Cigarette label high-speed intaglio printing water-based ink

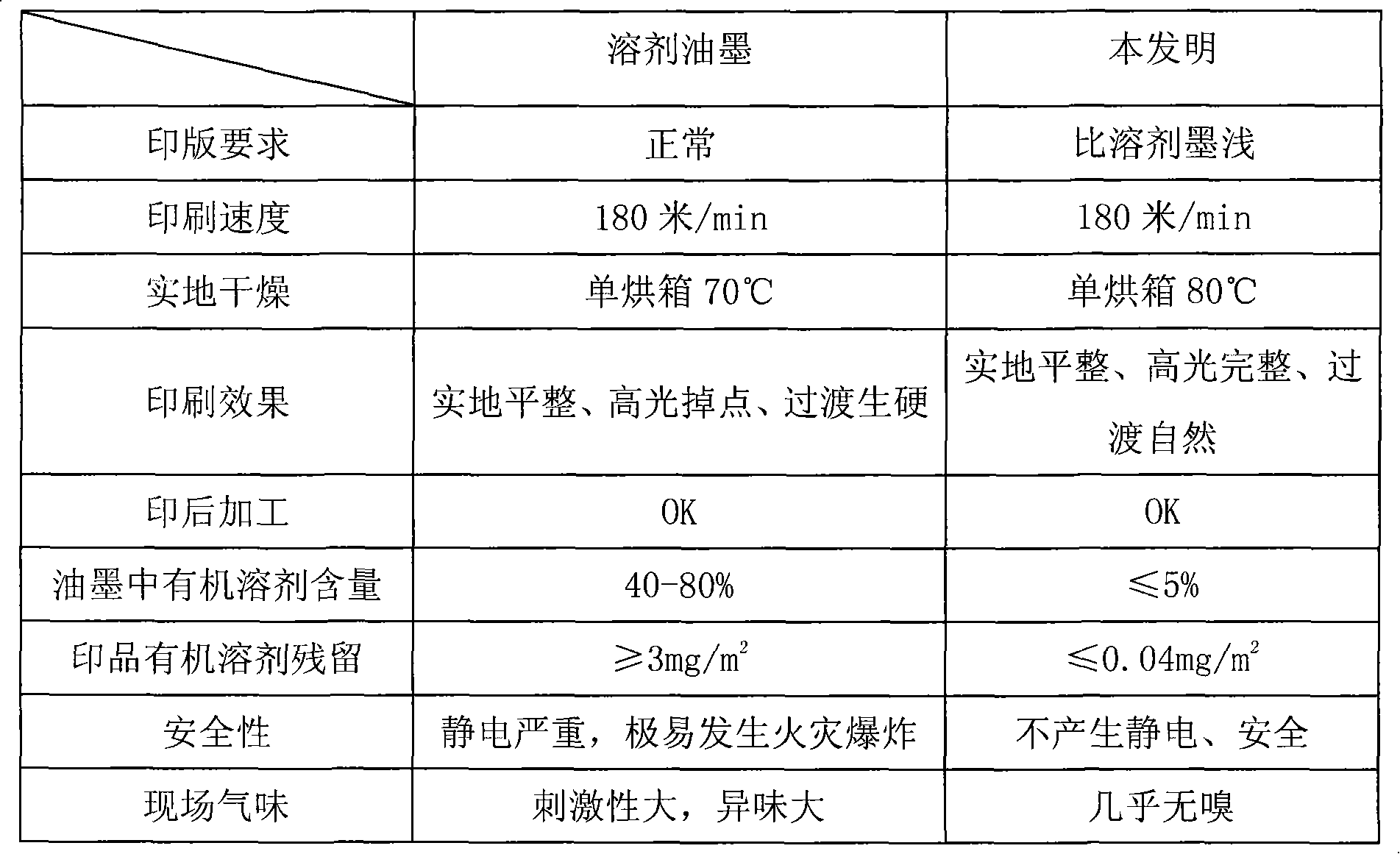

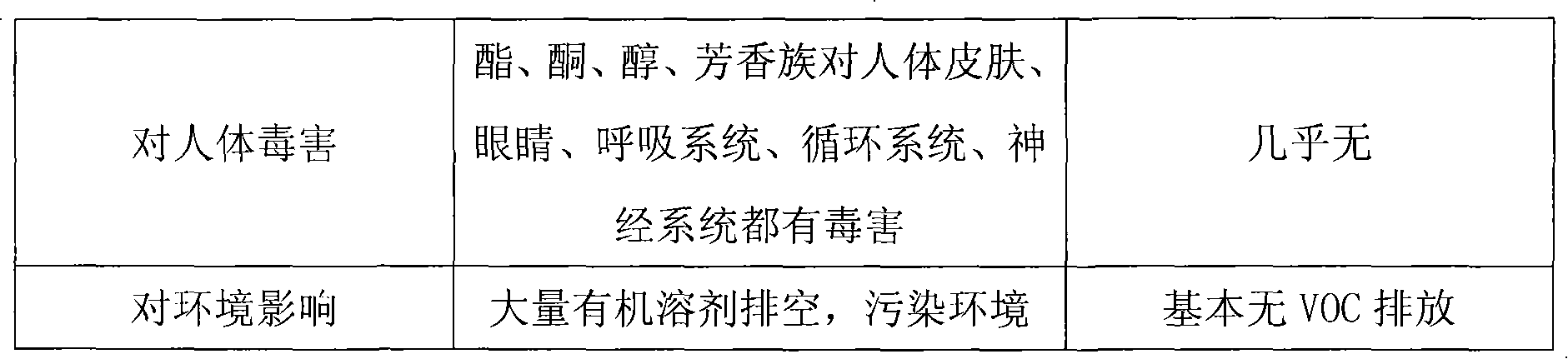

A water-based ink, high-speed technology, used in ink, printing, printing devices, etc., can solve the problems of hidden safety hazards, user body toxicity, and high organic solvent concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A high-speed gravure printing water-based ink for cigarette labels, which is composed of the following components, and the dosage is percentage by weight:

[0028] Water-based acrylic emulsion (model NeoCrylBT-44) 45%

[0029] Acrylic solid resin (model is CarbosetGA-1160) 3%

[0030] Substrate wetting agent (model is Wet500) 0.5%

[0031] Defoamer (model is Foamex1488) 0.2%

[0032] PH regulator 0.8%

[0033] Pigment Preforms 25%

[0034] Ethanol 5%

[0035] Water 20.5%

[0036] The preparation method is as follows: firstly take acrylic solid resin, defoamer, PH regulator and water and add them into the kettle according to the ratio in the technical scheme and stir; after heating up, keep warm at 60°C until the components in the kettle are completely dissolved into a clear liquid; Then add the pigment preform and ethanol and stir until completely dissolved. The pigment preform is an inorganic solvent; finally, add the water-based acrylic emulsion and substrate we...

Embodiment 2

[0038] A high-speed gravure printing water-based ink for cigarette labels, which is composed of the following components, and the dosage is percentage by weight:

[0039] Water-based styrene / acrylic emulsion (model JonCryl 8051) 10%

[0040] Acrylic solid resin (model is CarbosetGA-1160) 10%

