Two-stage rotating wheel dehumidification air conditioner device capable of using low-grade heat source

A low-grade heat source and wheel dehumidification technology, applied in household heating, air-conditioning systems, applications, etc., can solve problems such as complex structure, inability to remove moisture, difficulties, etc., to meet comfort requirements, significant emission reduction effect, easy The effect of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

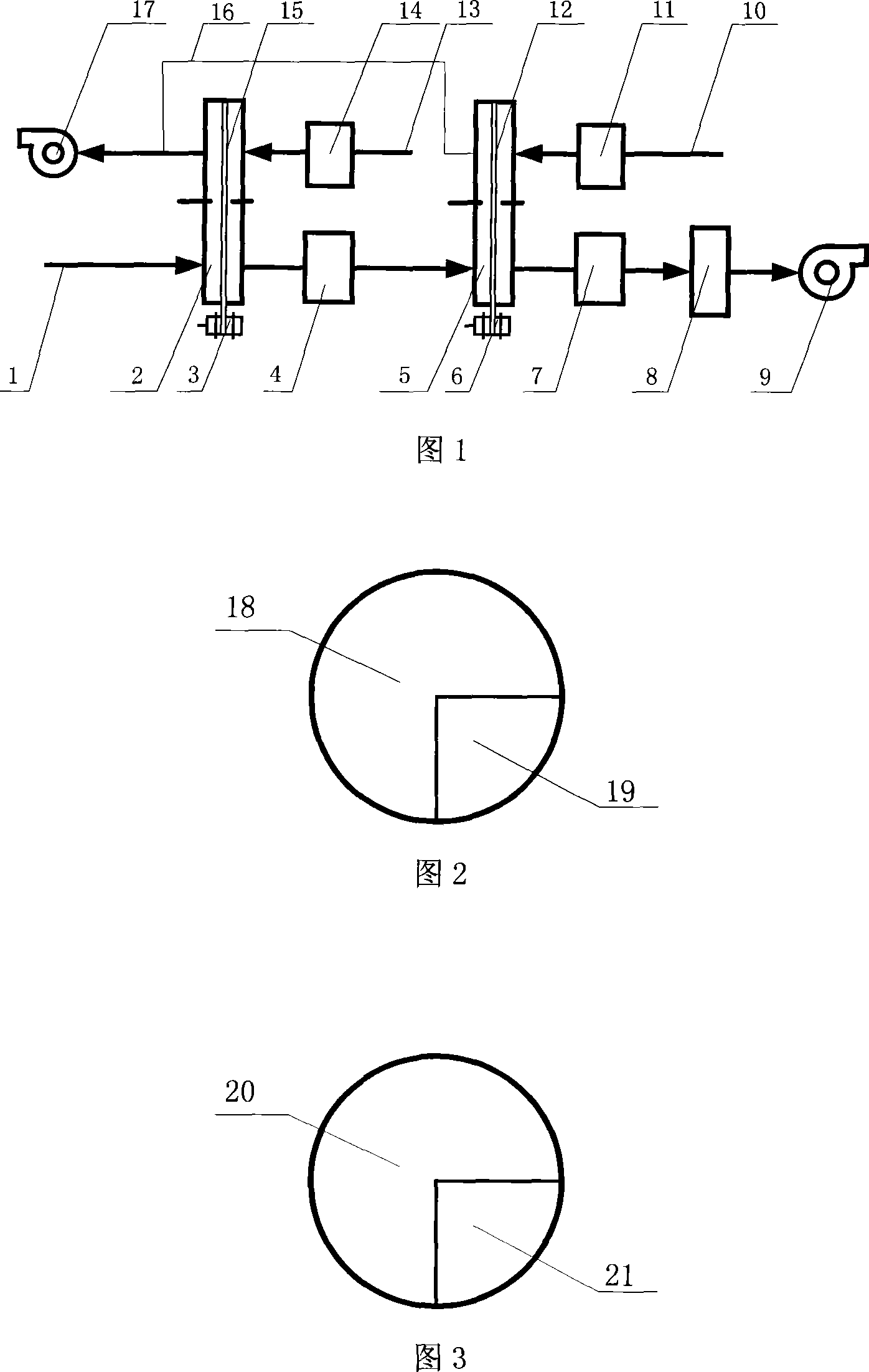

Embodiment 1

[0032] The structure of this embodiment is shown in Figure 1, and this embodiment includes: a processing air inlet duct 1, a first-stage dehumidification runner 2, a first-stage dehumidification runner drive motor 3, a first-stage treatment heat exchanger 4, and a first-stage dehumidification runner drive motor 3. Second-stage dehumidification rotor 5, second-stage dehumidification rotor drive motor 6, second-stage treatment heat exchanger 7, evaporative cooler 8, treatment fan 9, second-stage regenerative air inlet duct 10, second-stage regenerative heating Device 11, second-stage dehumidification runner drive belt 12, first-stage regeneration air inlet duct 13, first-stage regeneration heater 14, first-stage dehumidification runner drive belt 15, second-stage regeneration air outlet duct 16 , regeneration fan 17.

[0033] As shown in Figure 2, the first stage dehumidification rotor 2 treatment area 18 and the regeneration area 19 account for 3 / 4 and 1 / 4 of the area of the ...

