Technique used for ABS plastic substrate chemical plating pre-processing

An ABS plastic, chemical plating technology, applied in liquid chemical plating, metal material coating process, coating and other directions, can solve the problems of low operability, unsuitable for industrial production, complex composition of treatment liquid, etc., to achieve operability The effect of high performance, reduced processing steps, and reduced difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

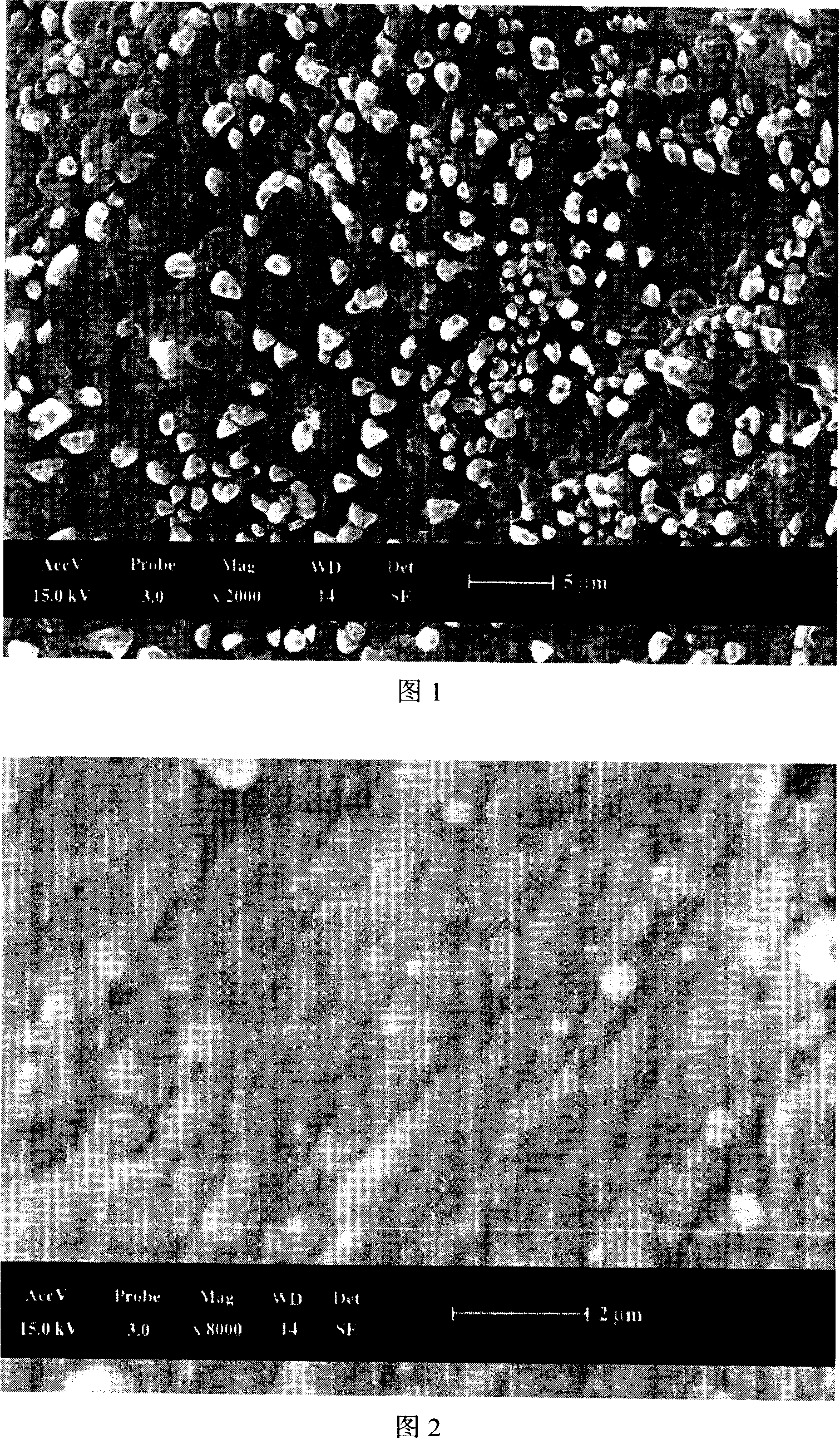

[0031] Put the degreased ABS test piece into the microetching solution prepared by 36% hydrogen peroxide and 98% concentrated sulfuric acid with a volume ratio of 1:2 for 5 minutes, wash with water, and then immerse in the microetching solution containing 0.5g chitosan CTS powder. Treat in 100ml 1% acetic acid solution for 10min, then dry at 50°C for 80min. into the PdCl 2 Adsorb in a solution containing 0.1g / L HCl 2.0g / L for 15min at a temperature of 50°C, wash with water, and use NaH 2 PO 2 The 5g / L solution was reduced for 5 minutes, washed at 40°C, and then placed in the electroless nickel plating solution for electroless plating.

[0032] The obtained coating is uniform and dense, and has good bonding force.

Embodiment 2

[0034] Change the volume ratio of hydrogen peroxide and sulfuric acid in Example 1 to 1:4, and all the other conditions are the same as in Example 1.

[0035] The obtained coating is uniform and dense, and has good bonding force.

Embodiment 3

[0037] Change the mass of the CTS powder in Example 2 to 0.2 g, and the film-forming treatment time to 5 minutes, and the other conditions are the same as in Example 2.

[0038]The obtained coating is uniform and dense, and has good bonding force.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com