Roller surface laser texturing and micro-alloying composite processing method

A technology of laser texturing and roll surface, applied in metal processing equipment, laser welding equipment, manufacturing tools, etc., can solve the problem of shallow fusion pit depth, limited improvement in strength and friction and wear performance, and insufficient texturing point bosses and other problems, to achieve the effect of strengthening hardness and friction and wear performance, height improvement, and clear edges of textured points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

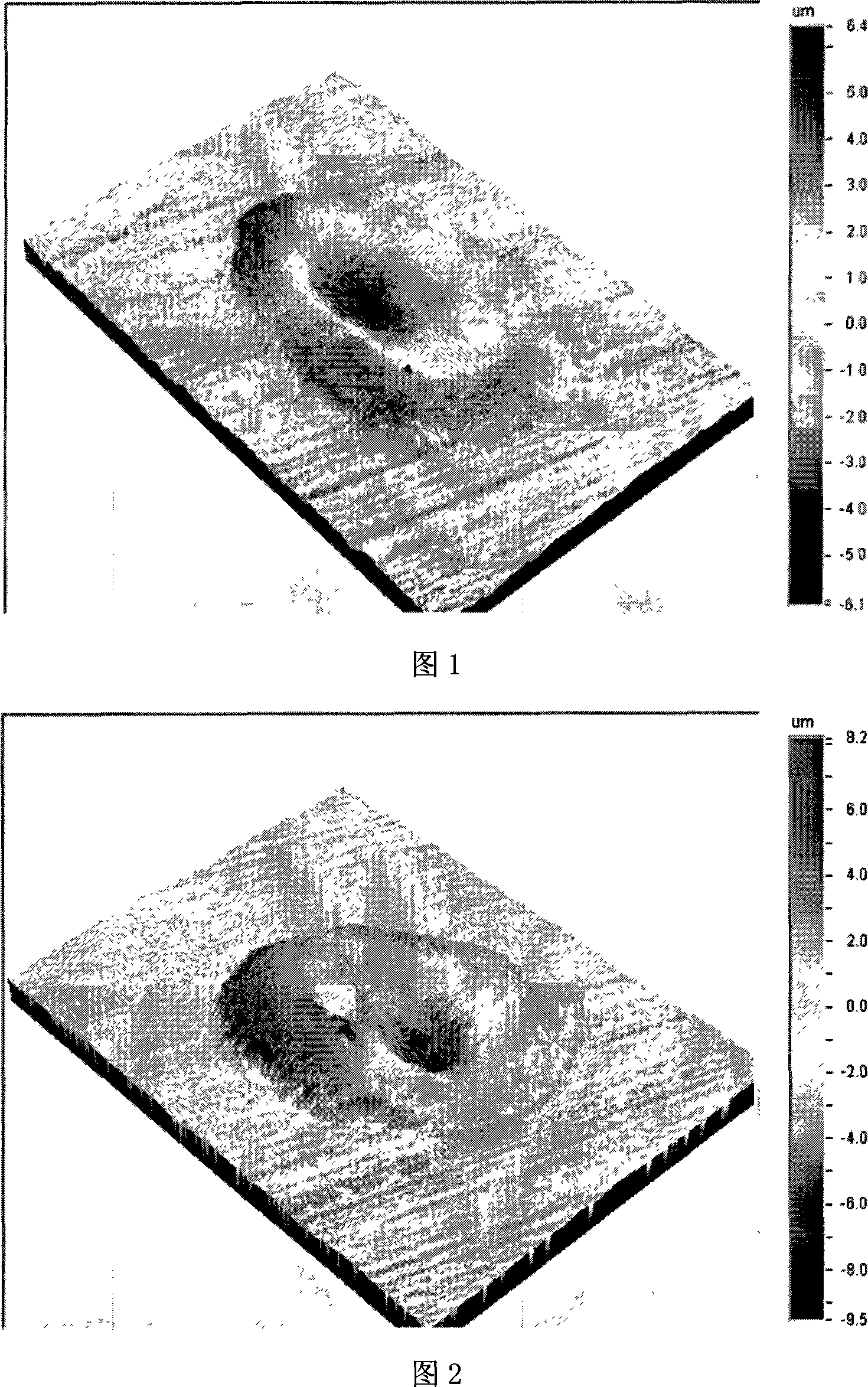

[0017] Example 1: Firstly, a mixture of alloy micropowder and latex needs to be prepared. The alloy micropowder is WC+TiC+Co mixed powder with a particle size of 2-4 μm. Use 2123 phenolic resin and alcohol to make latex with a concentration of 13%, then mix the prepared latex and alloy powder evenly according to the volume ratio of about 6:1, and spray it on the surface of the GCr15 roll cleaned by ethanol through a spray gun, so that The alloy powder is closely and evenly combined with the roll, and at the same time increases the absorption of laser light energy on the roll surface. Due to the volatility of alcohol, the coating dries quickly. Thin film coating thickness ranges from 0-0.5mm. Alloy powder can be sprayed before laser texturing or laser texturing and spraying at the same time. After the surface film of the roll is prepared, it is textured with pulsed laser beams, and after the texturing is completed, the untextured part is cleaned with alcohol or acetone. Duri...

Embodiment 2

[0019] Embodiment 2: WC-Cr powder (30% by weight of Cr) is selected as the alloy powder, and the particle size is less than 10 μm. Use 2123 phenolic resin and acetone to make latex with a concentration of 13%, then mix the prepared latex and alloy powder according to the volume ratio of about 2:1, and the thickness of the film coating varies from 0-0.5mm as required. The method of spraying treatment is the same as that of Embodiment 1. After texturing, compared with the direct texturing method, the depth and height of the texturing pits are increased. The hardness of the coating reaches about HV900, and the wear resistance of the surface increases by about 10% under dry friction.

Embodiment 3

[0020] Embodiment 3: WC-Co powder (Co weight ratio: 10%) is selected as the alloy powder, and the particle size is less than 10 μm. The polyvinyl butyral alcohol solution and the alloy powder are mixed evenly according to the volume ratio of about 3:1, and the film coating thickness is 0-0.5mm. The method of spraying treatment is the same as that of Embodiment 1. After texturing, the depth and height of the texturing pits are increased compared with the direct texturing method. The hardness of the coating reaches about HV1000, and the wear resistance of the surface increases by about 15% under dry friction. Due to the effect of alloying, the hardness and friction and wear properties of each part of the textured point are also improved accordingly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com