Road basal pelletized material mixture resilient modulus indoor test method and device

A technology of rebound modulus and road base, applied in the direction of measuring devices, analysis materials, material inspection products, etc., can solve the problems of difficult measurement results, road surface design, applicability limitations, modulus test value variation, etc., and achieve reliable test results Confidence, strong applicability, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

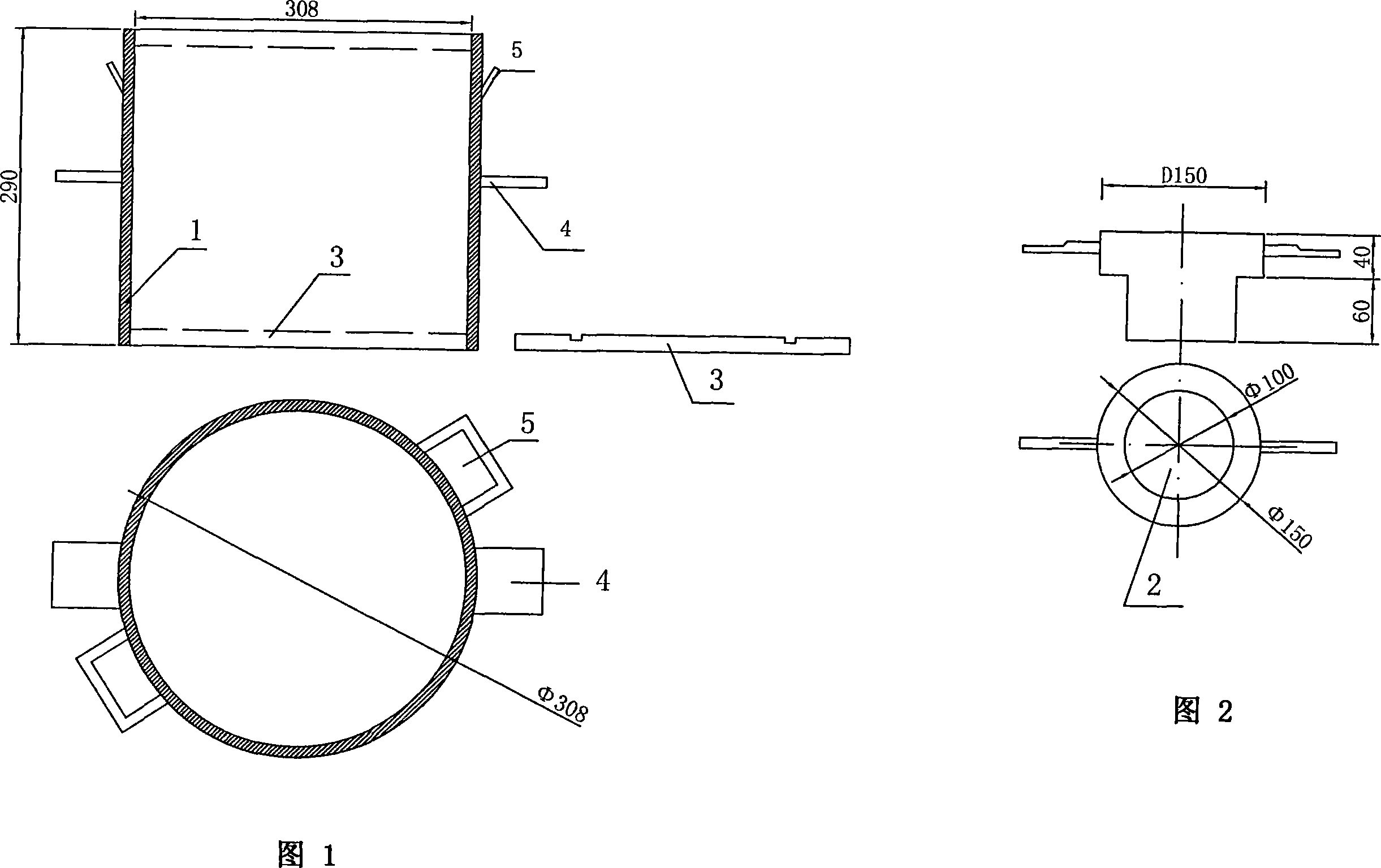

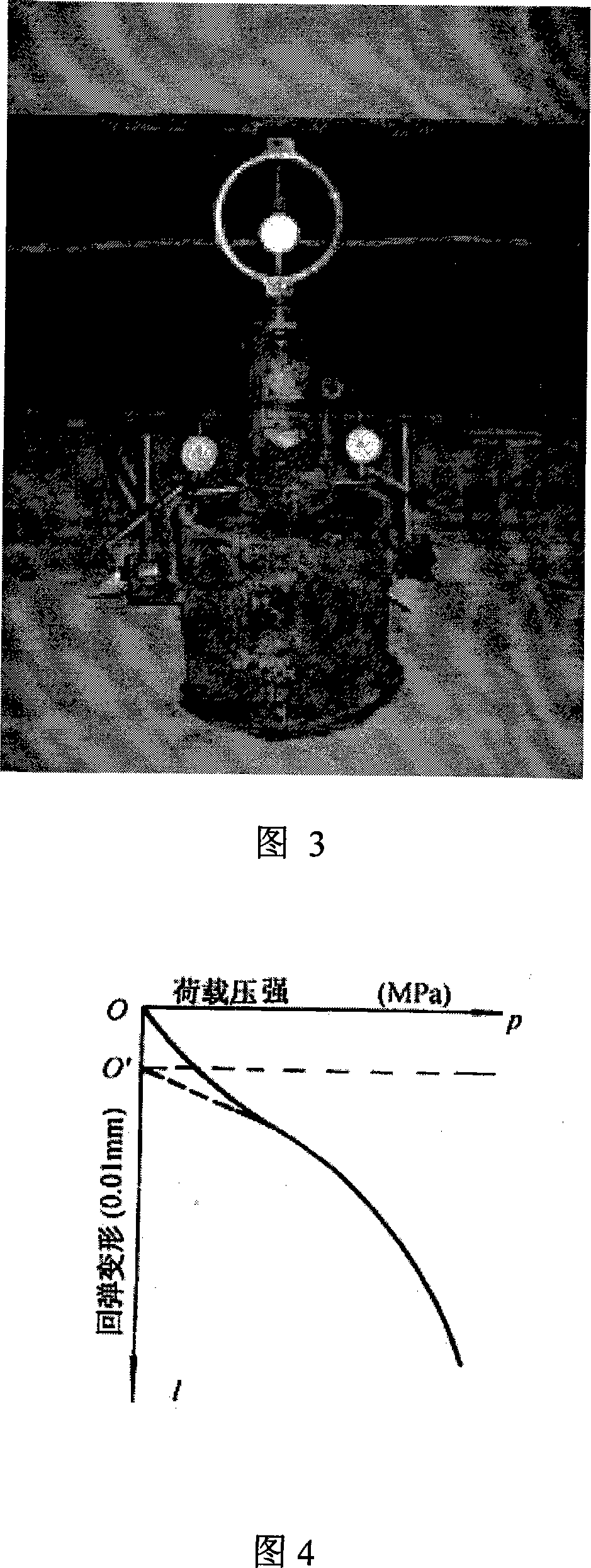

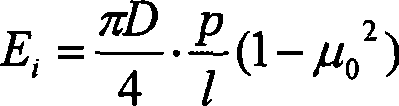

[0059] The indoor test method for the resilience modulus of the road base granular mixture includes the following steps: 1), adding the sample to the resilience modulus test tube; 2), static pressure molding of the sample; 3), placing the small load-bearing plate On the surface of the sample; 4), load, unload, and perform the modulus of resilience test; 5), read the amount of deformation; 6), take the value of the modulus of resilience; 7), process the test data to obtain the modulus of resilience value .

[0060] "Road Geotechnical Test Regulations" The diameter and height of the test cylinder for the resilience modulus test are D×H=152mm×170mm, and the diameter and height of the cushion block in the cylinder are D×H=151mm×50mm. The sample size is D×H=152mm×120mm. When gravel is used as the base layer, the maximum particle size reaches 37.5mm. If the particle size of the sample is too large or the size of the test tube is too small, it will inevitably bring a greater binding forc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com