Low-pollution compound reverse osmosis membrane

A reverse osmosis membrane, low-pollution technology, applied in the field of water treatment, can solve the problems of loss of protective layer, colloidal particle pollution, biochemical pollution, etc., and achieve the effect of improving anti-pollution performance, large water flux, and high desalination rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

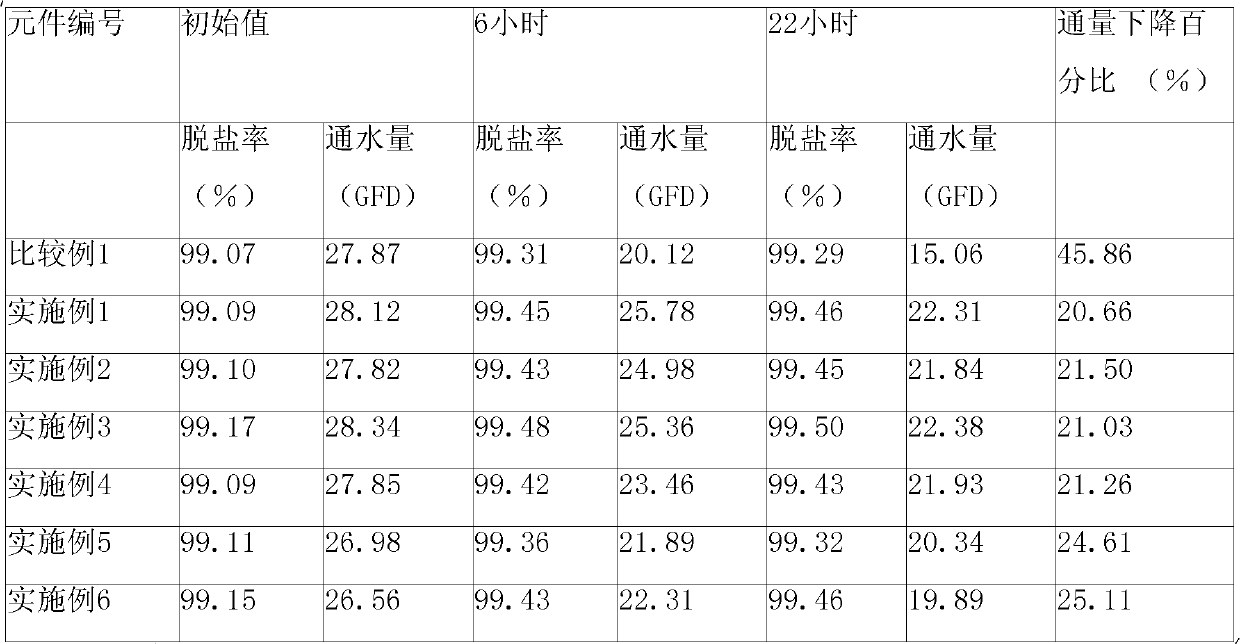

[0021] The difference from Comparative Example 1 is that a cross-linked PVA layer is added on the polyamide layer to obtain the final composite reverse osmosis membrane. The cross-linked PVA layer is that 3kg of polyvinyl alcohol (PVA) with an average degree of polymerization of 1000 (n=1000) and a degree of saponification of 75% is dissolved in 97kg of hot water at 60°C, and after mixing well, add 0.5kg Glutaraldehyde and 0.2kg of hydrochloric acid, continue to stir to make it react fully, apply the solution obtained from the reaction on the polyamide layer, and then dry it. For the composite reverse osmosis membrane of this example, its contact angle was measured to be 22°, and the same test method as that of Comparative Example 1 was adopted, and the obtained results are shown in Table 1.

Embodiment 2

[0023] Except that the polyvinyl alcohol (PVA) in Example 1 is replaced by polyvinyl alcohol (PVA) with an average degree of polymerization of 500 (n=500) and a degree of saponification of 75%, the same operation as in Example 1 is used to prepare Composite reverse osmosis membrane. The contact angle was measured to be 21°, and then the same test method as in Comparative Example 1 was adopted, and the obtained results are shown in Table 1.

Embodiment 3

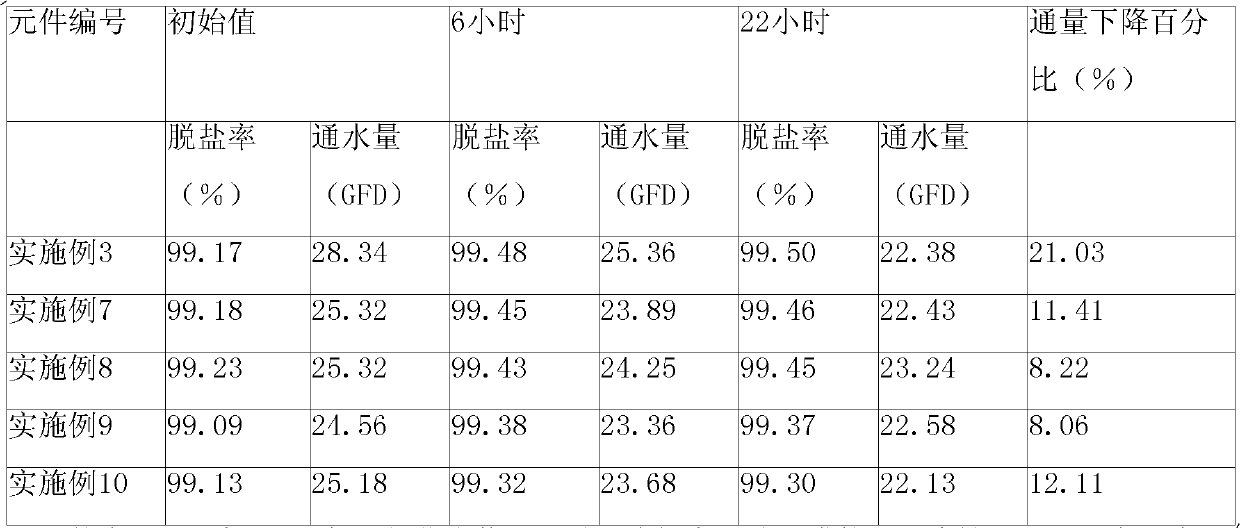

[0025] Except that 0.8 kg of glyoxal was used instead of 0.5 kg of glutaraldehyde, a composite reverse osmosis membrane was prepared by the same operation as in Example 1. Measure its contact angle to be 20°, then adopt the same test method as Comparative Example 1, and the obtained results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com