Strong coupling multiple core optical fiber

A multi-core optical fiber and strong coupling technology, which is applied in the direction of multi-layer core/clad optical fiber, clad optical fiber, optical waveguide light guide, etc., can solve the problem that multi-core optical fiber is not easy to achieve strong coupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

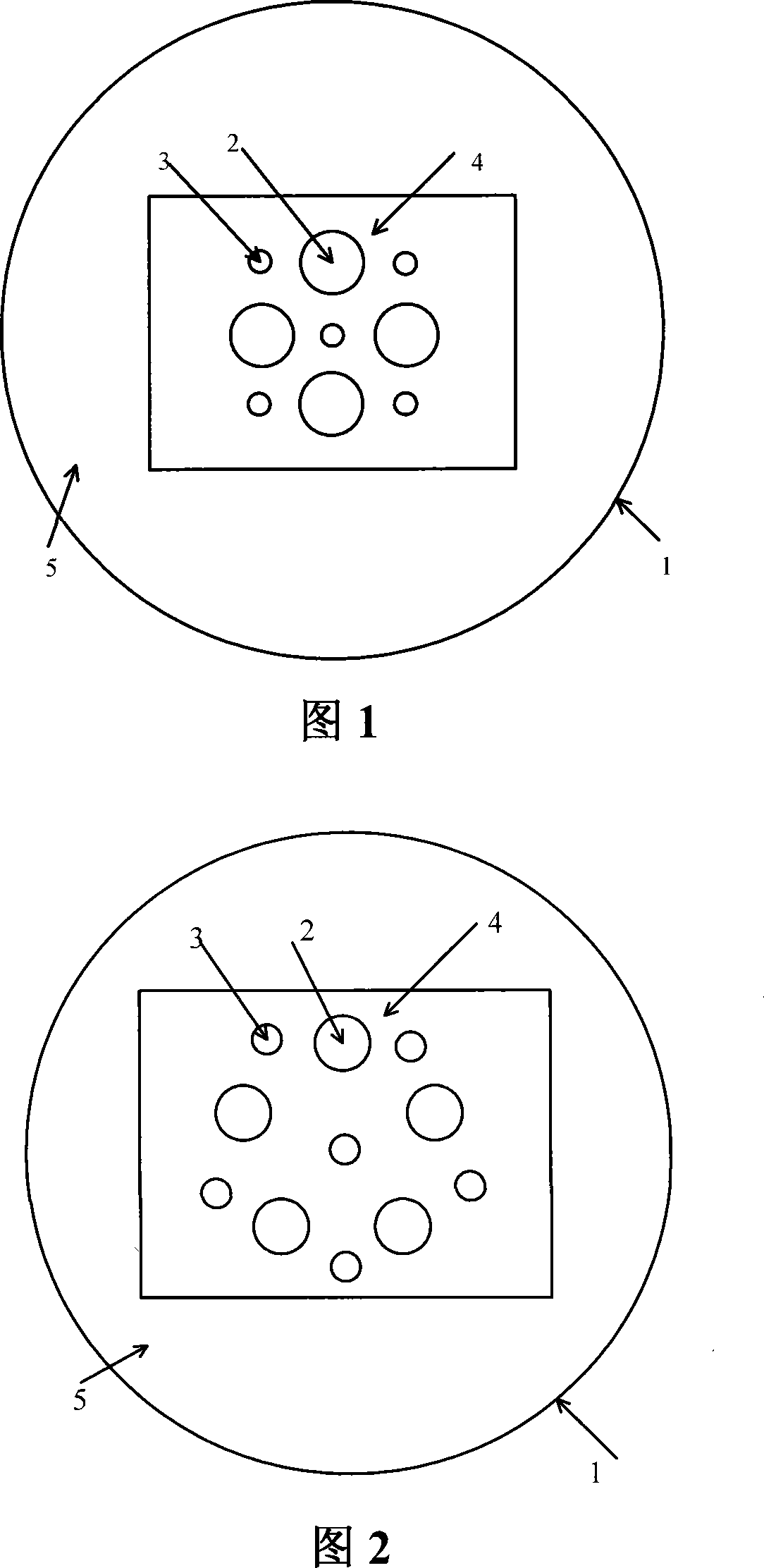

[0024] Fig. 1 is the cross-section schematic diagram of the fiber of embodiment 1 of the invention strong coupling multi-core fiber, as can be seen from the figure, this is that the large-diameter cores 2 in the inner cladding region 4 are arranged in a square, and the sub-wavelength diameter cores 3 are located in four Strongly coupled multi-core fiber between the large-diameter cores 2. This strongly coupled multi-core fiber is made by embedding a large-diameter core 2 and a sub-wavelength diameter core 3 in the inner cladding region 4 , and covering the outer cladding region 5 on the inner cladding region 4 . The core diameter of the large-diameter core 2 is 3 μm, the core diameter of the sub-wavelength diameter core 3 is 100 nm, the shape of the inner cladding region 4 is rectangular, the size is 60 μm×40 μm, and the diameter of the outer cladding is 125 μm. The refractive index of the large core diameter 2 and the sub-wavelength diameter core 3 are both 1.458, the refract...

