Linear motor radiator

A technology of linear motors and coolers, which is applied in the direction of cooling/ventilation devices, electrical components, electromechanical devices, etc., which can solve the problems of large motor operation noise, complicated manufacturing process and assembly process, and reduced linear motor slot fill rate, so as to achieve cooling Fast, compact, space-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

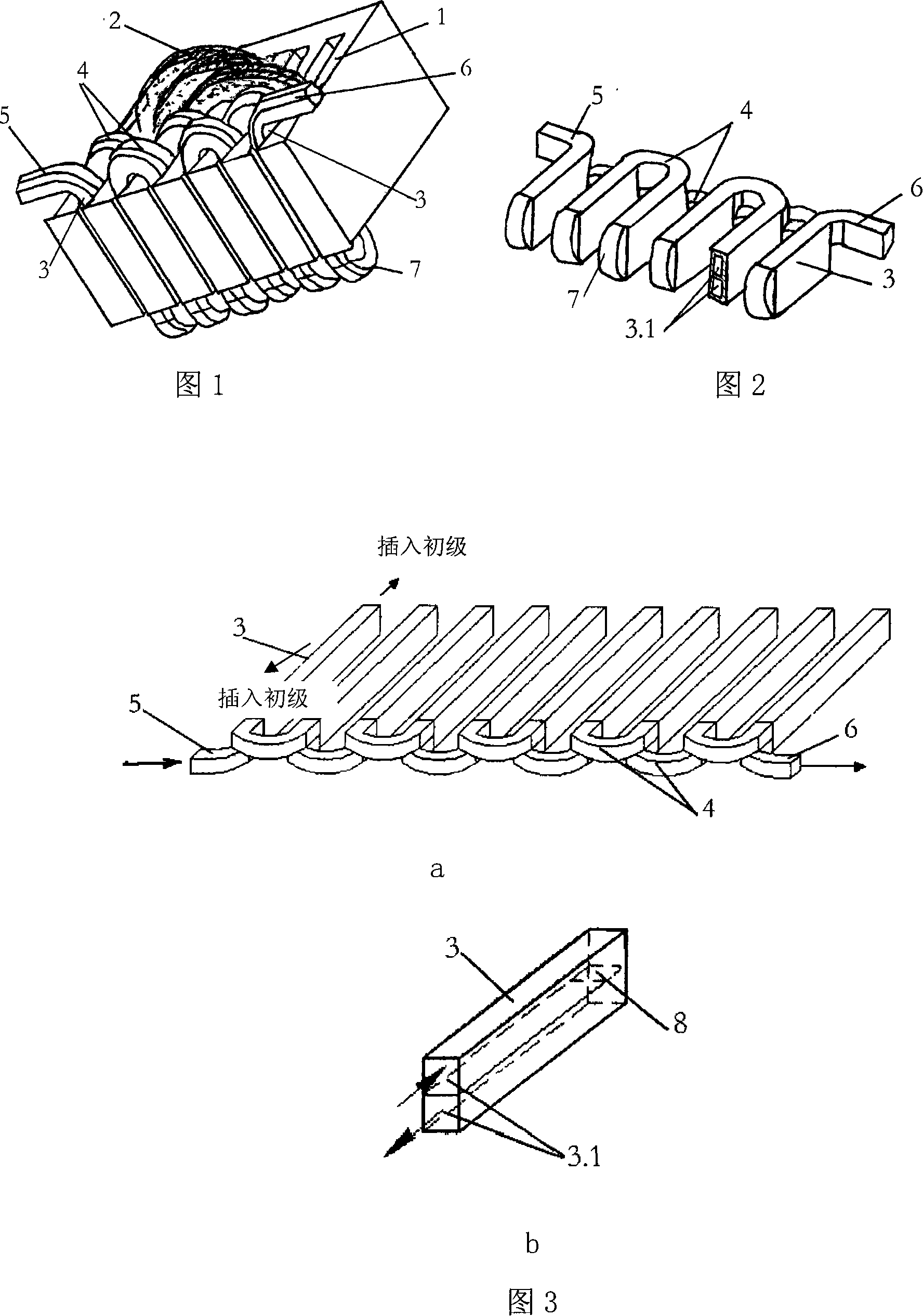

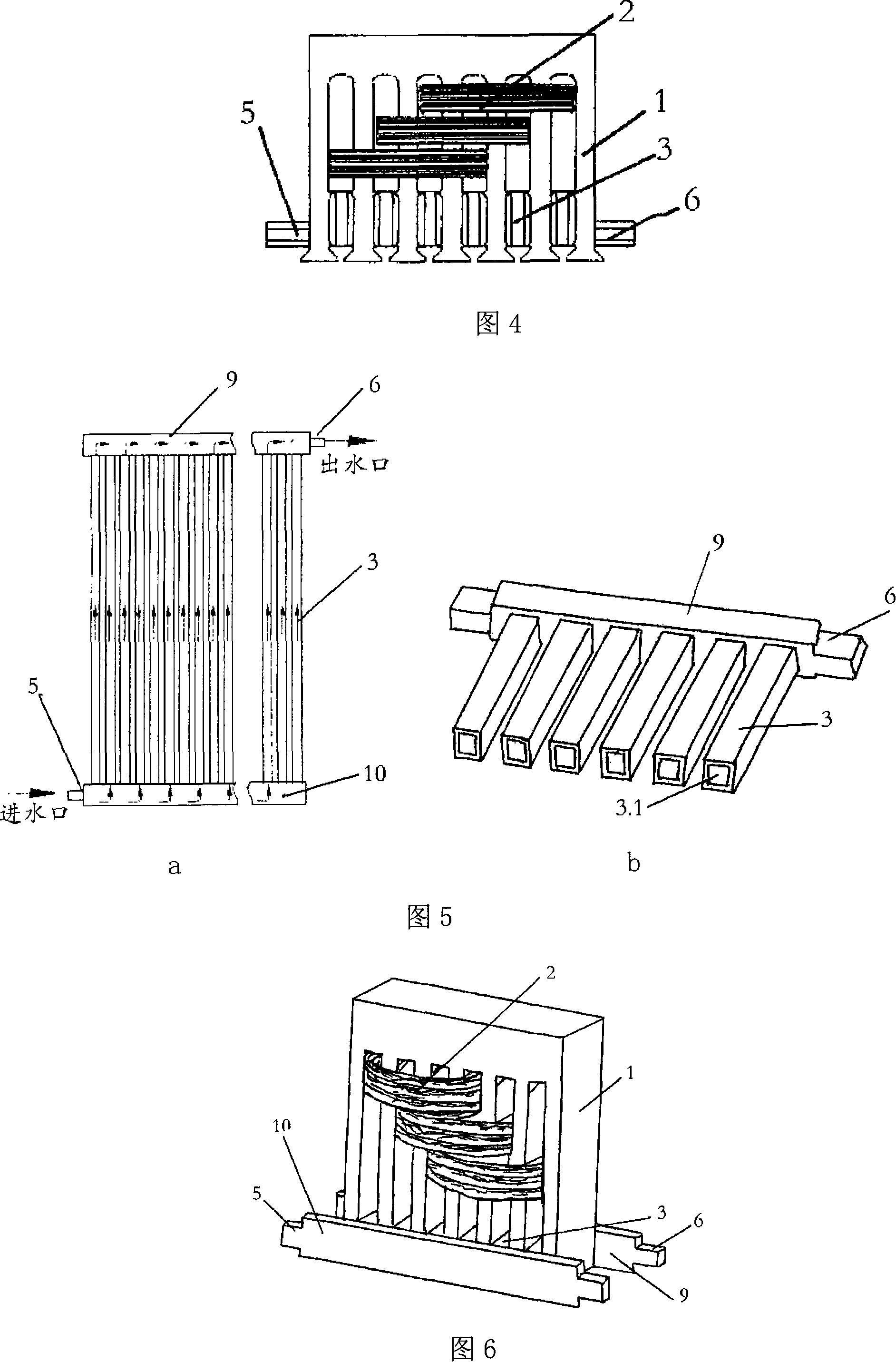

