Partial heating and insulation device for crude oil cold transportation pipeline passing through the frozen layer vertically

A technology for conveying pipelines, heating and heat preservation, applied to pipeline systems, gas/liquid distribution and storage, mechanical equipment, etc., to achieve the effects of time-saving maintenance, smooth oil transportation, and high heat preservation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

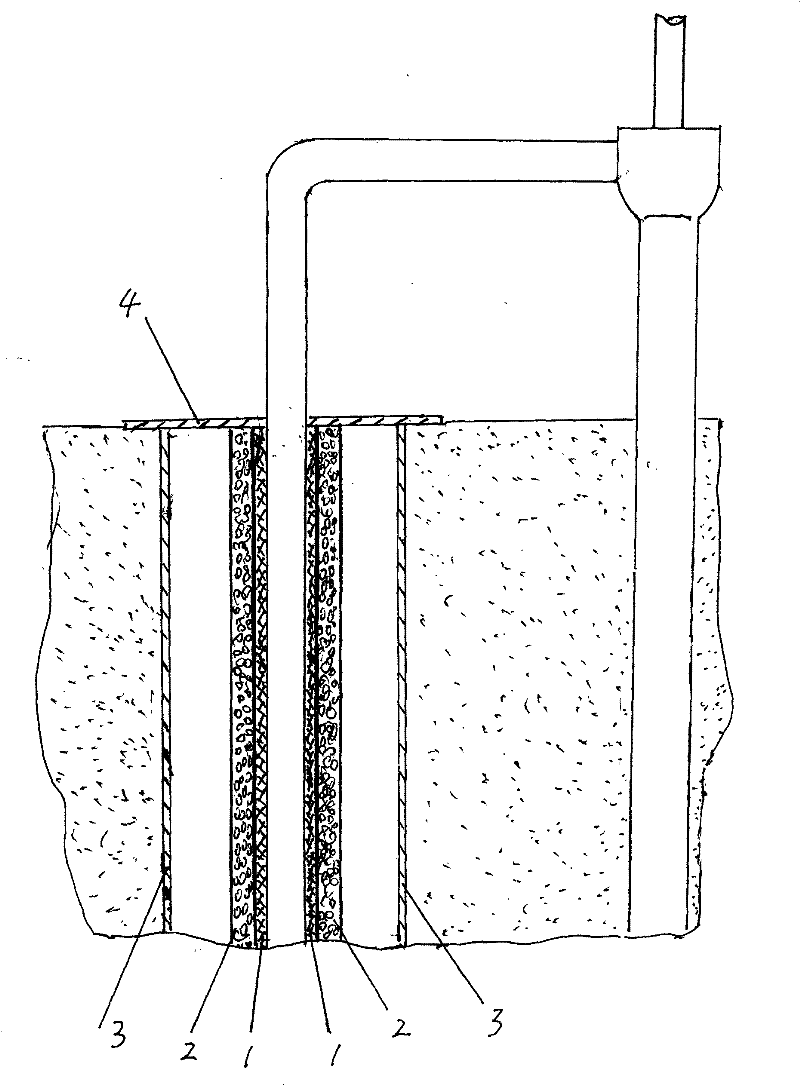

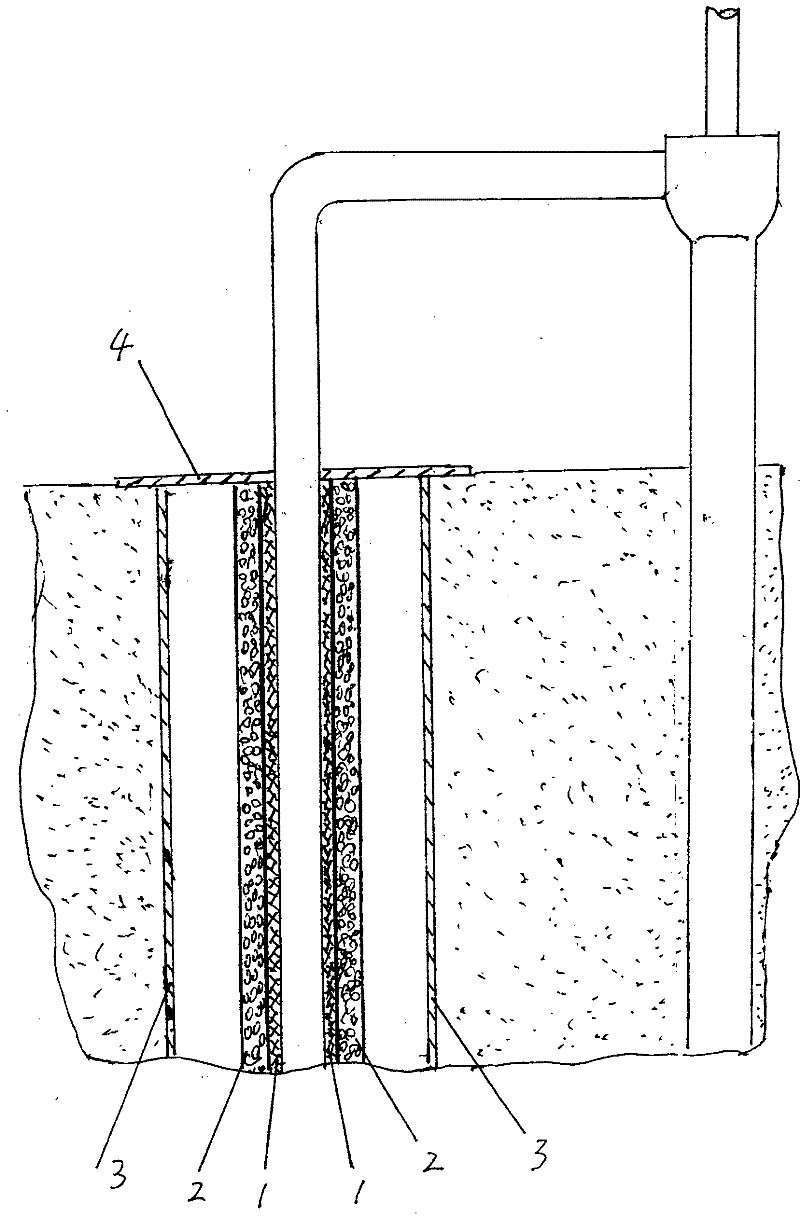

[0011] Embodiments of the present invention are given below in conjunction with the accompanying drawings.

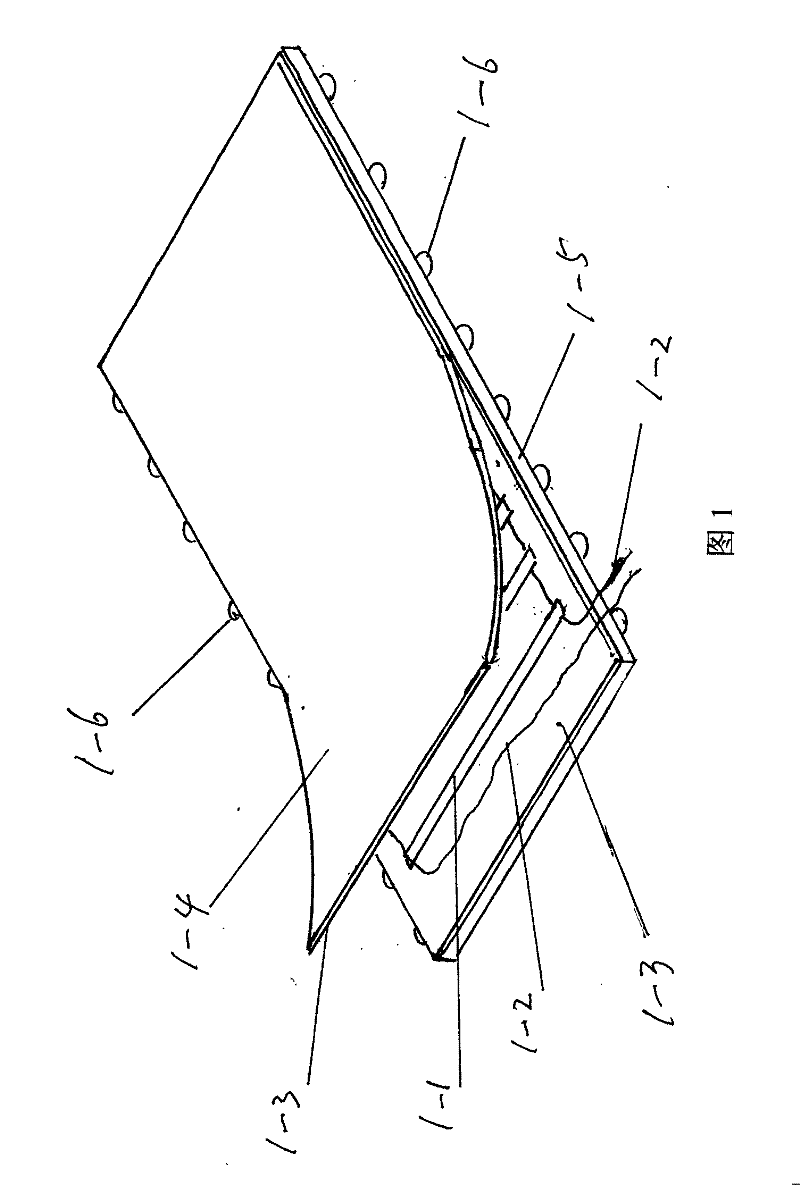

[0012] 1. Making figure 1 , figure 2 The electrothermal layer 1 shown.

[0013] Get 10 parts by weight of conductive carbon black, 10 parts by weight of nano-graphite powder, 15 parts by weight of latex rubber, 2 parts by weight of paraffin wax, and 2 parts by weight of liquid coumarone, and mix uniformly at 50kg / cm 2 Pressure pressed into thin slices with a thickness of 1-2mm, cut into electric heating strips, 1-1. The length of the electric heating strip is determined according to the circumference of the oil pipeline, and the electric heating strip is distributed according to the length of the oil pipeline to be kept warm and the required power. After connecting the electrodes 1-2, press and seal with polyurethane film 1-3, and the surface of polyurethane is coated with aluminum film 1-4 , forming a heating sheet, attaching thermal insulation material 1-5 on one ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com