Pinenut kernel peeling and selecting device

A sorting device and pine nut technology, applied in the field of food processing, can solve the problems of low efficiency, unhygienic, high labor intensity, etc., and achieve the effects of long service life, reasonable structure, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

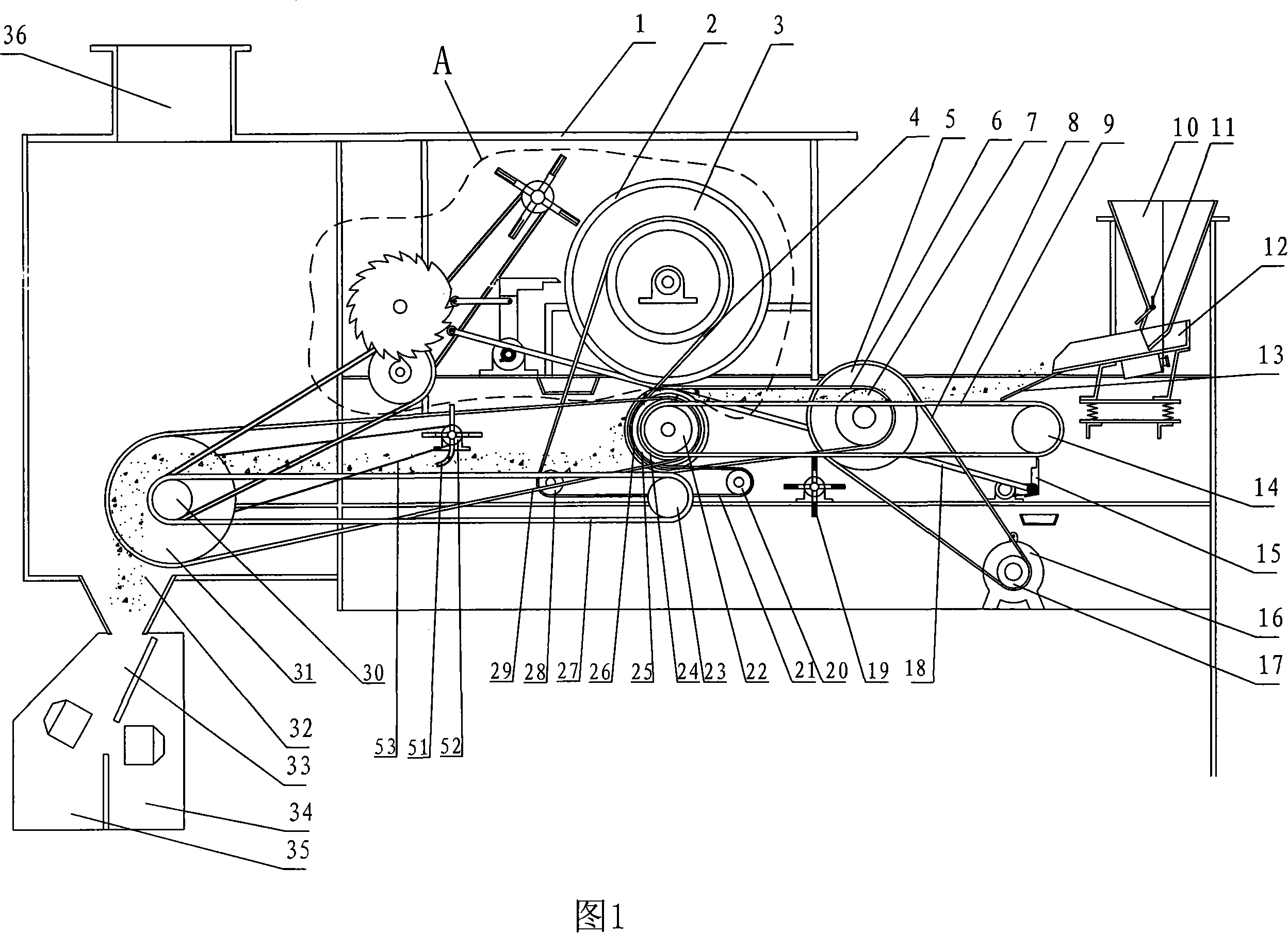

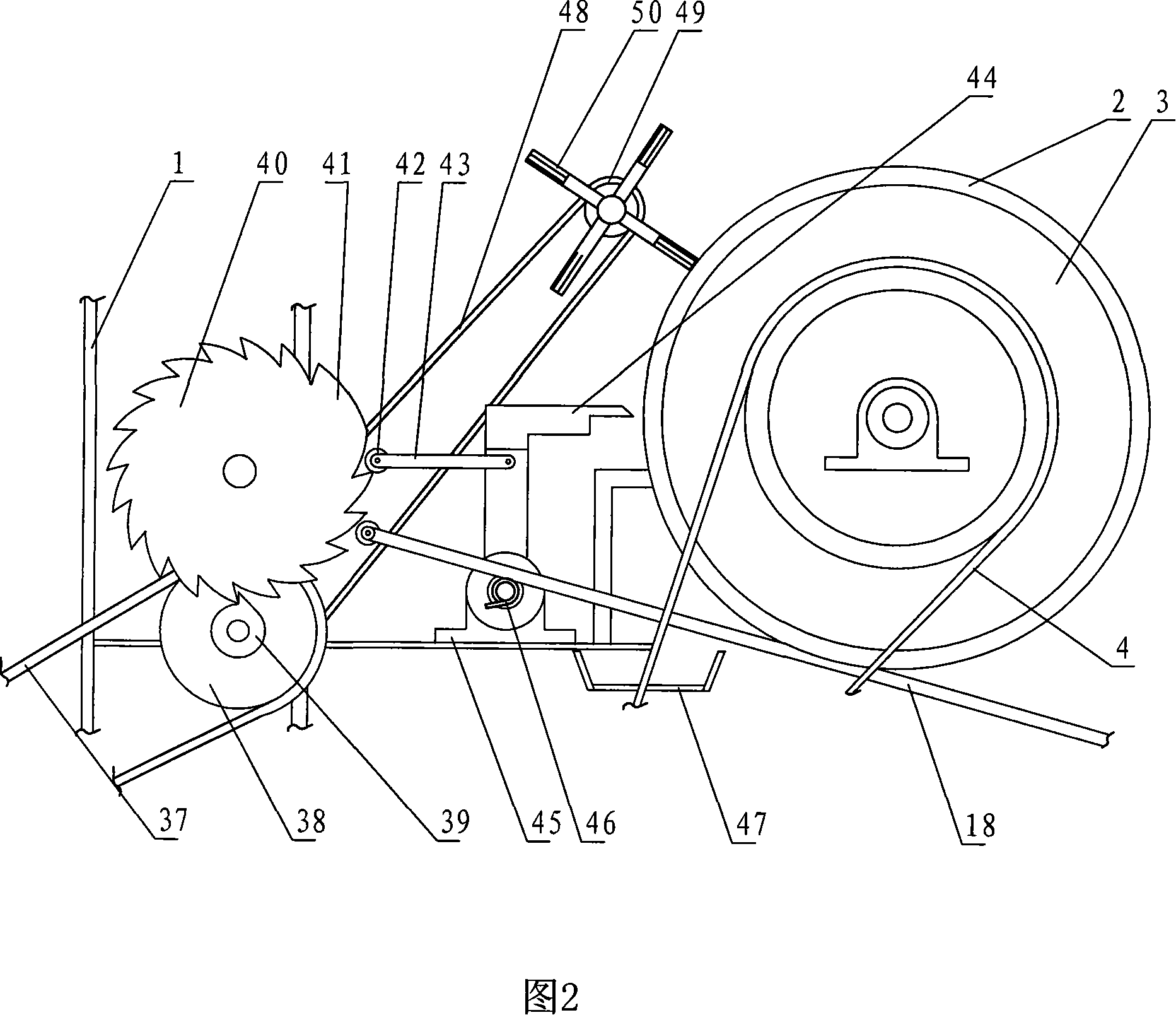

[0014] Shown in Figures 1 to 2, 1 in the figure is a frame, 16 is a motor, a pine nut hopper 10 is fixedly arranged on the upper part of the right side of the frame 1, and an electromagnetic The vibrating distributor 12 is provided with a flow control plate 11 on the position of the discharge port of the electromagnetic vibration distributor 12, and an elastic conveyor belt 9 is arranged on the lower part of the position of the discharge port of the electromagnetic vibration distributor 12. A feeding bridge plate 13 with a slope is also arranged between the elastic conveyor belt 9; the rotation of the elastic conveyor belt 9 is the V-belt 8 controlled by the motor output shaft 17, the driven wheel 5, the rotating shaft 7, the V-belt 6 and the The rotating shaft 26 drives the transmission wheel 24 to rotate, and the output shaft 22 that rotates synchronously with the transmission wheel 24 drives the elastic conveyor belt 9 to rotate along the driven wheels 14. The circumferentia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com