[0041] Substrate wetting agent (model is Wet500) 0.2%

[0042] Defoamer (model is Foamex1488) 0.8%

[0043] Diethanolamine 5%

[0044] Organic Pigments 33%

[0045] Isopropanol 3%

[0046] water 38%

[0047] The preparation method is as follows: firstly take acrylic solid resin, defoamer, diethanolamine and water and add them into the kettle according to the ratio in the technical scheme and stir; after heating up, keep the temperature at 65°C until the components in the kettle are completely dissolved into a clear liquid; then Add the organic pigment and isopropanol and stir until completely dissolved. Finally, add the water-based styrene / acrylic emulsion and substrate wetting age...

Embodiment 3

[0049] A high-speed gravure printing water-based ink for cigarette labels, which is composed of the following components, and the dosage is percentage by weight:

[0050] Water-based polyurethane dispersion (model NeoRezR-984) 30%

[0051] Acrylic solid resin (model is Carboset GA-1160) 12%

[0052] Substrate wetting agent (model is Wet500) 0.4%

[0053] Defoamer (model is Foamex1488) 1.2%

[0054] Ammonia 1.8%

[0055] Organic Pigments 24%

[0056] Isopropanol 5%

[0057] Water 25.6%

[0058] The preparation method is as follows: firstly take acrylic solid resin, defoamer, ammonia water and water and add them into the kettle according to the proportion in the technical plan and stir; The organic pigment and isopropanol are stirred thoroughly until they are completely dissolved. Finally, the water-based polyurethane dispersion and substrate wetting agent are added and stirred well.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com