Embodiment 2

[0026] The difference between embodiment 2 and embodiment 1 is that the sub-wavelength diameter core 3 is not doped, and the large core diameter core 2 is phosphate glass doped with 2wt% ytterbium oxide, and doped with aluminum ions to improve performance.

Embodiment 3

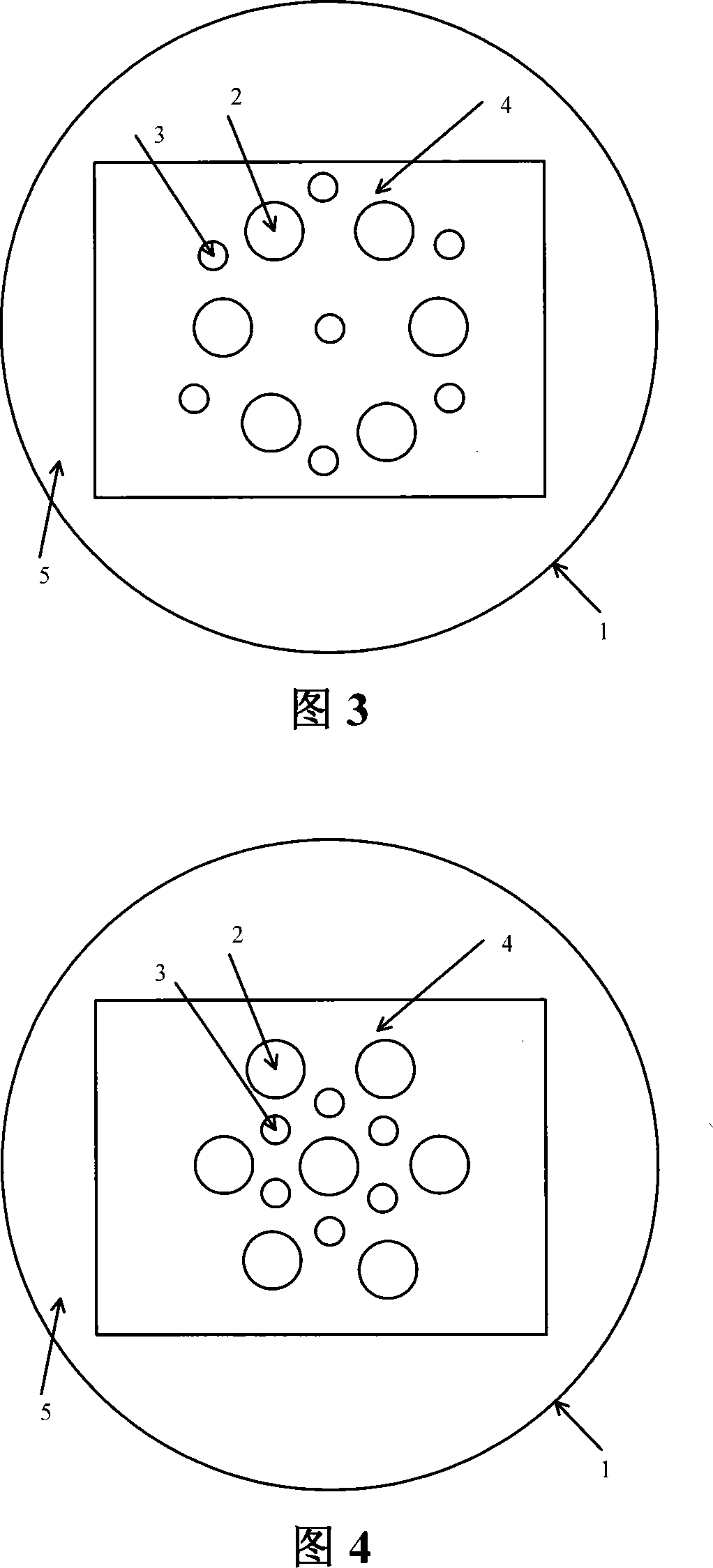

[0028] Fig. 2 is a schematic cross-sectional view of an optical fiber according to Embodiment 3 of the present invention. This is a strongly coupled multi-core fiber in which the large-diameter cores 2 in the inner cladding region 4 are arranged in a pentagon, and the sub-wavelength diameter core 3 is located among the five large-diameter cores 2 . This strongly coupled multi-core fiber is made by embedding a large-diameter core 2 and a sub-wavelength diameter core 3 in the inner cladding region 4 , and covering the outer cladding region 5 on the inner cladding region 4 . The diameter of the large-diameter core 2 is 3 μm, the sub-wavelength diameter core 3 is 100 nm, the shape of the inner cladding region 4 is rectangular, and the size is 60 μm×40 μm, and the diameter of the outer cladding region 5 is 125 μm. The refractive index of the large core diameter 2 and the sub-wavelength diameter core 3 are both 1.458, the refractive index of the inner cladding region 4 is 1.45, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com