Low temperature continuous casting heat patching method and its automatic heat patching device

A continuous casting and automatic technology, applied in the field of heat supplementation of low temperature continuous casting, can solve the problems of insignificant improvement of product quality, high comprehensive cost of supplementary heat, large consumption of argon gas, etc., and achieves reduction of metal loss and metal yield. Enhancement, reduction of metal oxides and non-metal oxides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

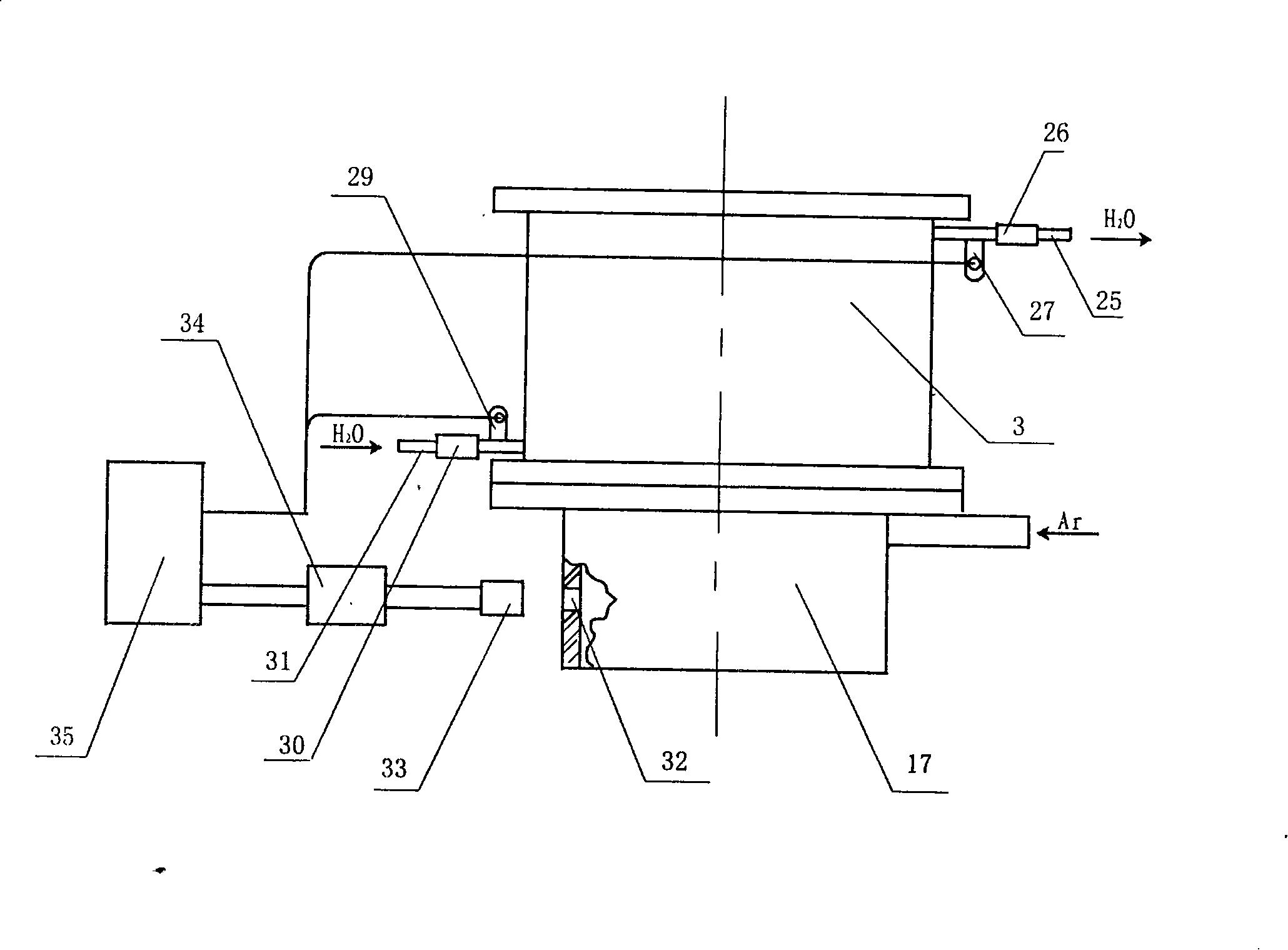