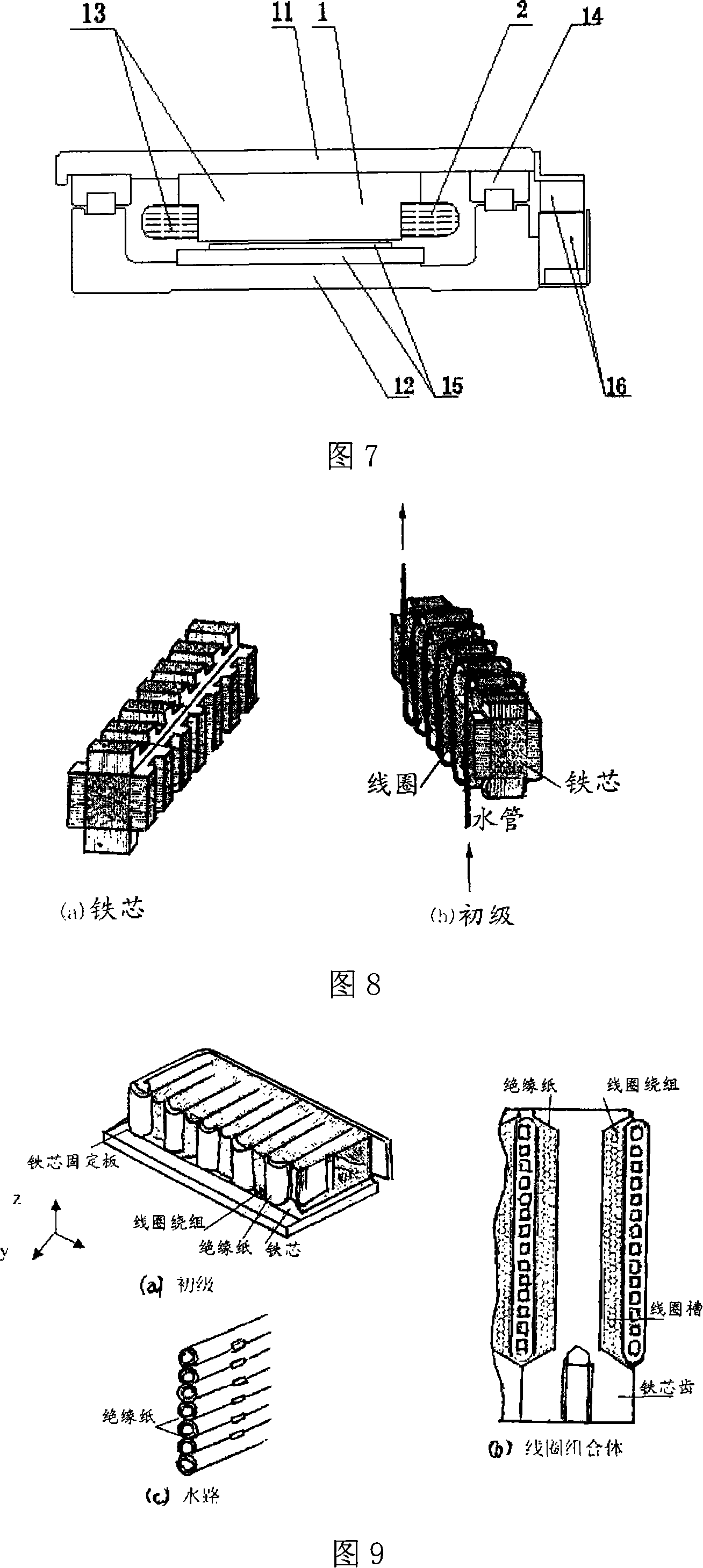

[0027] The invention provides a linear motor liquid cooler with fast cooling speed, high efficiency, compact structure and space saving. The cooler is a plug-in inner cooler, and the cooling device for a linear motor will be described in detail with reference to the accompanying drawings. In the assembly diagram of the internal cooling cooler shown in Figure 1, the cooling water pipe 3 is inserted into the wire release slot of the iron core 1 and is close to the coil 2. The liquid channel 3.1 is connected by the external connector 7, and then forms a cooling circuit with the water inlet 5 and the water outlet 6 of the cooling liquid; Good filler.

[0028] The cooling water pipe has two kinds of dual cooling liquid channels (as shown in Fig. 2 and Fig. 3(a) and (b)) and single cooling liquid channel (as shown in Fig. 5).

[0029] The communication of the dual coolant channels is in the form of an external channel communicator 7 (as shown in FIG. 2 ) and a communication hole 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com