Manganese dioxide reference electrode

A manganese dioxide ginseng and electrode technology, applied in the field of cathodic protection, can solve the problems of poor drying resistance, unstable temperature coefficient, poor drying resistance of electrodes, etc., and achieve the effect of firm structure and long-term performance stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

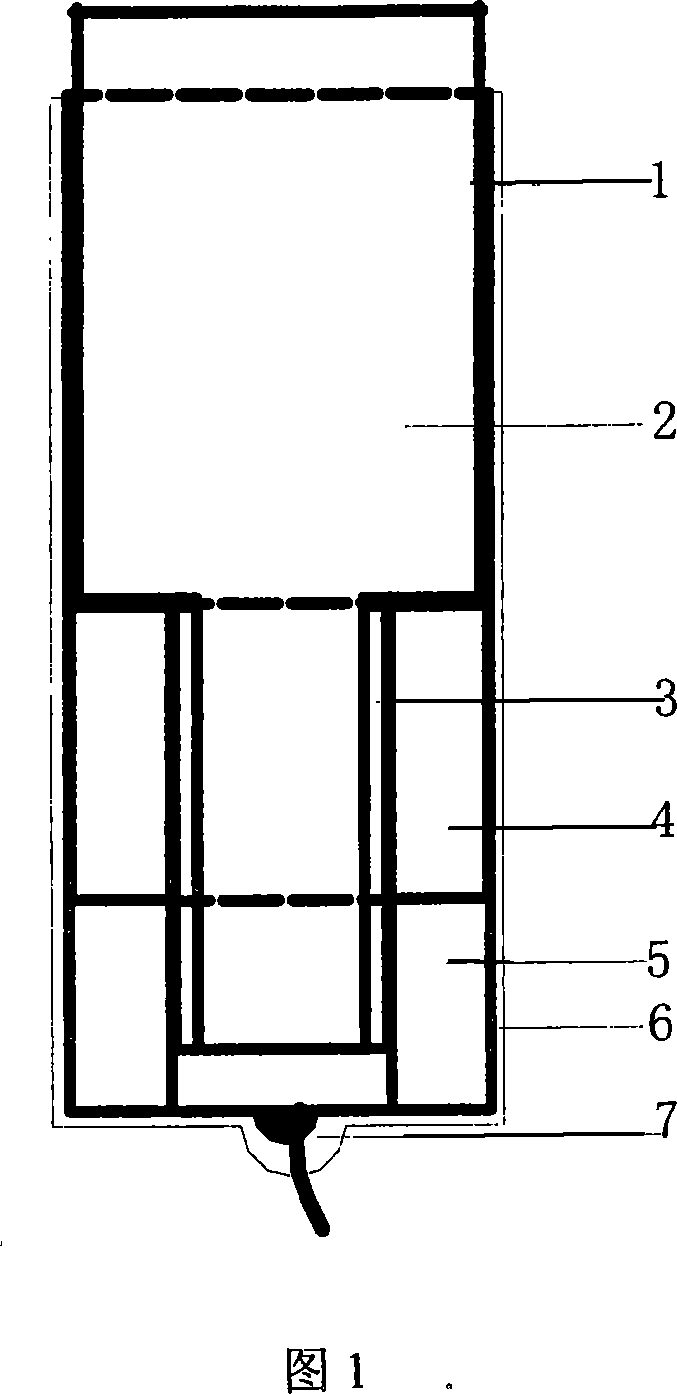

Image

Examples

Embodiment 1

[0016] Select β-titanium manganese dioxide powder with a particle size between 300 and 400 meshes. After surface water removal treatment, the treatment temperature is 120°C and the treatment time is 30 minutes; take 70% of the treated manganese dioxide powder according to weight percentage; Stone 20%; 1mol / L KOH solution 1.5%; 7.5% acetylene black powder and 1% polytetrafluoroethylene emulsion, fully mixed by mechanical means, and ground for 60 minutes, using a hydraulic machine, the above mixed powder in the tool Compressed in a steel mold and assembled according to the manufacturing process to obtain a manganese dioxide reference electrode, the potential of which is stable at 68±5mV.

Embodiment 2

[0018] Choose γ-titanium manganese dioxide powder with a particle size between 300 and 400 meshes, after surface water removal treatment, the treatment temperature is 120°C, and the treatment time is 30 minutes; take 80% of the treated manganese dioxide powder according to weight percentage; Stone 15%; 9mol / L KOH solution 1.5%; 2.5% acetylene black powder and 1% polytetrafluoroethylene emulsion, fully mixed by mechanical means, and ground for 60 minutes, using a hydraulic machine, the above mixed powder in the tool Compressed in a steel mold and assembled according to the manufacturing process to obtain a manganese dioxide reference electrode, the potential of which is stable at 68±5mV.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com