Embodiment 2

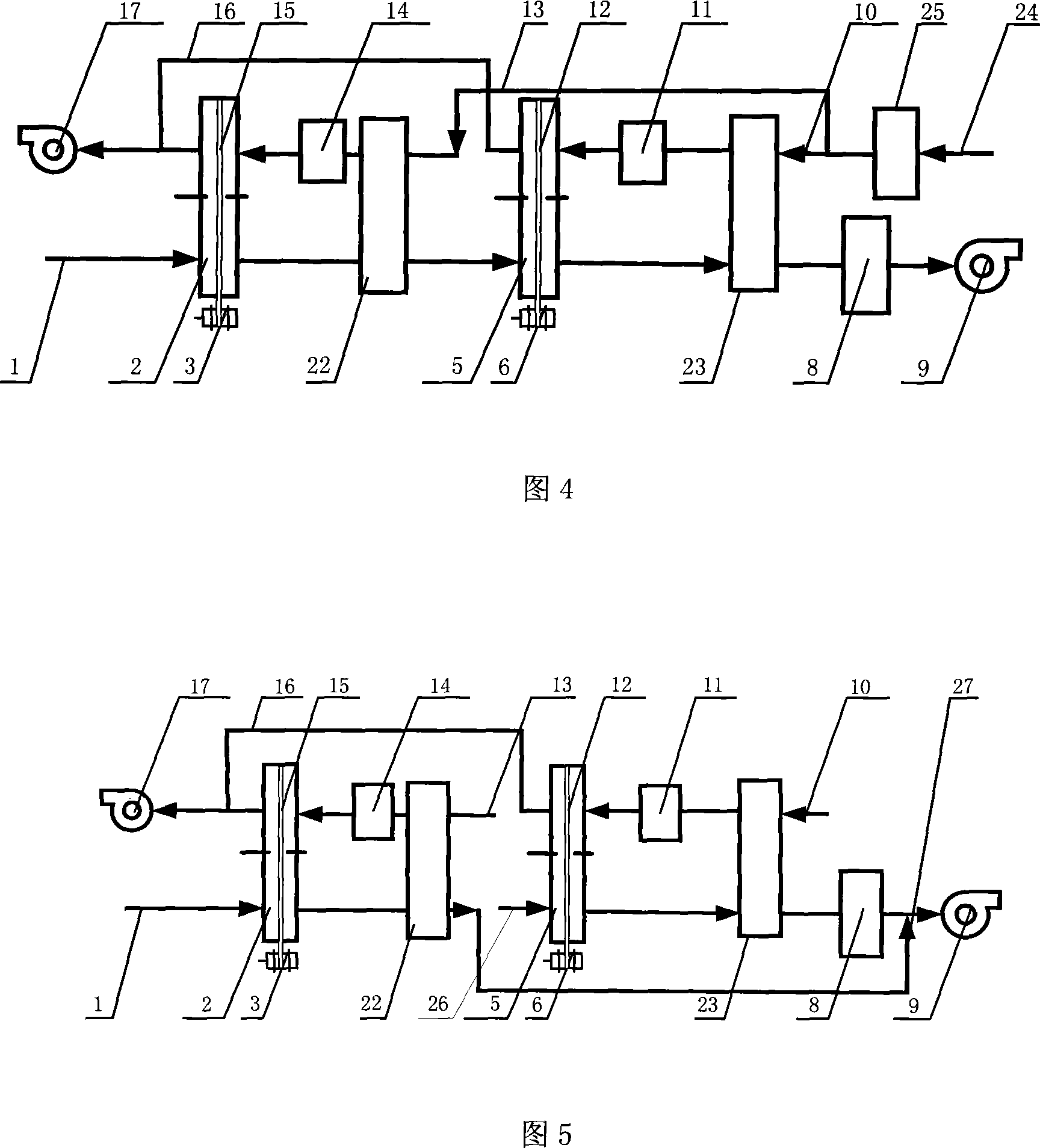

[0044] The structure of this embodiment is shown in Figure 4. The two-stage rotor dehumidification air conditioner includes: a processing air inlet duct 1, a first-stage dehumidification runner 2, a first-stage dehumidification runner drive motor 3, and a first-stage processing circuit. Heater 22, second-stage dehumidification runner 5, second-stage dehumidification runner drive motor 6, second-stage treatment regenerator 23, evaporative cooler 8, treatment fan 9, second-stage regeneration air inlet duct 10, Second-stage regenerative heater 11, second-stage dehumidification runner drive belt 12, first-stage regeneration air inlet duct 13, first-stage regeneration heater 14, first-stage dehumidification runner drive belt 15, second-stage regeneration Air outlet duct 16, regeneration fan 17, regeneration air inlet main pipe 24, regeneration side evaporative cooler 25. Figure 2 and Figure 3 are schematic diagrams of the first-stage dehumidification rotor 2 and the second-stage de...

Embodiment 3

[0054] The structural form of this embodiment is shown in FIG. 5 . Compared with Example 2, the structure of this embodiment has no evaporative cooler on the regeneration side and is only used for heating in winter.

[0055] Compared with Embodiment 2, the difference in its connection method is:

[0056] The treatment air passes through the treatment side outlet of the first-stage treatment regenerator 22 and is connected with the treatment blower 9 through the air duct 27 . The second-stage treatment air inlet pipe 26 is connected to the air inlet side of the treatment area of the second-stage dehumidification rotor 5, and the air outlet side of the treatment area of the second-stage dehumidification rotor 5 is treated with the second-stage treatment regenerator 23 through the air duct. The side inlets are connected, and the second-stage treatment regenerator 23 is connected to the evaporative cooler 8 through an air pipe. The evaporative cooler 8 is connected with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com