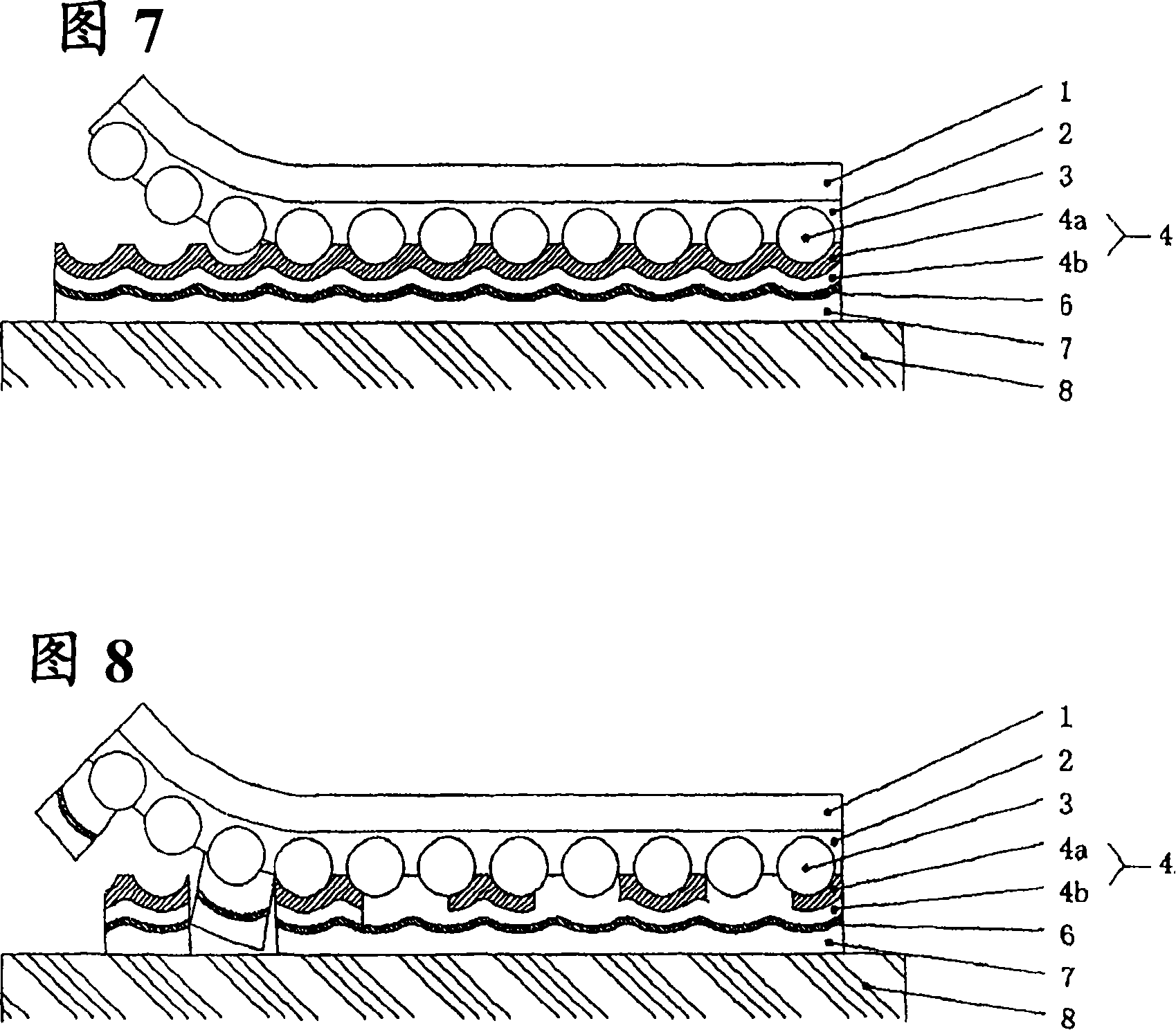

[0304] A transparent polyethylene terephthalate film (trade name, Teijin Tetron Film S-75) manufactured by Teijin Co., Ltd. with a thickness of 75 μm was used as the process film, and the mixed solution was coated on it with a coater, followed by drying , and provided a dried surface layer (1) having a thickness of 18 μm (see FIG. 7 ). Wherein said mixed solution is the methylated melamine resin solution (trade name, Nitsuset RS-1200) prepared by 100 parts by weight of Japan Ka-Baido Industry Co., Ltd. and the methylated melamine resin solution prepared by Sanwa Chemical Co., Ltd. of 14 parts by weight (trade name, Nicaratsu MS-11) was added as a solvent, 21.1 parts by weight of methyl isobutyl ketone, and 5.3 parts by weight of toluene, and stirred and mixed.

[0305] Further, the mixed liquid was applied on the above-mentioned surface layer (1), and then dried to form a holding layer (2) having a thickness of 27 μm after drying. Wherein said mixed solution is an acrylic res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com