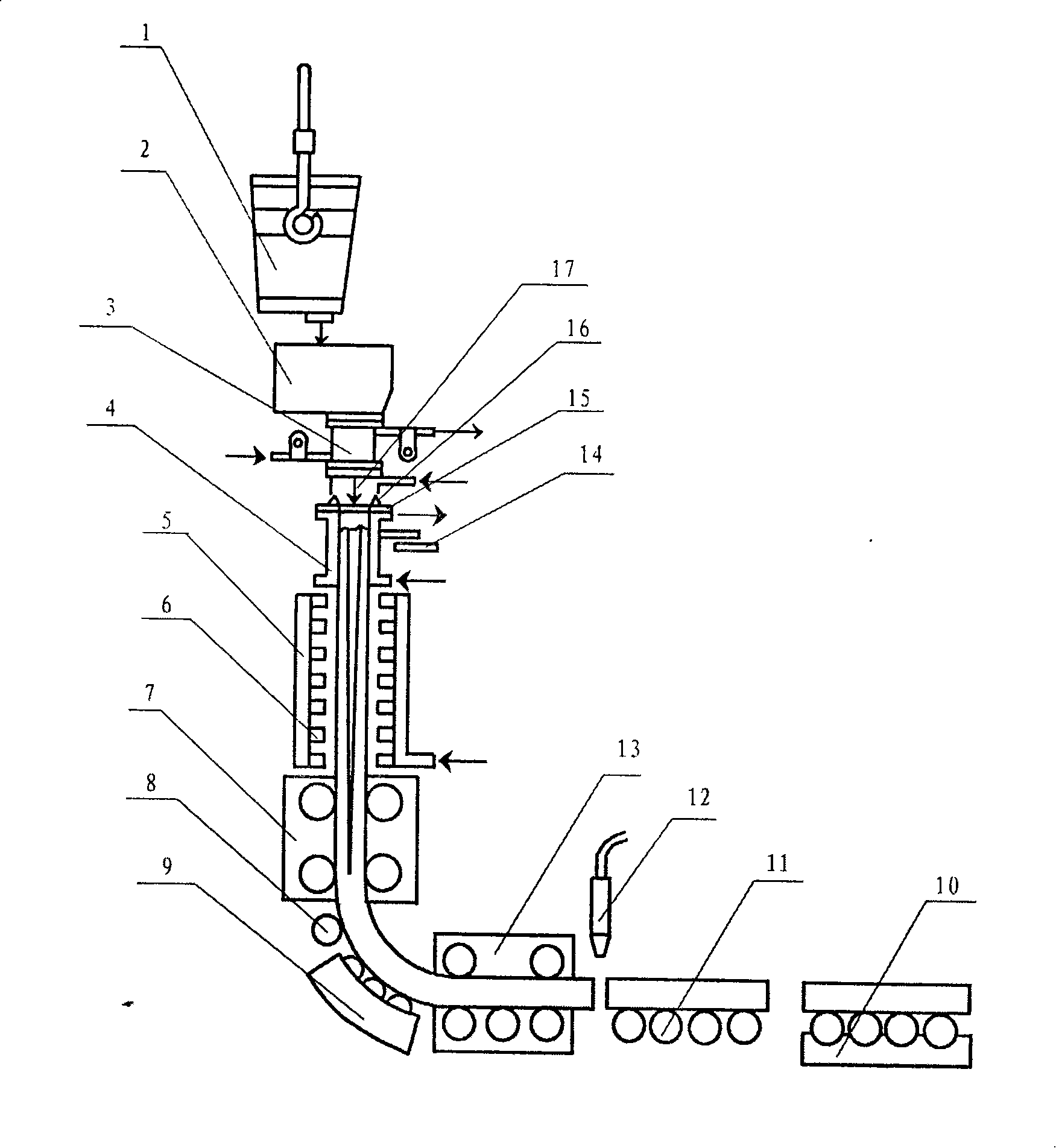

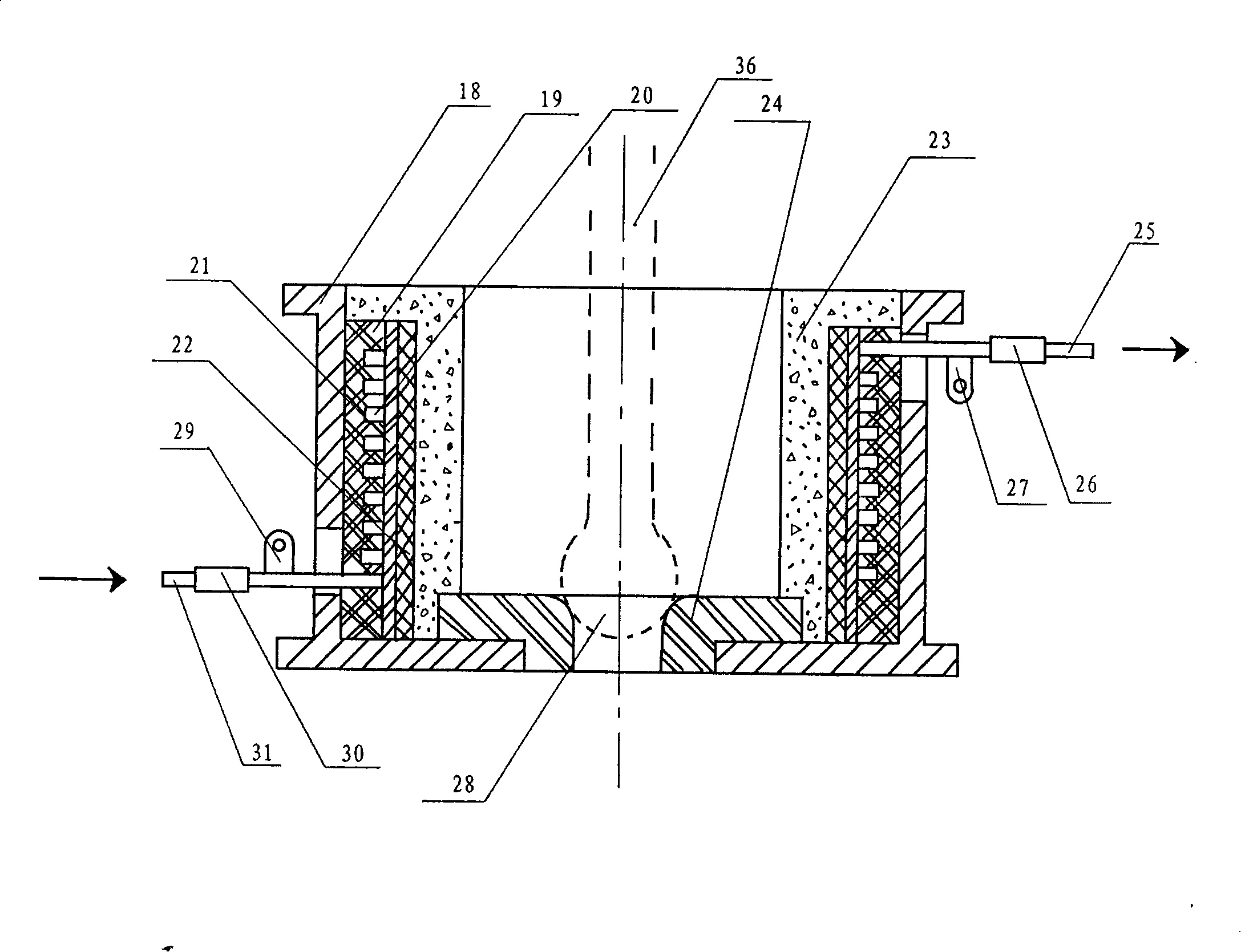

[0015] The present invention relates to a heat replenishing method for low-temperature continuous casting. A molten steel heat replenishment zone is provided between the tundish 2 and the crystallizer 4 of the continuous casting device, and an automatic heat replenishment device is provided in the heat replenishment region to automatically replenish heat. The device uses a non-contact temperature sensor 33 to measure the temperature of the molten steel after heating, and uses a coreless intermediate frequency induction heating method to dynamically and continuously replenish the molten steel in the heat replenisher 3 flowing from the tundish 2 into the heat replenishment device. The molten steel at the set temperature flows into the inner cavity of the crystallizer 4 through the inert gas protective cover 17. When the molten steel in the supplementary heater 3 is supplemented with heat, part of the heat energy of the molten steel in the supplementary heater 3 can be passed throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com